Production Method and Filter Comprising Non Woven Fabric and/or Filtering Injector Structures or Sheets Which are Obtained Using Said Method and Which are Intended for the Filtration and Which are Intended for the Filtration and Elimination of Legionella Pneumofila in any Installation at Risk From Legionella Pneumofila Proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

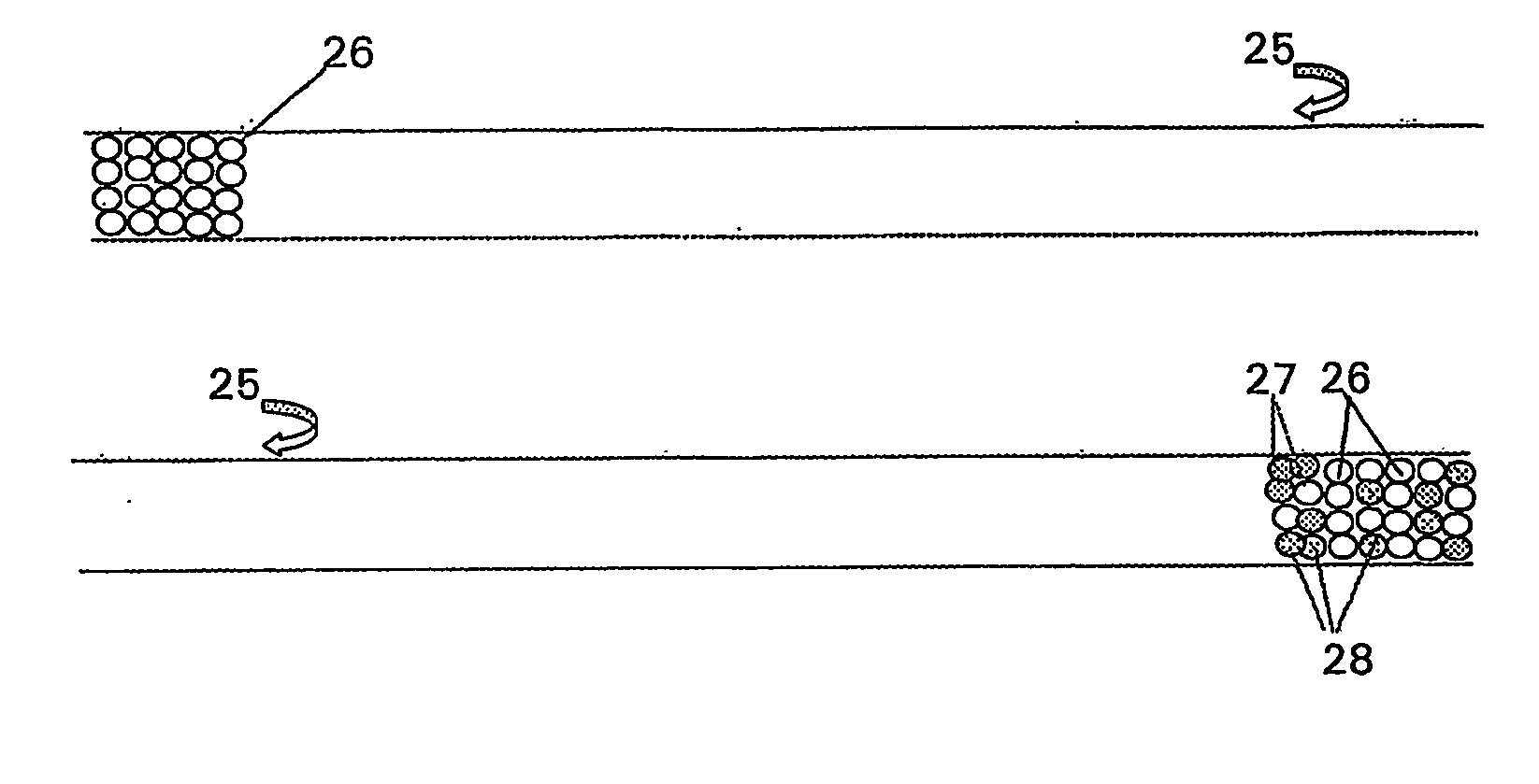

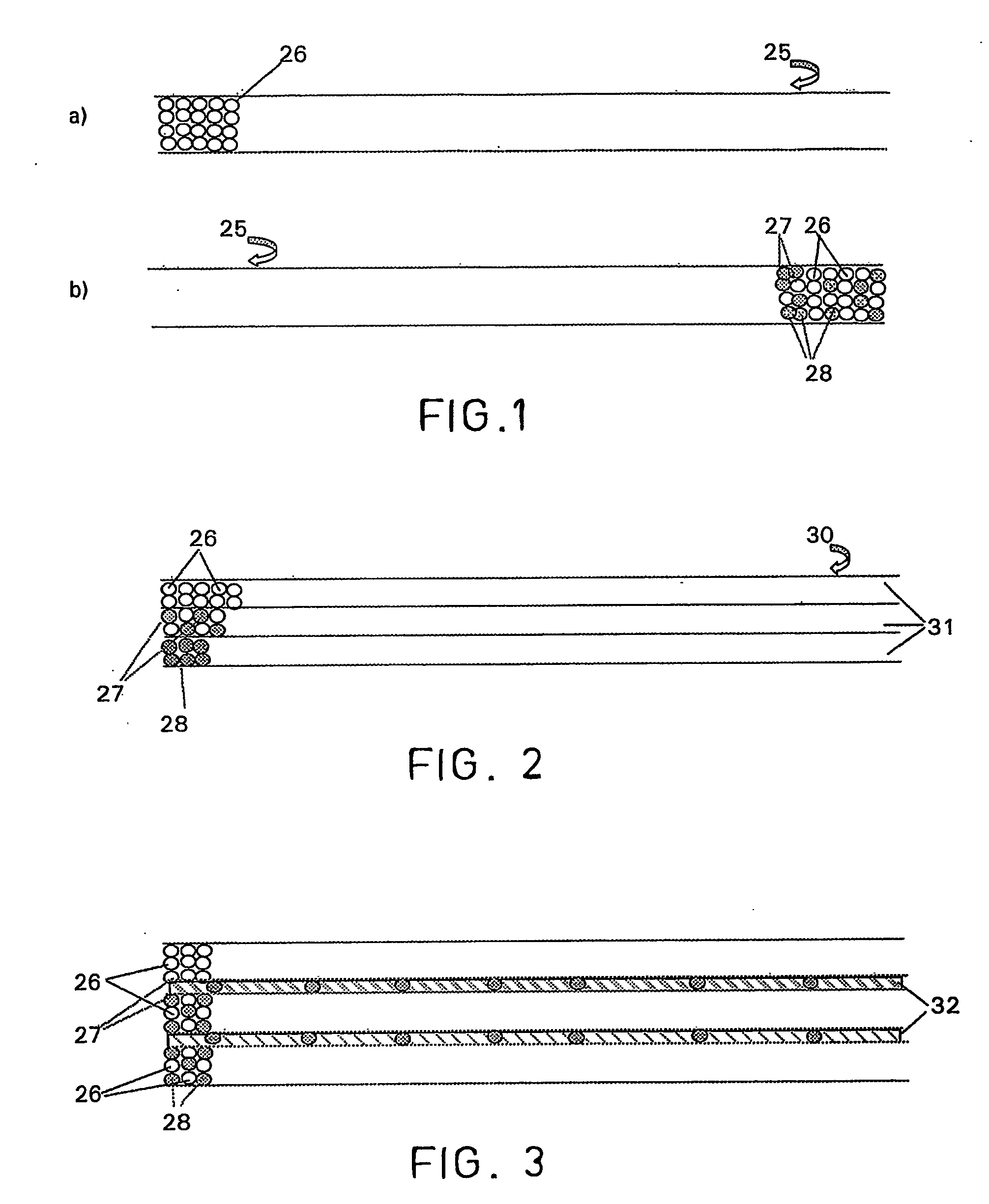

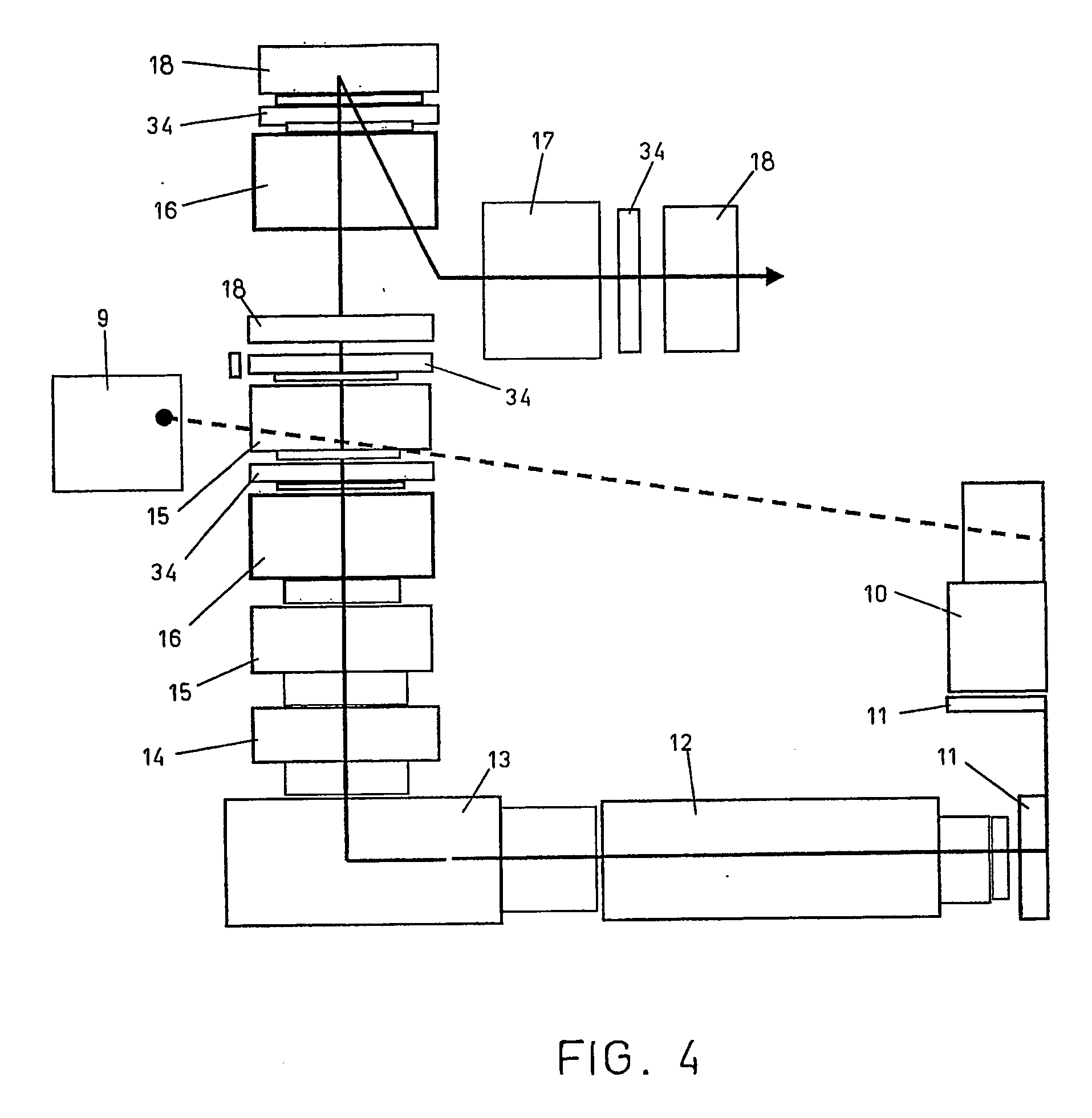

Method used

Image

Examples

Embodiment Construction

[0457] Non woven fabric filters and fabric filters with antiviral, algaecide, fungicide and bactericide properties claimed in this patent (Legionella, Klebsiella pneumoniae, Pseudomonas aeroginosa, Staphylococcus aureus, Bacillus cereus, Vibrio para hacmolyticus, Proteus Vulgaris, Salmonella typhimorium, Staphylococcus epidermidis, Escherichia coli, Serratia marcescens and Burkholderia cepacia, anthrax, A and B flu virus and Avian flu or acute serious respiratory syndrome (ASRS), fungus such as Phytophthora cinnamoni) made in non woven fabrics and woven fabrics from fibres claimed in this family of patents, treated with compounds or combinations of compounds listed in this patent, such as: [0458] Anti-Pseudomonas, Klebsiella, Legionella and Staphylococcus filters made from synthetic fibres treated with Triclosan and BCD. [0459] Anti A and b flu filter with ribavirune. [0460] Anti Phytophtora cinnamoni filter made from natural and synthetic fibre mix treated with copper compounds. [0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com