Flexible plastic container

a flexible, plastic container technology, applied in the direction of flexible containers, bags, packaging, etc., can solve the problems of fluid trapped in the folds of bags, vacuum pump systems, gravity dispensing bags and vacuum pumps,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] While this invention is susceptible of various embodiments, herein will be described in detail with the accompanying figures preferred embodiments of the invention. The present disclosure is to be considered as an exemplification of the principles of the invention and is not intended to limit the broad aspect of the invention to the embodiments illustrated and described.

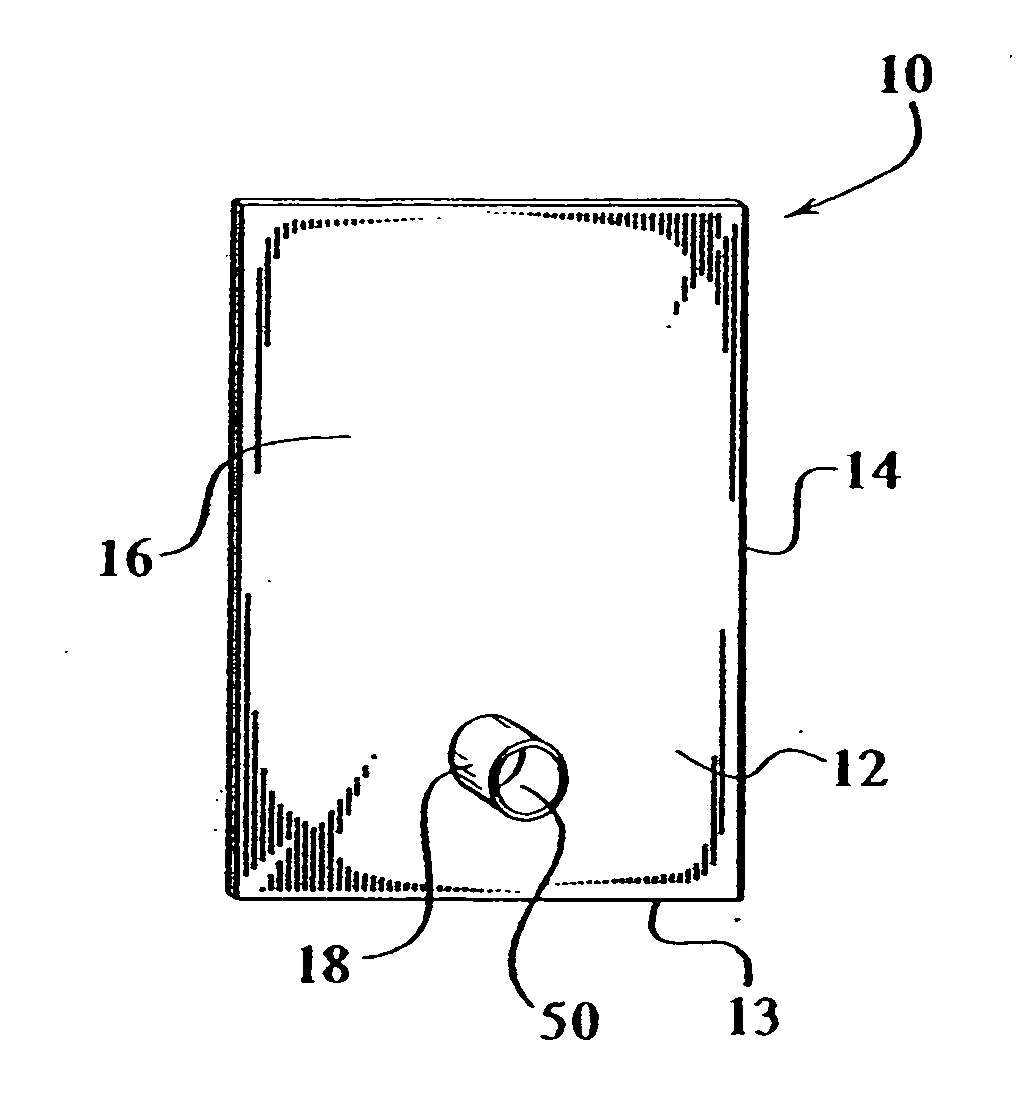

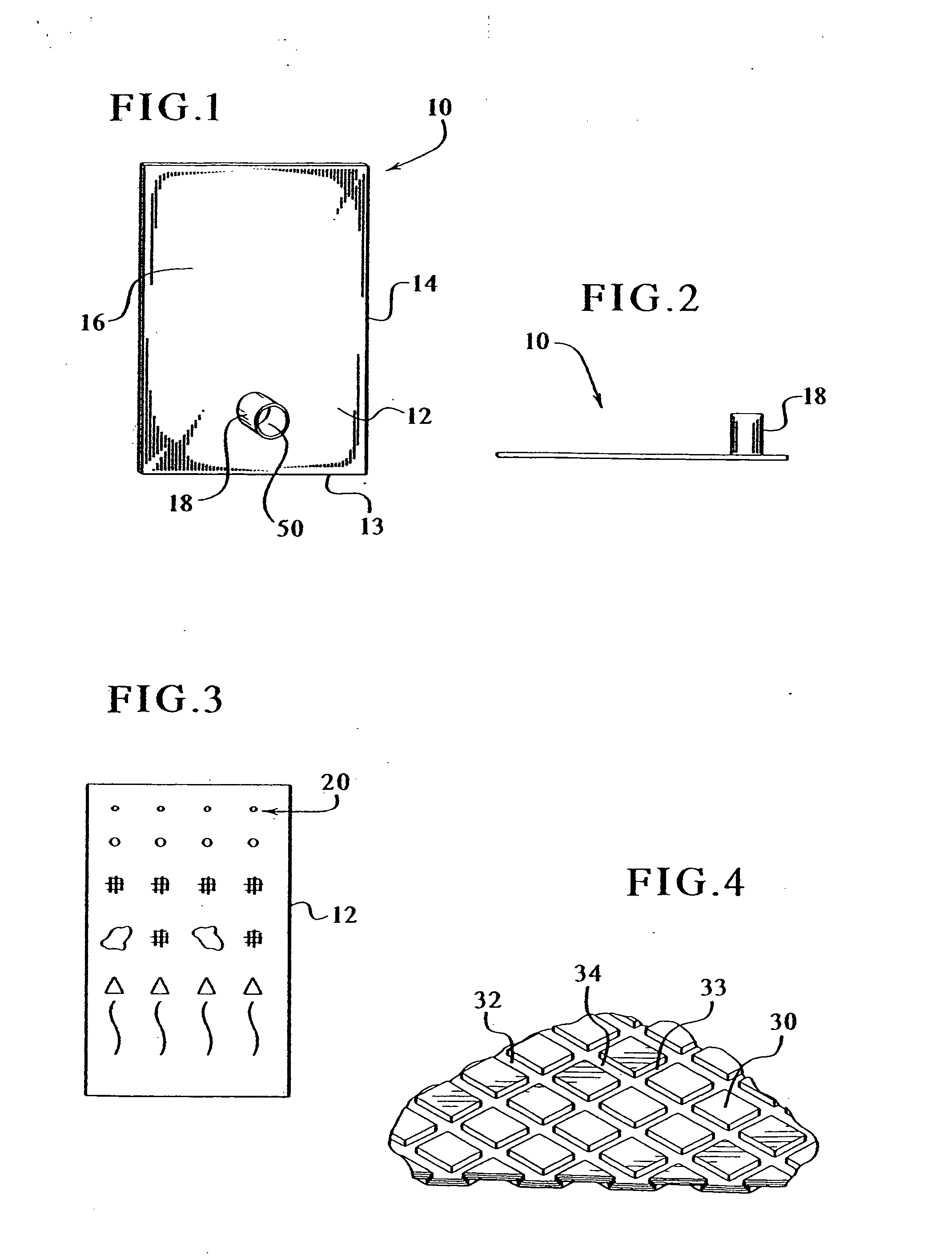

[0027]FIGS. 1 and 2 show a flexible container assembly 10 having a first sidewall 12 and a second sidewall 13 attached at peripheral edges 14 to define a fluid tight chamber 16. A fitment in the form of a spout 18 is attached to a surface of one of the sidewalls 12 and 13 and provides fluid flow access to the chamber 16. In a preferred form of the invention, the first and second sidewalls 12 and 13 are a flexible polymeric material having a modulus of elasticity of less than 50,000 psi. The sidewalls preferably are made from materials such as homopolymers and copolymers of polyolefins, polyamides, polyesters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com