Method and apparatus for detecting water in a fluid media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

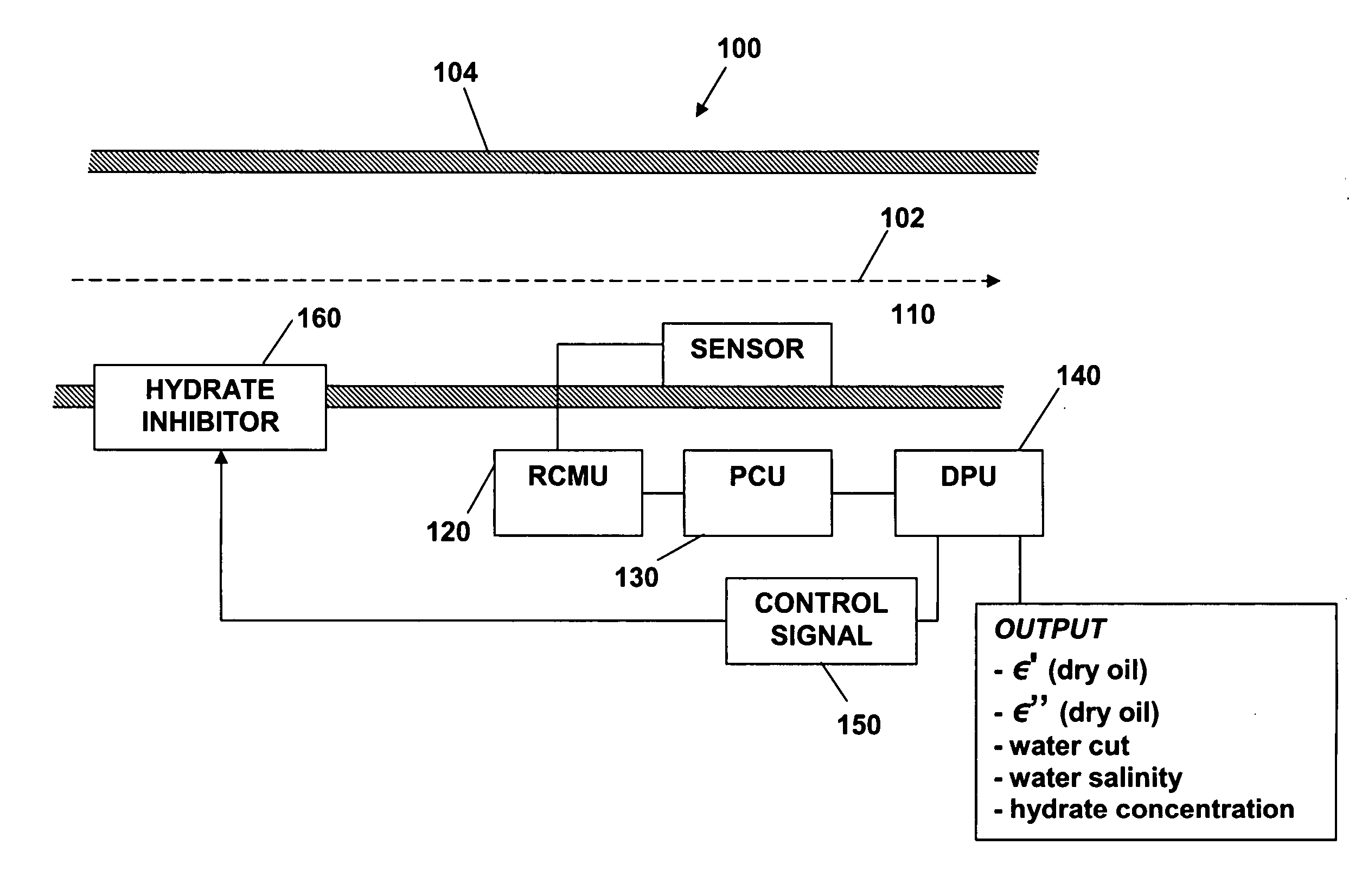

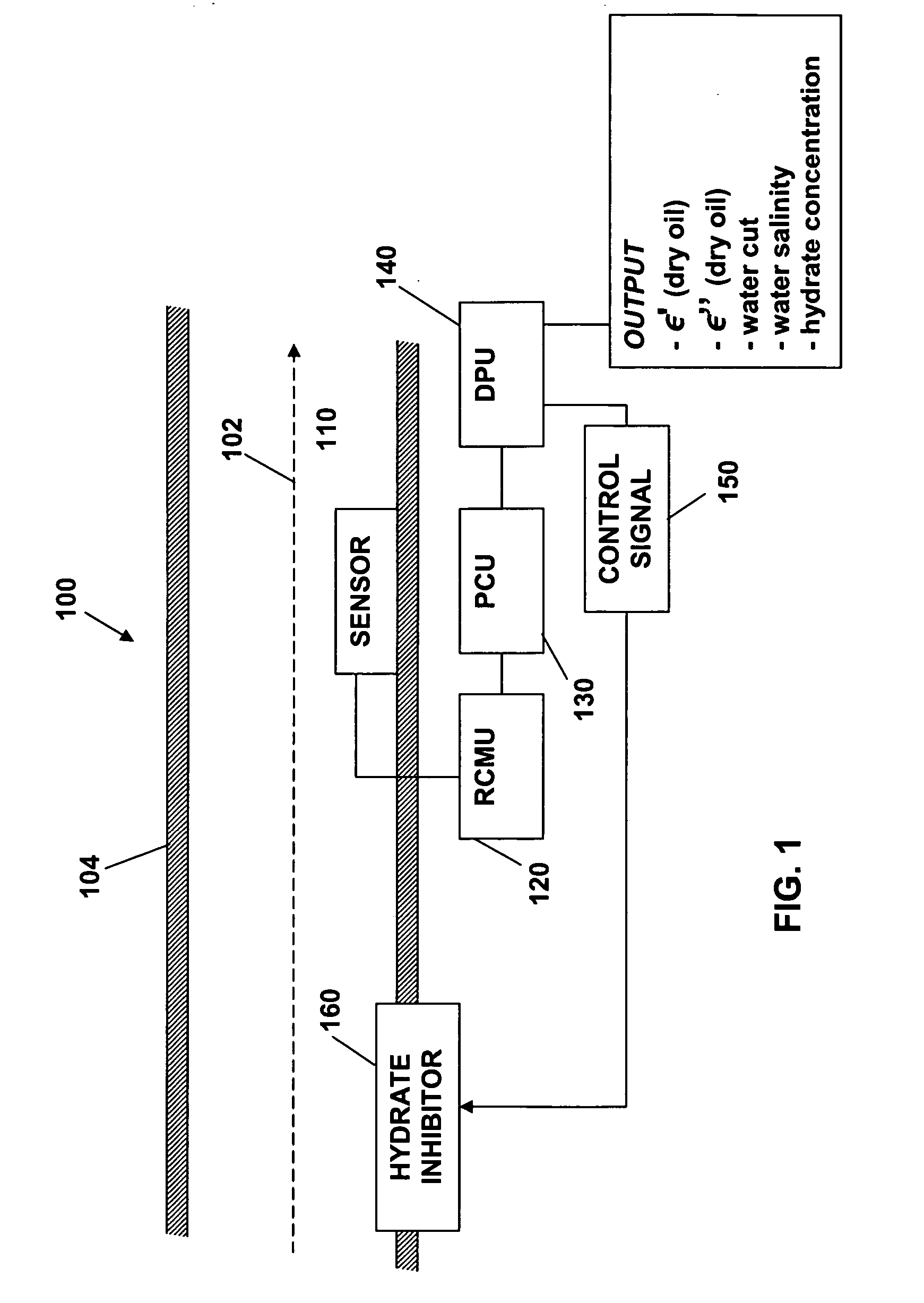

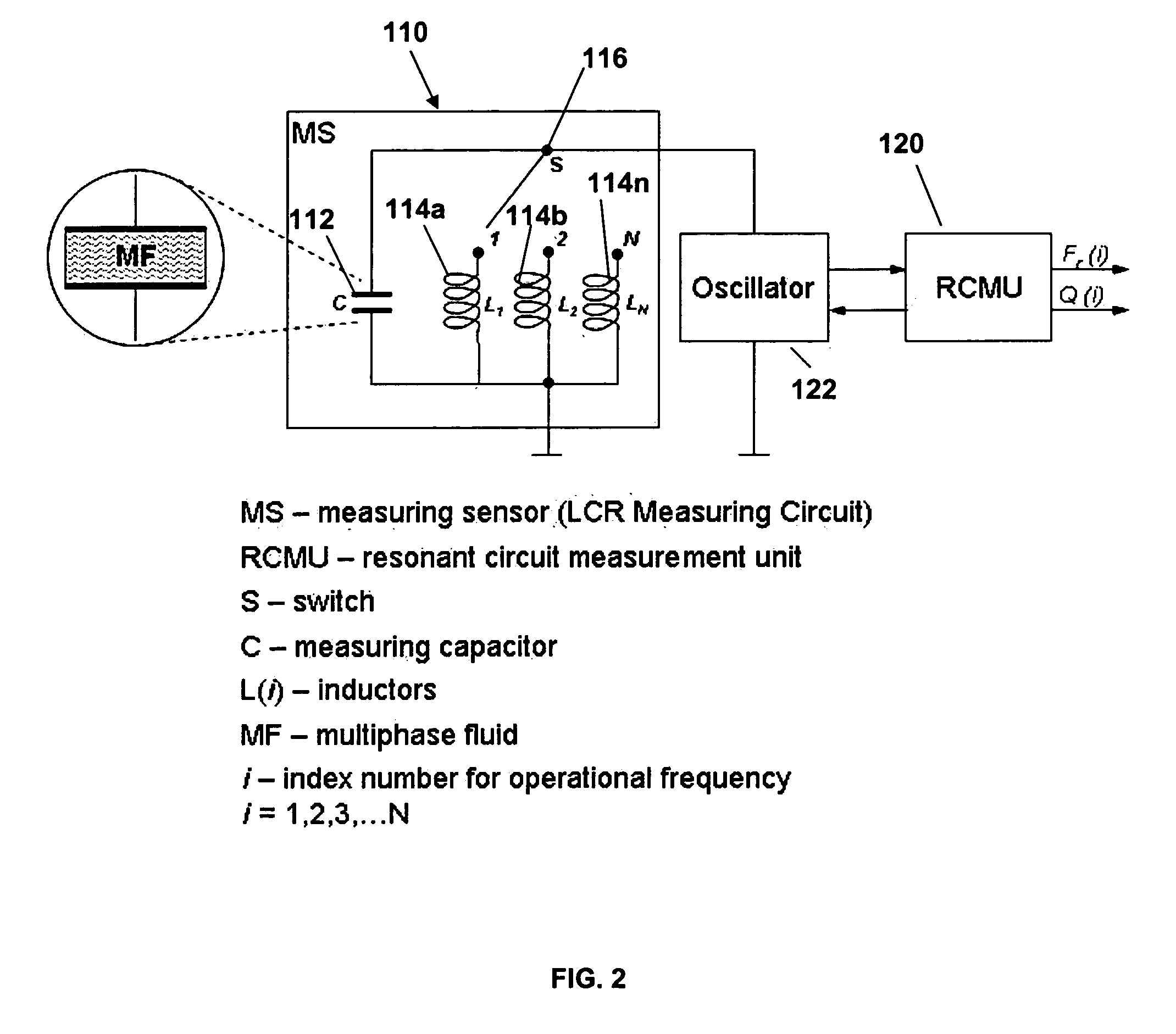

[0019] In aspects, the present invention presents advancements over the prior art in that the teachings it allow direct and accurate measurement of the complex permittivity of a given multiphase fluid. In exemplary embodiments, the methods include measuring the complex permittivity at two or more selected frequencies. These methods are not dependent upon obtaining an API gravity upon which a dielectric constant will be based. Thus, these methods will determine permittivity with greater accuracy than prior art arrangements, which in turn, will lead to the determination of the amount of water or presence of hydrates with greater accuracy. While the teachings of the present invention can be advantageously adapted to a variety of applications, merely for simplicity the present invention will be discussed in the context of a flowing multiphase fluid hydrocarbon fluid such as crude oil. It should be appreciated that the present teachings can also be utilized in connection with standing in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com