Modular boat lift canopy assembly and kit

a module and canopy technology, applied in the field oftruss type framework canopies, can solve the problems of inability to easily adapt to the construction of canopy kits by unskilled users, inconvenient use, and high cost of canopy kits, and achieve the effects of simple adjustment of canopy overhang or length, easy construction, and simple adjustment of canopy position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

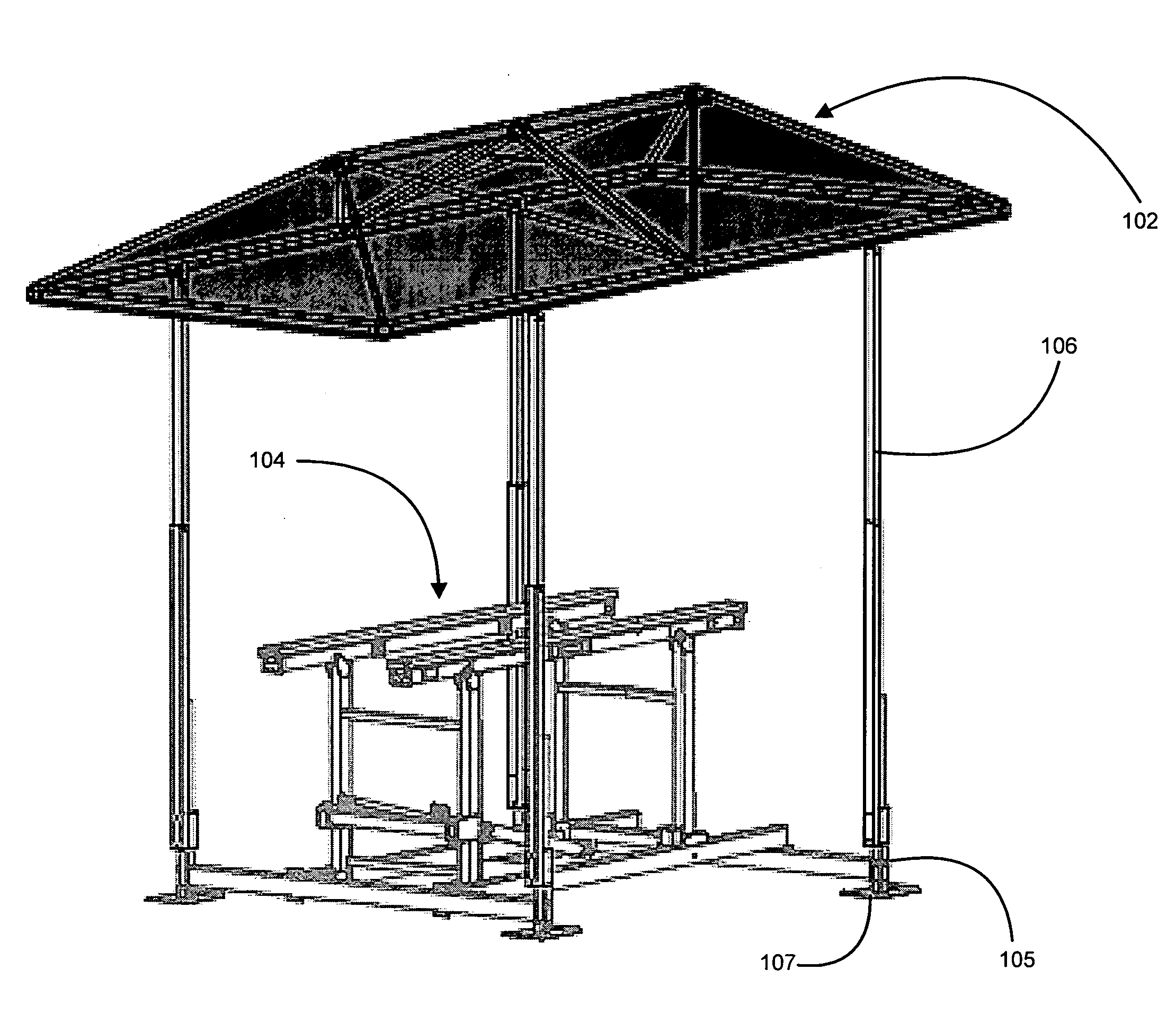

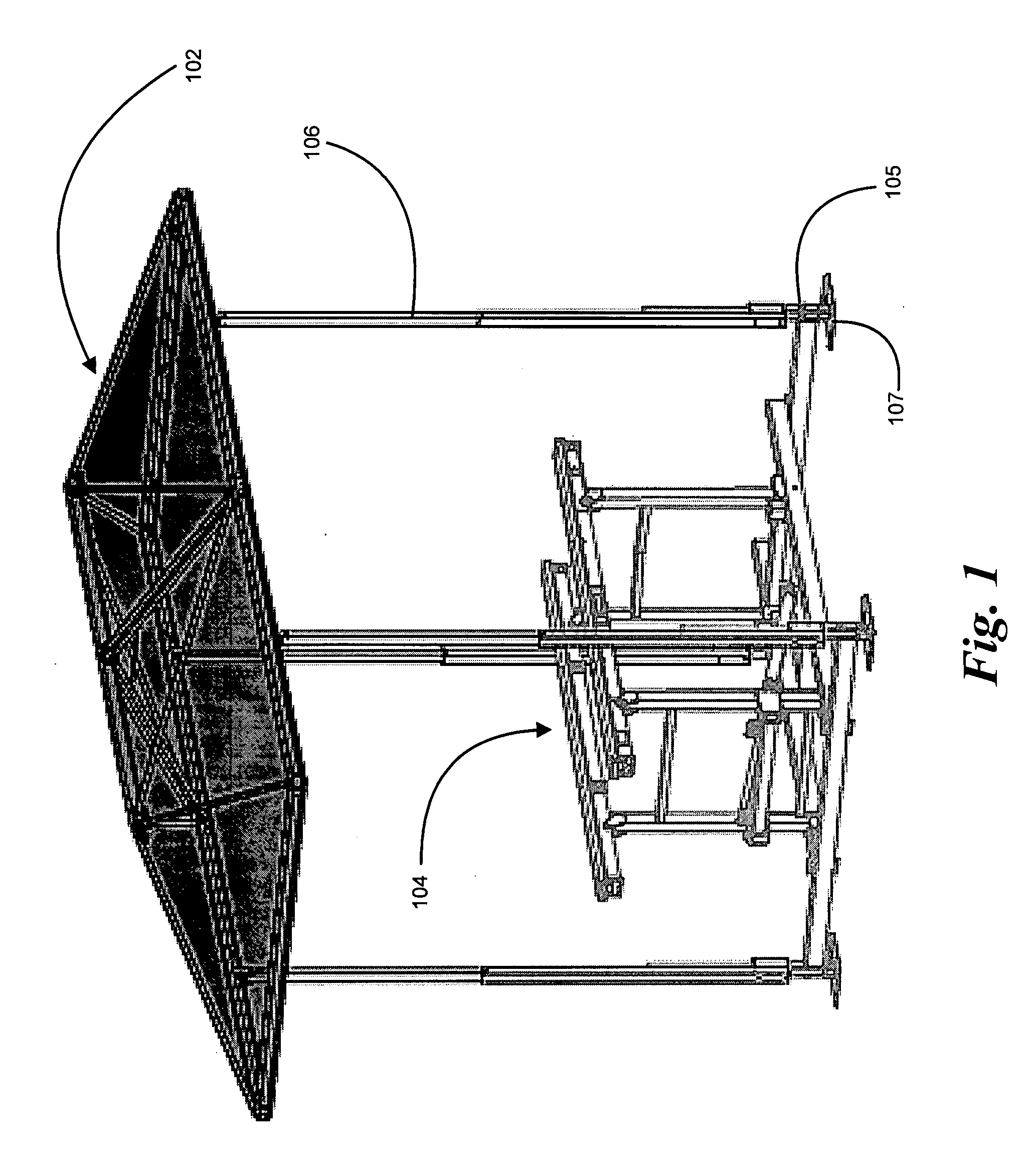

[0028] Turning now to FIG. 1, depicted is an embodiment of the present invention. Canopy 102 is constructed as a truss type framework over which is wrapped a canvas cover. Canopy 102 supports its canvas cover over a watercraft lift 104, standing upon upright members 106, the canopy configured to sit upon legs 105 terminating in feet 107. Lift 104 may be any form of watercraft lift designed to be affixed to the bottom of a body of water, such as described in U.S. Pat. No. 5,908,264 to Hey or U.S. Pat. No. 5,184,914, issued to the inventor of the present invention and which is incorporated herein by reference. Alternatively, lift 104 may be a floating lift as described in U.S. Pat. No. 5,485,798 to Samoian et al., or U.S. patent application Ser. No. 10 / 816,992 by the inventor of the present invention, incorporated herein by reference. Legs 105 may be dedicated to canopy 102, or in the alternative legs 105 may serve as supports for both canopy 102 and lift 102.

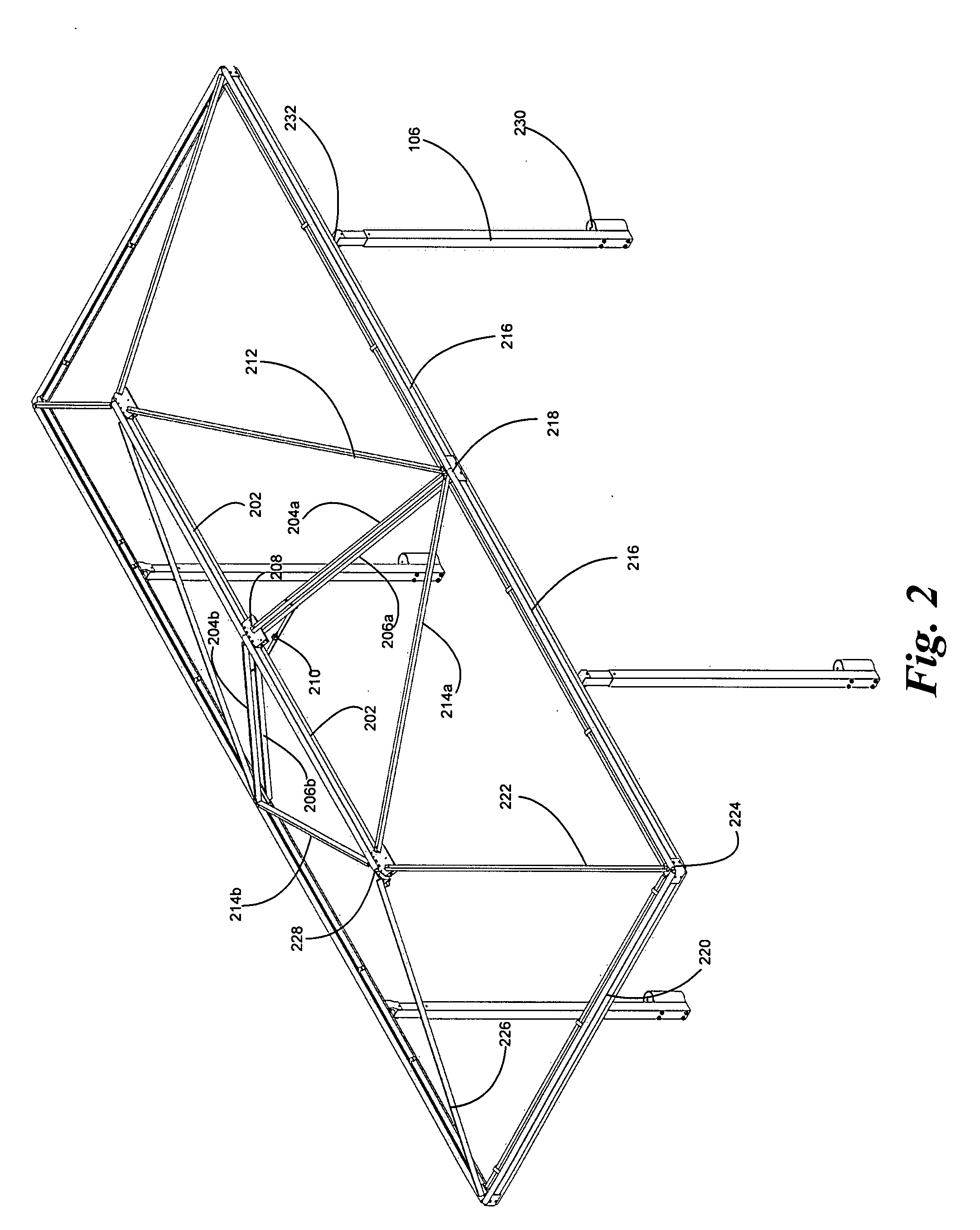

[0029] Turning now to FI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com