Apparatus and method of fabricating thin film pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

[0042]With reference to FIGS. 3 to 5, embodiments of the invention will be explained as follows.

[0043]A fabricating method and apparatus of a thin film pattern according to one preferred embodiment of the invention uses an etch resist solution that includes a surfactant inclusive of an ethylene oxide fluorinated polymer. The etch resist solution including this surfactant has a stronger adhesive force with the print plate than with the blanket, thus it becomes possible to easily transfer the etch resist solution from the blanket to the print plate. As a result, the reliability of forming the thin film pattern by a resist printing method can be improved.

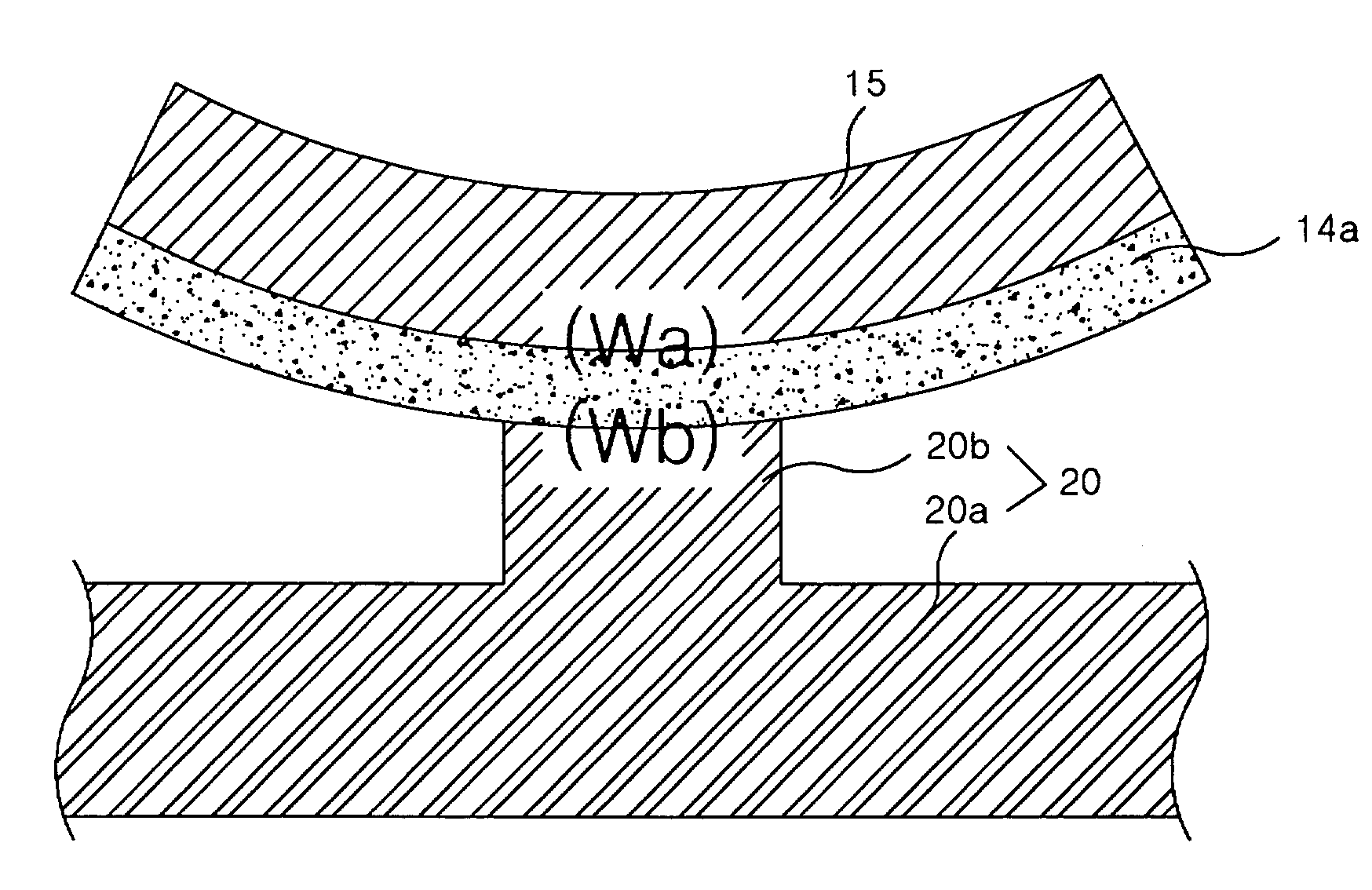

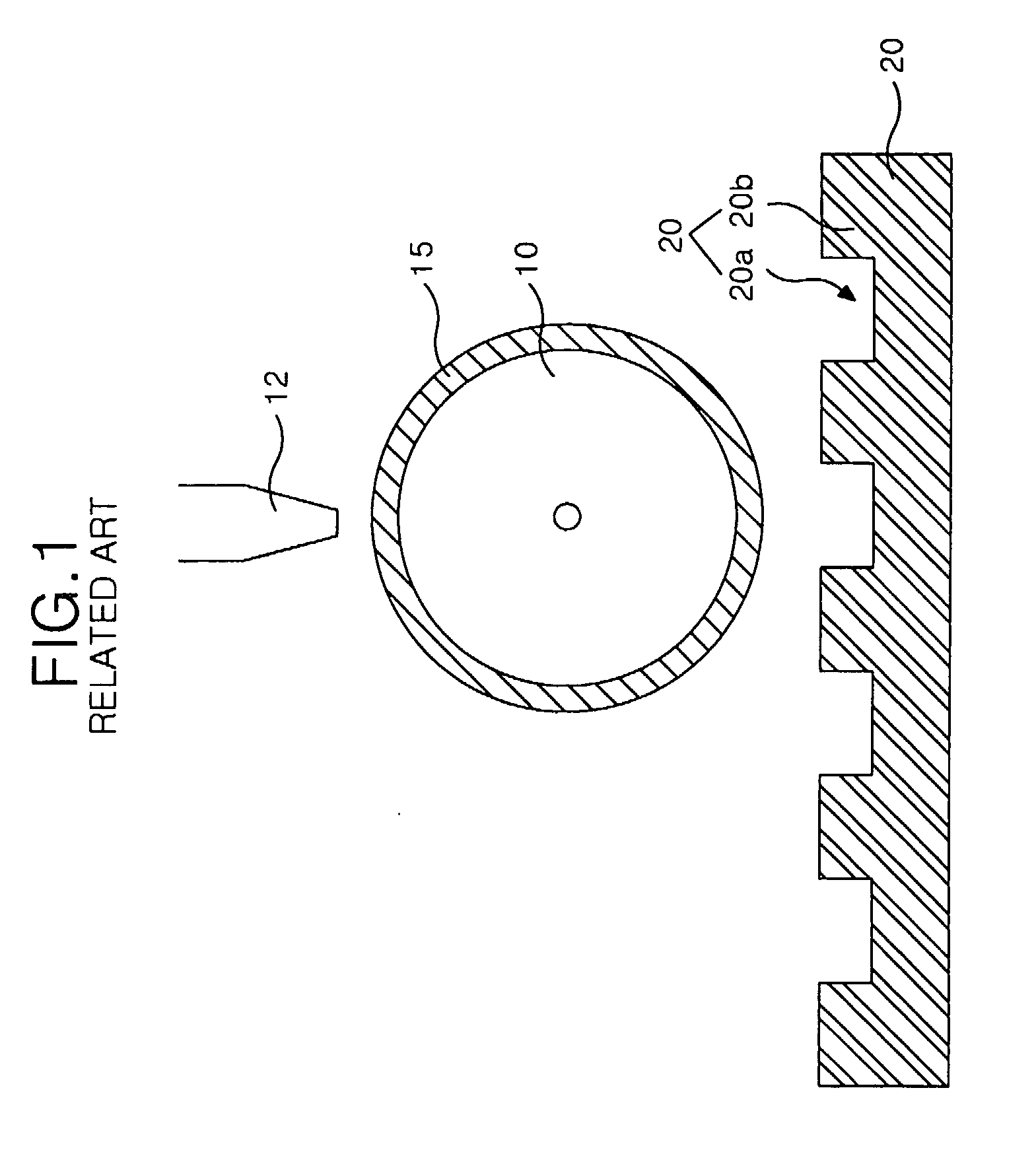

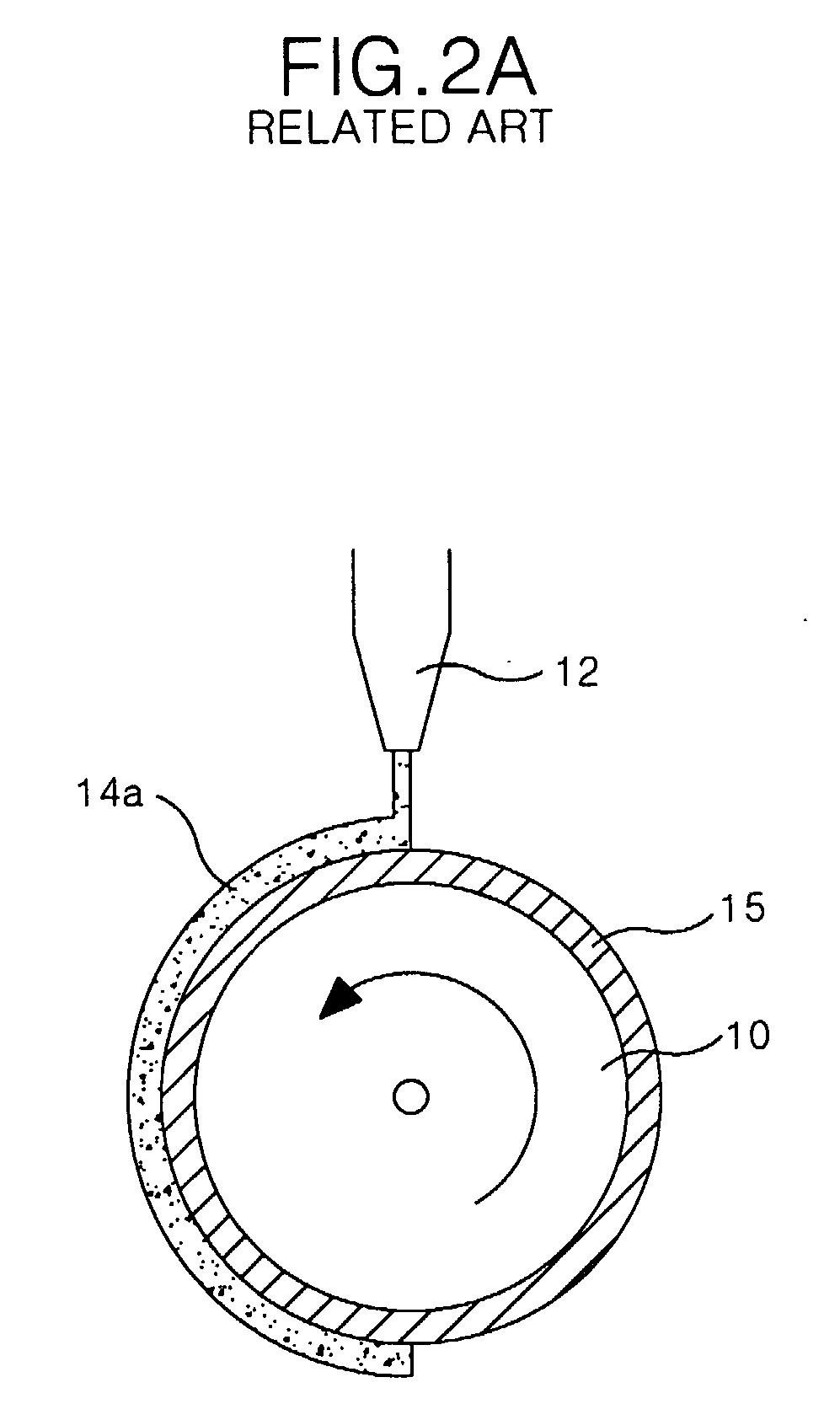

[0044]Referring to FIGS. 2A to 2D, the etch resist solution of the invention will be explained in detail in conjunction with a fabricating method of a thin film pattern by a resist pri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com