Supporting column having porous structure

a support column and porous structure technology, applied in the field of supporting columns, can solve the problems of aging, overloading a power supply, and generating noise, and achieve the effect of less susceptible to structural damage and favorable to heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

The First Embodiment

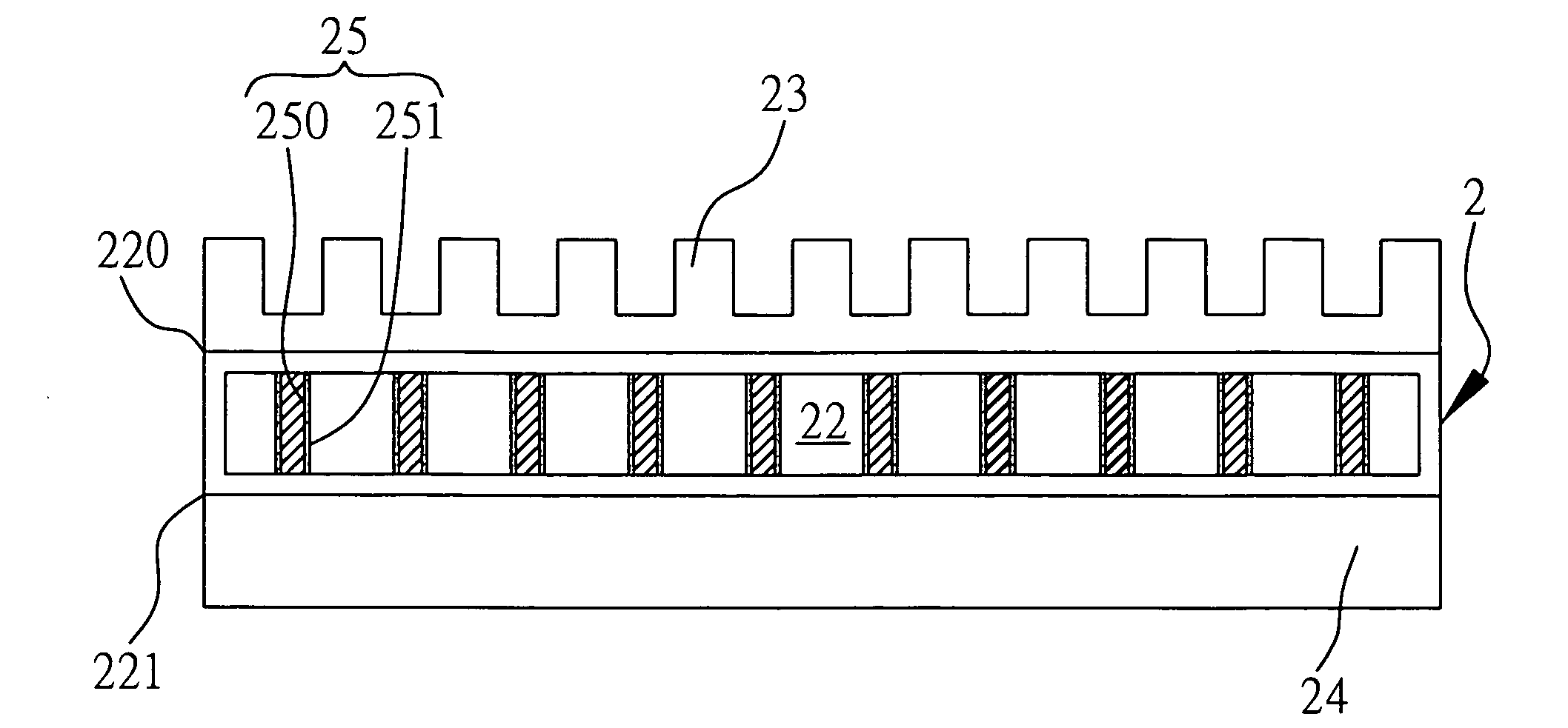

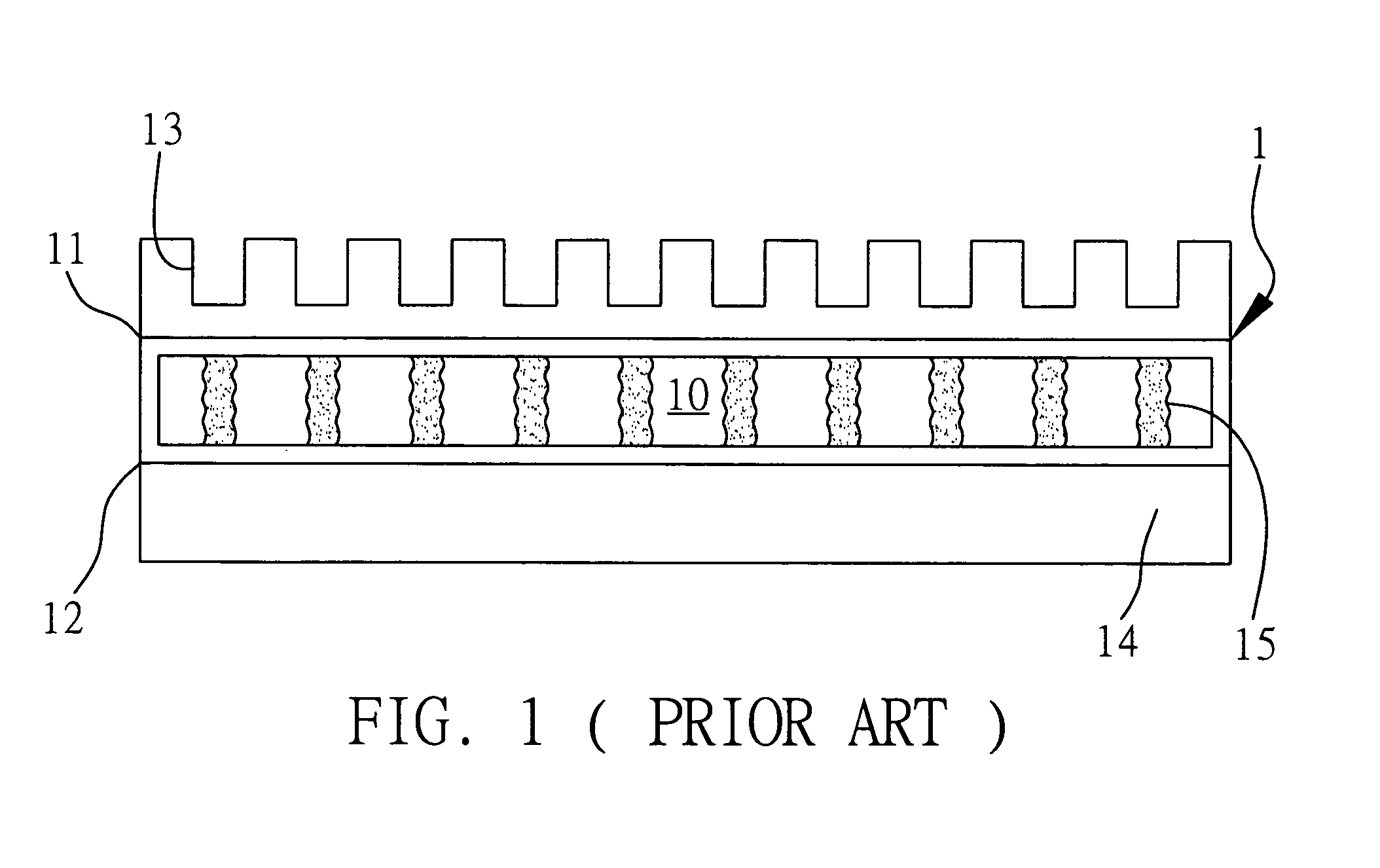

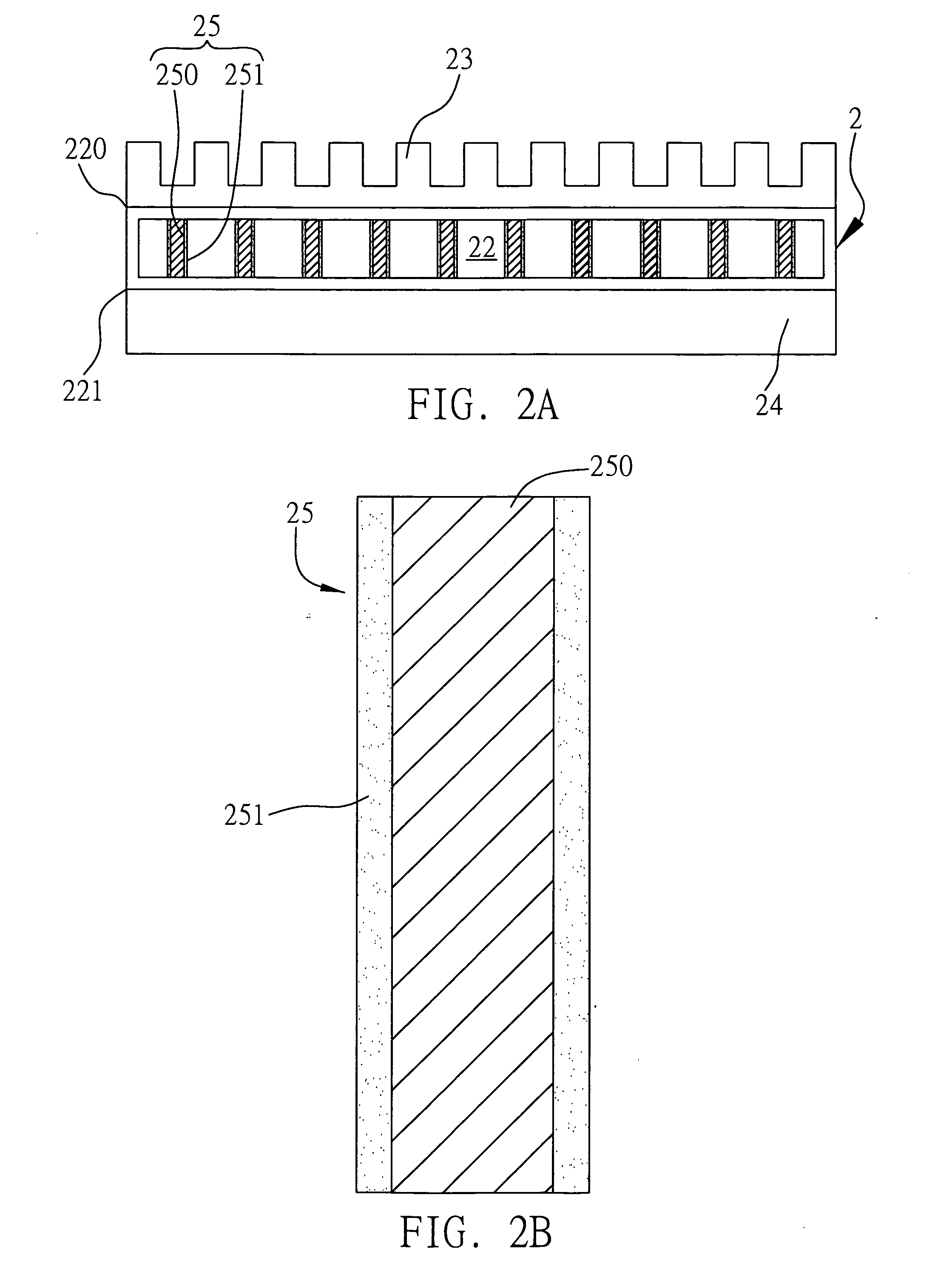

[0029]Referring to FIG. 2A, a cooler 2 comprises a chamber 22 including a condensation side 220 and an evaporation side 221. Disposed on the condensation side 220 is a cooling fin 23. In contact with the evaporation side 221 is a heat generating element 24 like a CPU. The chamber 22 is filled with working fluid of a low boiling point. The heat generating element 24 in operation generates heat, and thus the working fluid is heated up and evaporated into gas. Heat dissipation is carried out by means of the cooling fin 23 such that the gas is condensed into liquid. Accordingly, heat dissipation is achieved by phase cycling of the working fluid.

[0030]The present invention discloses a supporting column 25 having both a supporting body 250 and a porous structure 251. The supporting column 25 is disposed inside the chamber 22. Two ends of the supporting column 25 are connected to the evaporation side 221 and the condensation side 220. The porous structure 251 is formed ...

second embodiment

The Second Embodiment

[0031]FIG. 3 is a top plan view of the second embodiment of a supporting column of the present invention. This embodiment differs from the first embodiment in two ways. In this embodiment, a plurality of grooves 250a are formed on the supporting body 250, and cross sections of the grooves 250a are triangular in shape or in any processing friendly shape, for example, rectangular.

third embodiment

The Third Embodiment

[0032]FIG. 4 is an elevational view of the third embodiment of a supporting column of the present invention. This embodiment differs from the preceding embodiment in the way that the porous structure 251 comprises metal wire netting 252 so as to provide capillarity by tiny meshes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com