Fuel supply component purging system

a technology of fuel supply components and purging systems, which is applied in the direction of mechanical equipment, machines/engines, lighting and heating apparatus, etc., can solve the problems of affecting the ability of the particulate filter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

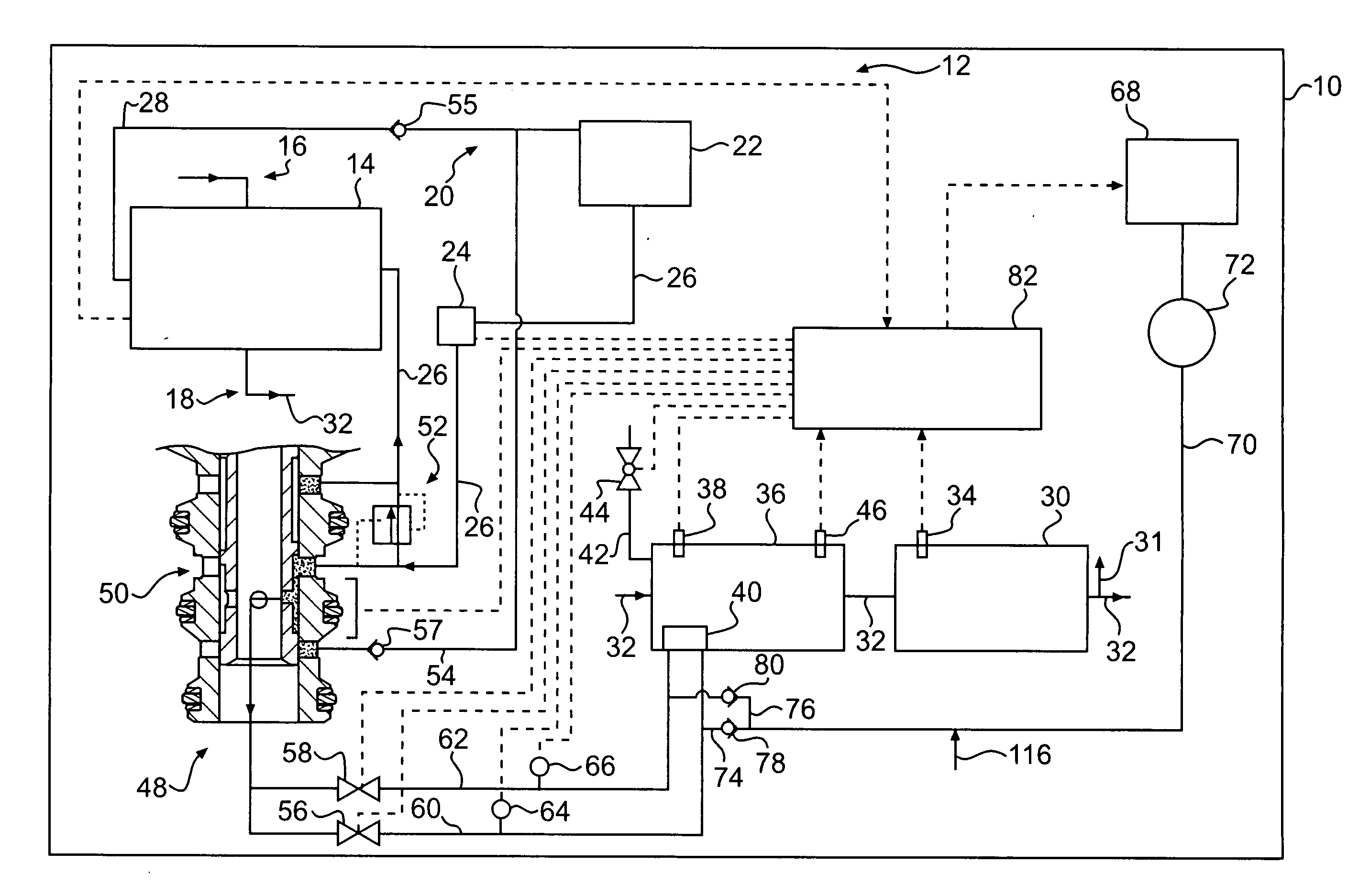

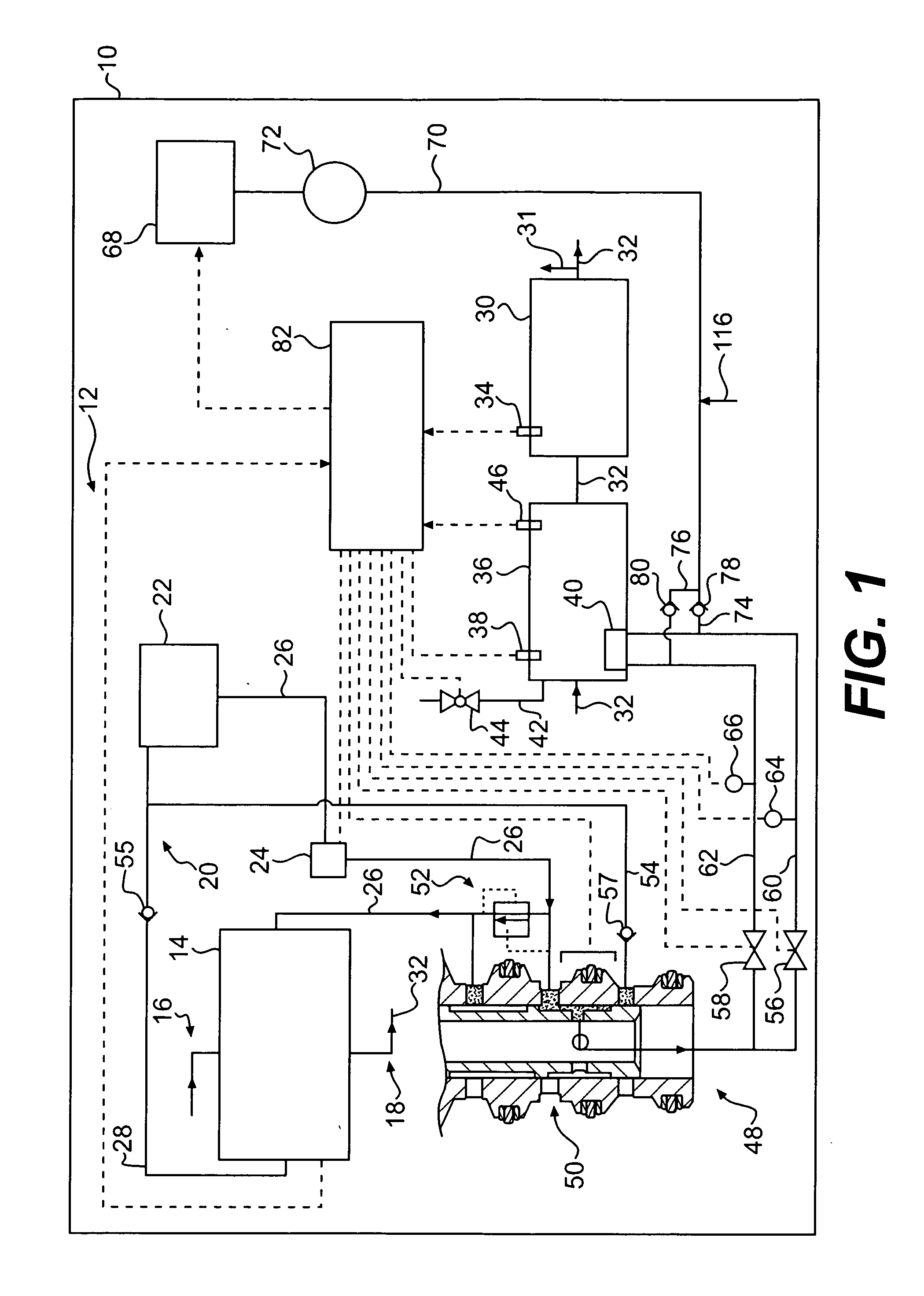

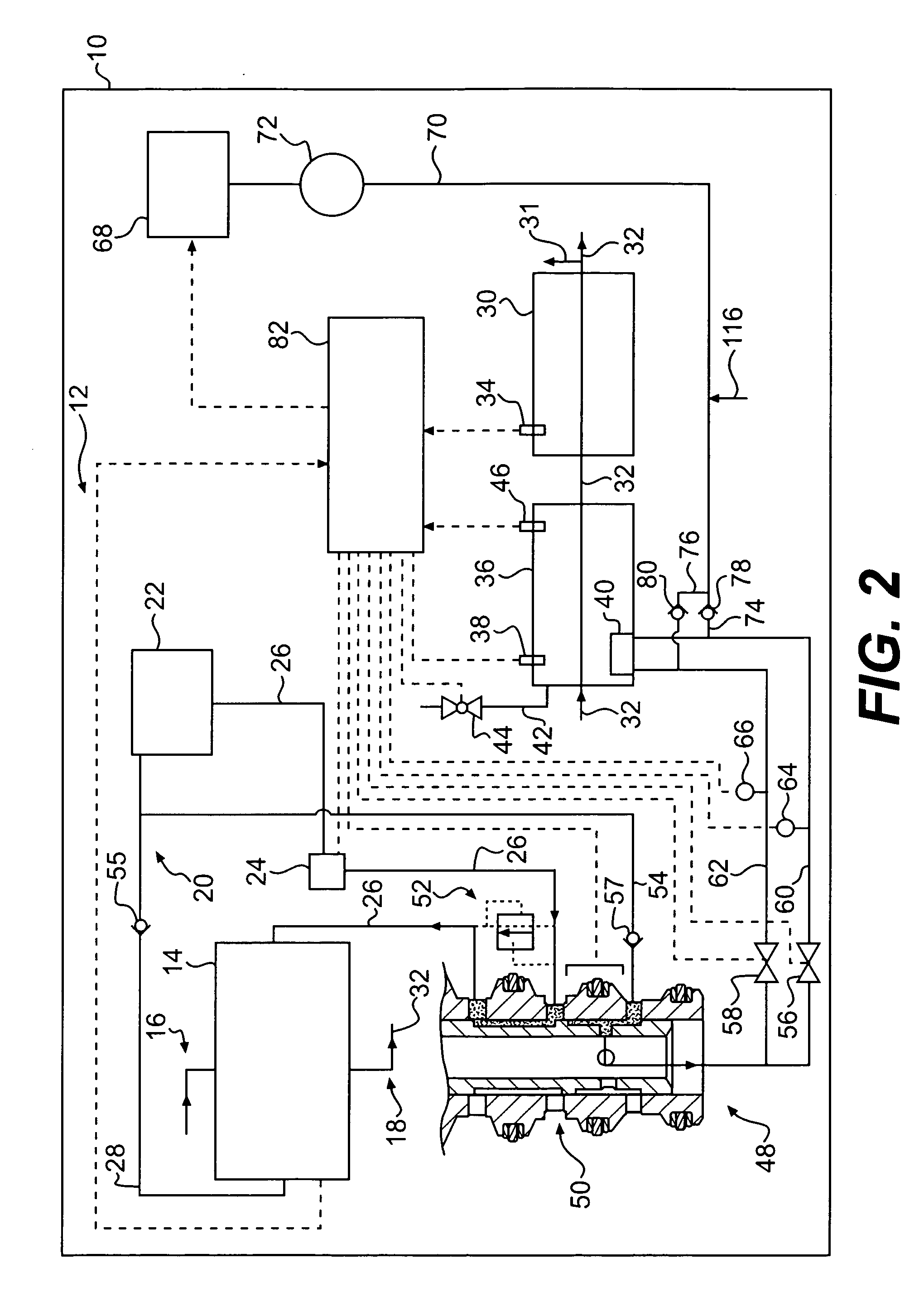

[0020]A machine 10, in which exemplary disclosed embodiments may be implemented, is diagrammatically represented in FIG. 1 and in FIG. 2. Machine 10 may be any of various machines, including an on-highway truck, an off-highway haulage unit, an excavating machine, a material handling machine, a stationary power generating machine, any of various heavy equipment machines, or any other machine which may benefit from implementation of embodiments according to the disclosure.

[0021]An engine system 12 may be associated with machine 10. Engine system 12 may include an engine 14 and various subsystems generally associated with an engine. Engine 14 may be any one of various types of engines, such as, a gasoline fueled engine, a diesel fueled engine, or a gas fueled engine. Engine 14 may require, among other things, an air intake system 16 and an exhaust system 18, both diagrammatically illustrated in FIG. 1. Air intake system 16 may include various unillustrated intake system components gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com