Solventless Extraction Process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

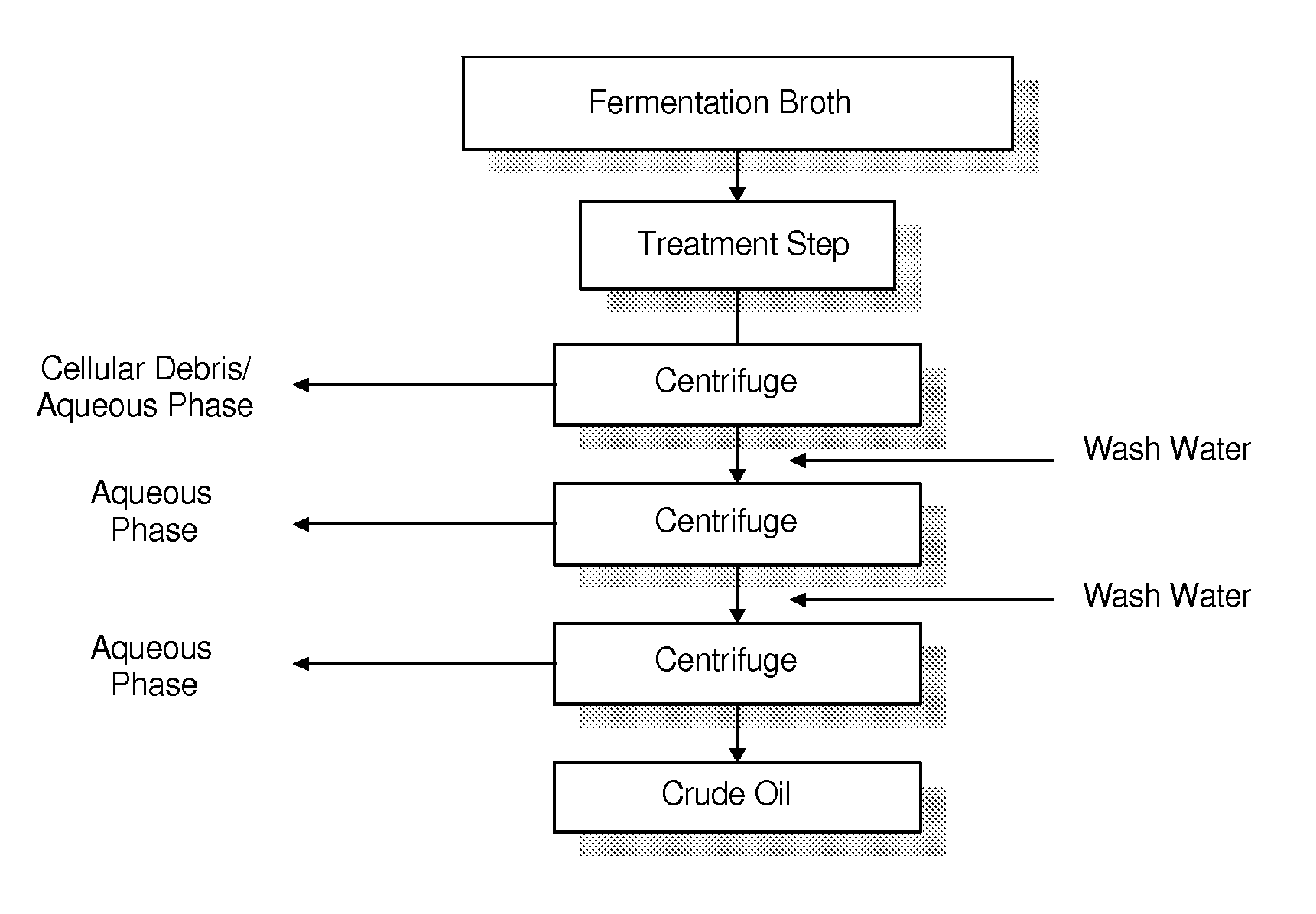

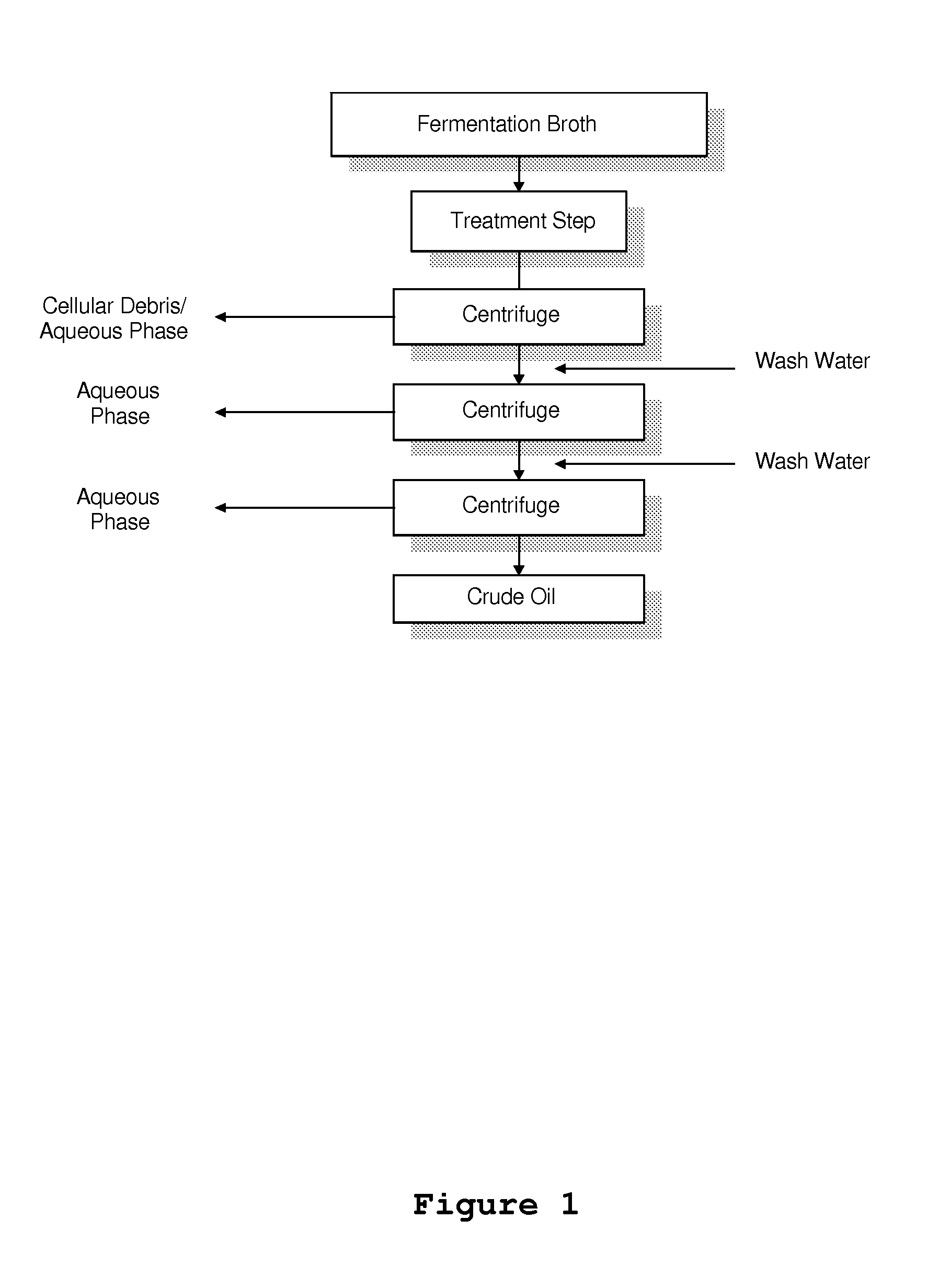

Image

Examples

examples

[0032] Process reproducibility was characterized by producing three samples of fully refined oil using crude oil from the new solventless extraction process. A hexane-extracted sample was also fully refined to serve as a control. The fermentation, extraction and oil isolation steps were performed at a large scale, while the oil refining studies were performed at a small scale.

[0033] The fully refined oil samples were analyzed to demonstrate process reproducibility.

[0034] A single F-Tank batch (˜1,200 gallons) was used to generate the starting broth for the three solventless extraction processes. The batch (#F99202) was allowed to run for 94 hours, while controlling the glucose levels at 13 g / L, after which time the corn syrup feed was terminated. Residual glucose levels dropped to <5 g / L four hours later. This resulted in a final age of 98 hours. The final broth volume was 958 gallons. The final yield was 146 g / L. Both in-process contamination checks and a thorough ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com