Excavator 3D integrated laser and radio positioning guidance system

a laser and navigation system technology, applied in vehicle position/course/altitude control, process and machine control, instruments, etc., can solve the problems of limited radio ranging or pseudolite machine control system, up to centimeter accuracy, etc., to improve the vertical accuracy of the mobile radio positioning system receiver, improve the accuracy of vertical accuracy, and improve the effect of accuracy

Inactive Publication Date: 2008-02-28

CATERPILLAR TRIMBLE CONTROL TECH

View PDF19 Cites 112 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

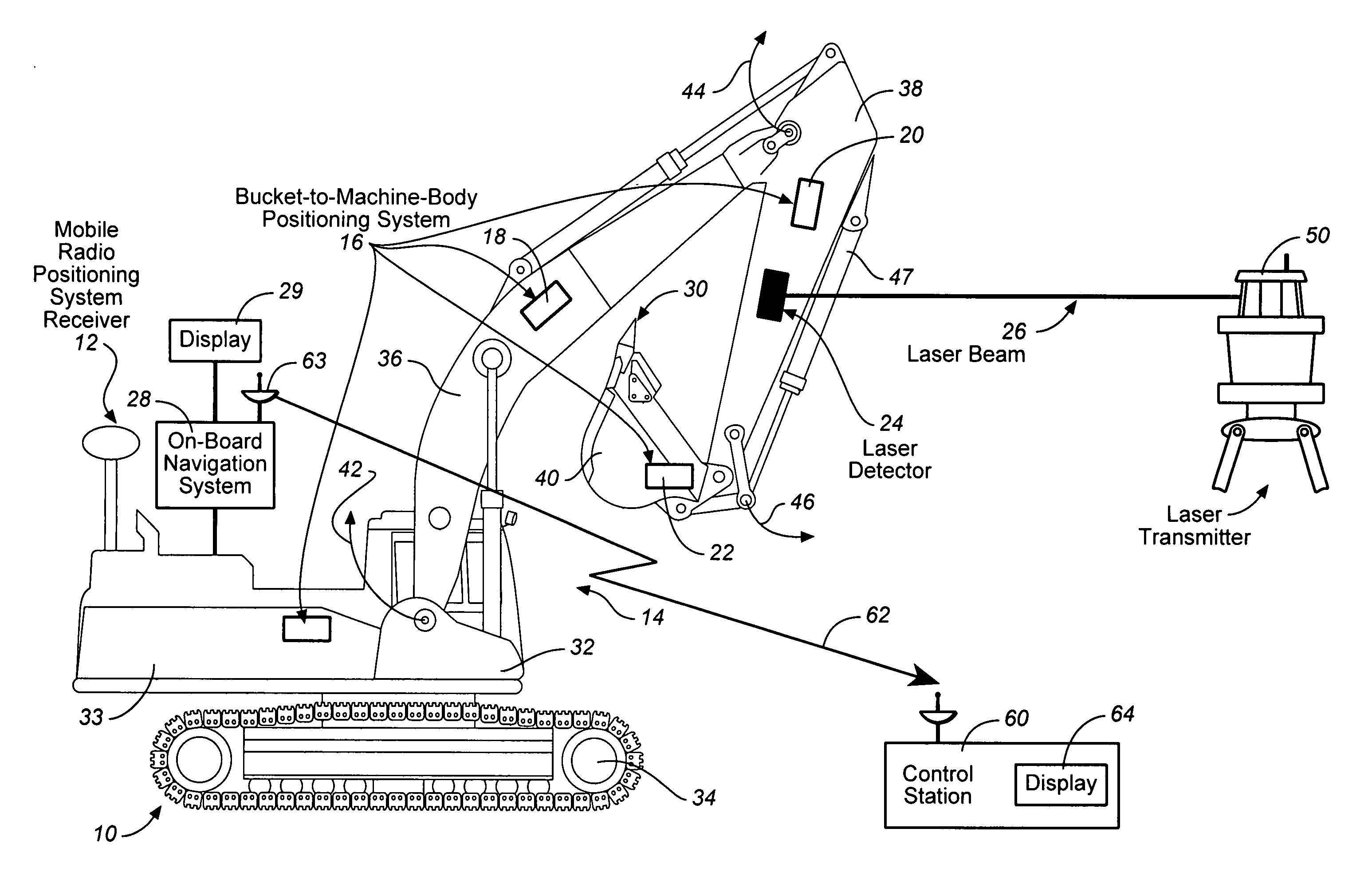

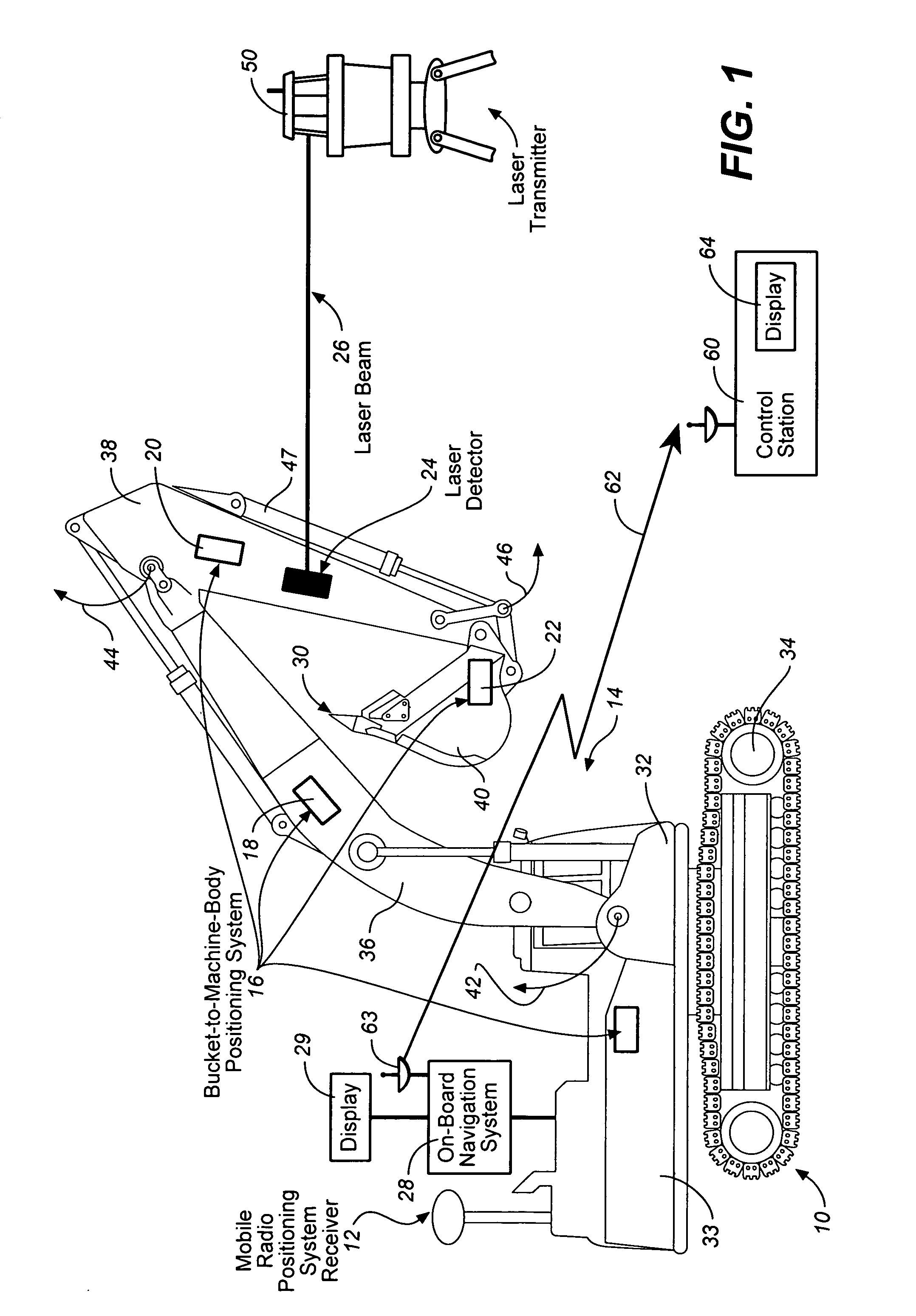

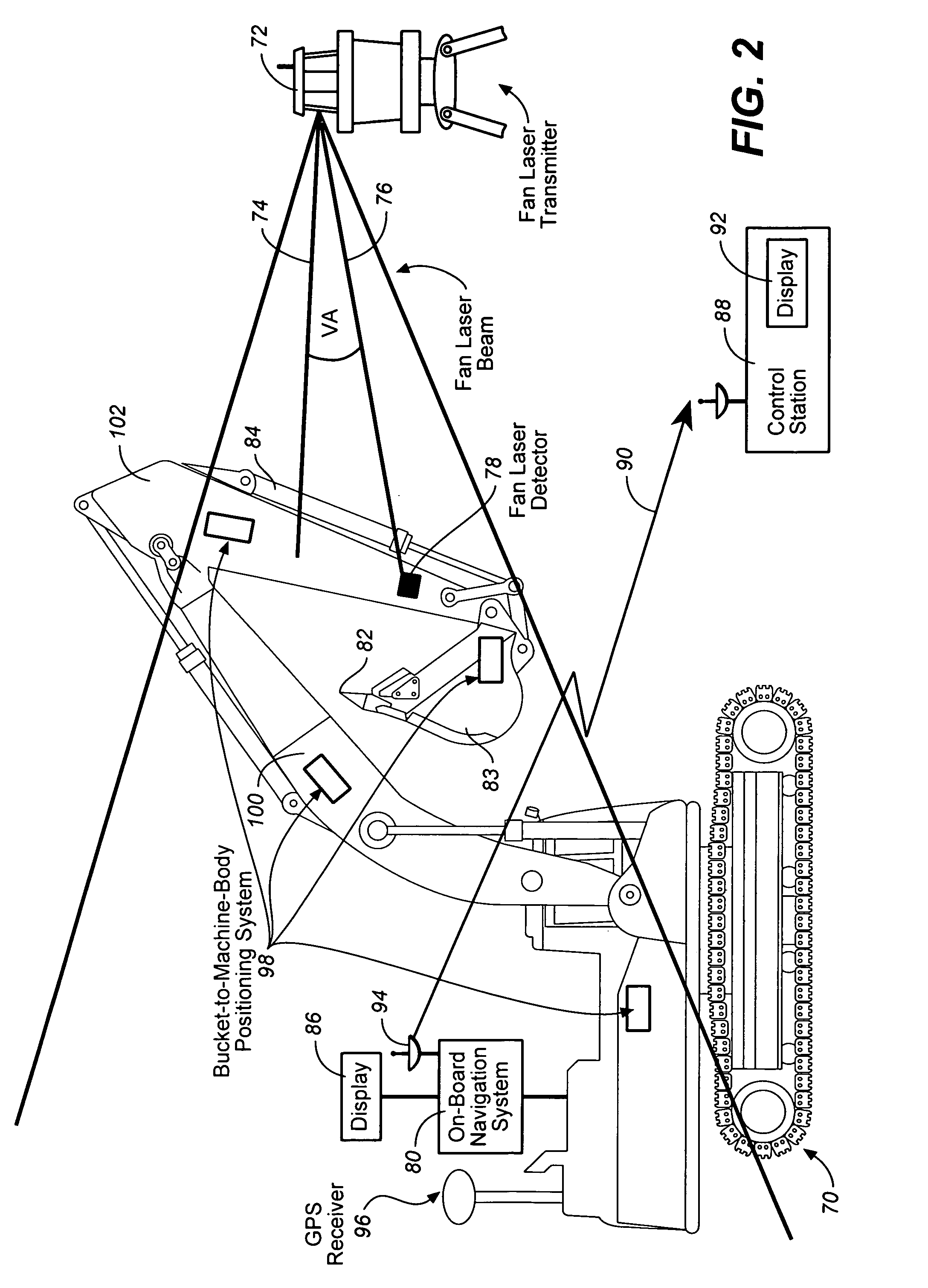

[0008]In one embodiment, the excavator 3D integrated laser and radio positioning guidance system (Ex—3D_ILRPGS) of the present invention comprises: a mobile radio positioning system receiver configured to obtain 2D horizontal coordinates of the excavator; a bucket-to-machine-body positioning system configured to determine the position coordinates of the boom, the stick and the bucket of the excavator relative to the machine body; a laser detector configured to receive at least one laser beam and configured to provide a local vertical coordinate with a substantially high accuracy; and an on-board navigational system configured to receive and to integrate the 2D horizontal coordinates of the excavator obtained by the mobile radio positioning system receiver, the position coordinates of the boom, the stick and the bucket of the excavator obtained by the bucket-to-machine-body positioning system, and the local vertical coordinate obtained by the laser detector, and configured to guide the cutting edge of the bucket of the excavator with substantially high vertical accuracy.

[0033]In one embodiment of the present invention, the method comprises: (A) obtaining a set of 3D coordinates measurements of the excavator by making a plurality measurements by using the mobile radio positioning system receiver; (B) obtaining position coordinates of the boom, the stick and the bucket of the excavator by utilizing the bucket-to-machine-body positioning system; (C) obtaining a set of local vertical coordinate measurements with a substantially high accuracy by making a plurality measurements by using the laser detector configured to receive at least one laser beam from a laser transmitter; (D) selecting a weight function configured to assign a 3D weight function to the set of 3D measurements obtained by using the mobile radio positioning system receiver, and configured to assign a vertical weight function to the set of local vertical coordinate measurements obtained by using the laser detector; (E) integrating the set of 3D coordinates measurements of the excavator with 3D weight function, and the set of the local vertical coordinate measurements with the vertical weight function by using the on-board navigational system in order to improve vertical accuracy of the mobile radio positioning system receiver; and (F) guiding the cutting edge of the bucket of the excavator with improved vertical accuracy by using the on-board navigational system.

Problems solved by technology

However, the radio ranging or pseudolite machine control systems have limited, up to centimeter accuracy.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

examples

[0115]1) Benching on a point of known height and then catching the beam to get a known height on the beam for both flat surface and sloping surfaces.

[0116]2) Stopping in the beam and averaging a number of GPS positions with reference to the beam to get an elevation on the beam (or elevation and orientation on a sloping beam)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

An excavator 3D integrated laser and radio positioning guidance system (Ex_3D_ILRPGS) comprising: a mobile radio positioning system receiver configured to obtain 2D horizontal coordinates of the excavator, a bucket-to-machine-body positioning system configured to obtain coordinates of the boom, the stick and the bucket of the excavator, a laser detector configured to receive at least one laser beam and configured to provide a local vertical coordinate with a substantially high accuracy, and an on-board navigational system configured to receive and to integrate the 2D horizontal coordinates of the excavator obtained by the mobile radio positioning system receiver, the coordinates of the boom, the stick and the bucket of the excavator obtained by the bucket-to-machine-body positioning system, and the local vertical coordinate obtained by the laser detector, and configured to guide the cutting edge of the bucket of the excavator with substantially high vertical accuracy.

Description

TECHNICAL FIELD[0001]The current invention relates to position tracking and machine control systems, and, more specifically, to a combination of laser systems and radio positioning systems configured to complement each other in order to optimize the tracking and machine control capabilities of prior art systems.BACKGROUND ART[0002]In recent times there have been advances in the area of radio ranging or pseudolite machine control systems. However, the radio ranging or pseudolite machine control systems have limited, up to centimeter accuracy.[0003]For example, Trimble introduced a family of machine control systems including the GCS300 with a single elevation control, the GCS400 having a dual elevation control, the GCS500 with a cross slope control, the GCS600 having a cross slope and elevation control, and finally, the GCS900 that provides a full 3D control up to centimeter accuracy. In another example, Trimble also introduced the SiteVision HEX machine control systems. Trimble's ver...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E02F5/02G01S5/14

CPCE02F3/435G01S1/70G01S19/10G08C21/00G01S19/45G01S19/51G01S19/14E02F9/264

Inventor NICHOLS, MARK E.

Owner CATERPILLAR TRIMBLE CONTROL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com