Information Processing System for Producing Building Material, Building Material Production Method and Production Equipment, and Building Information Distribution System

a technology for information processing and building materials, applied in computer control, program control, instruments, etc., can solve the problems of reducing production efficiency, large space required for installation of production lines, and building costs, so as to improve production efficiency, reduce production efficiency, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Exemplary embodiments of the invention are explained below with reference to the drawings.

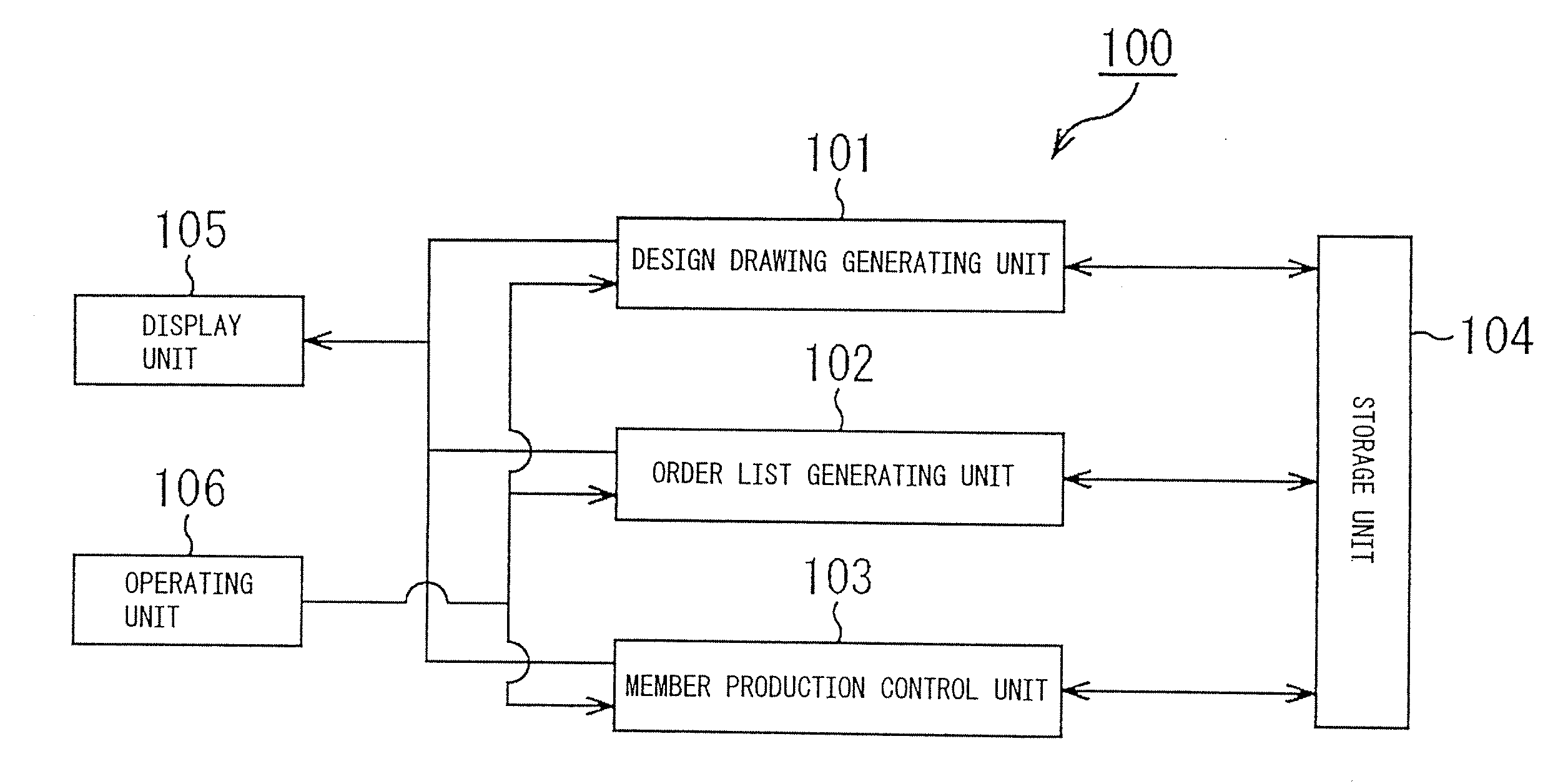

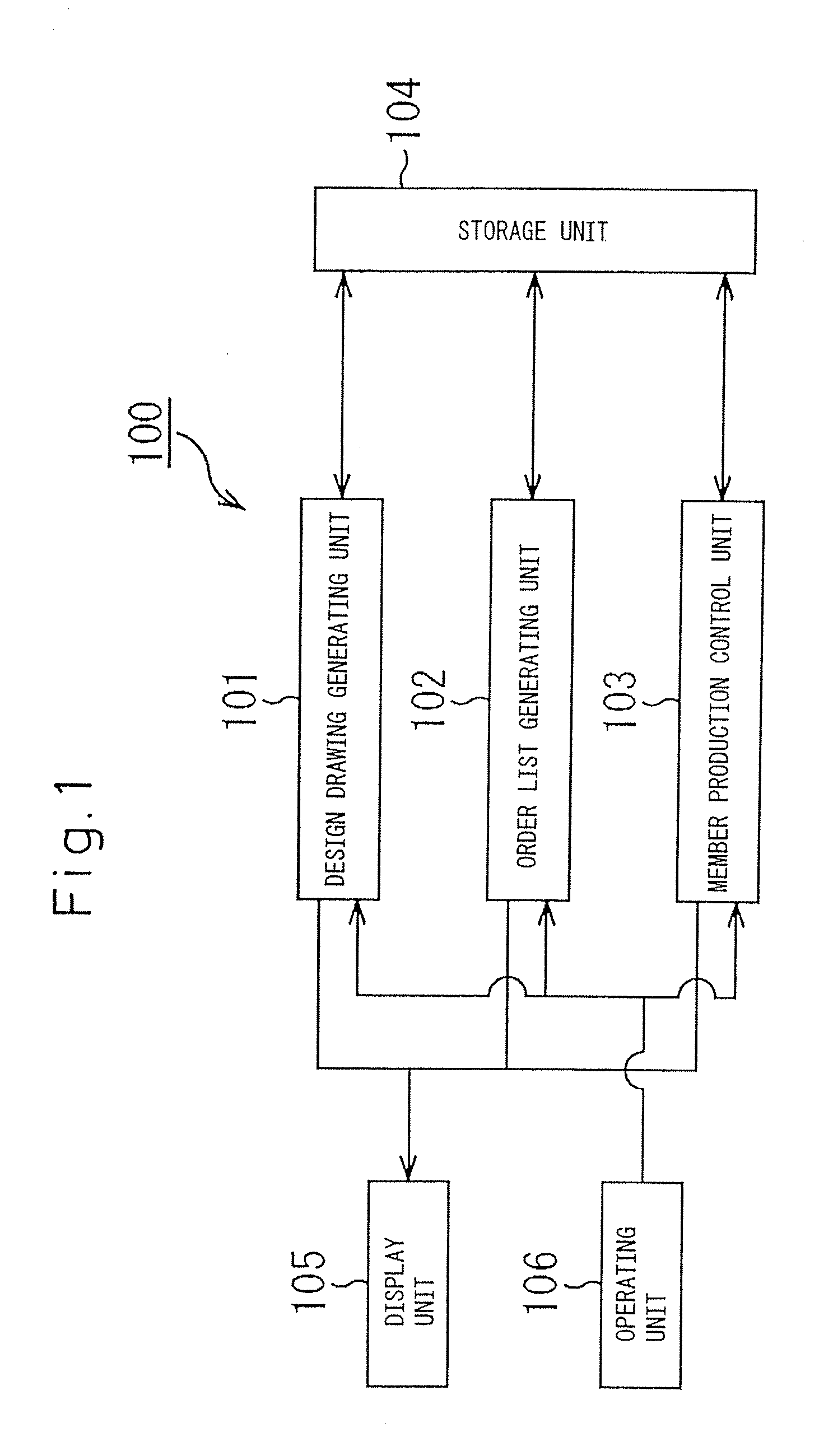

[0066] Referring to FIG. 1, an information processing system 100 according to an exemplary embodiment of the present invention can be used for efficiently producing the light gauge shape sheet steel for a steel house, and comprises a design drawing generating unit 101, an order list generating unit 102, a member production control unit 103, a storage unit 104, a display unit 105 and an operating unit 106.

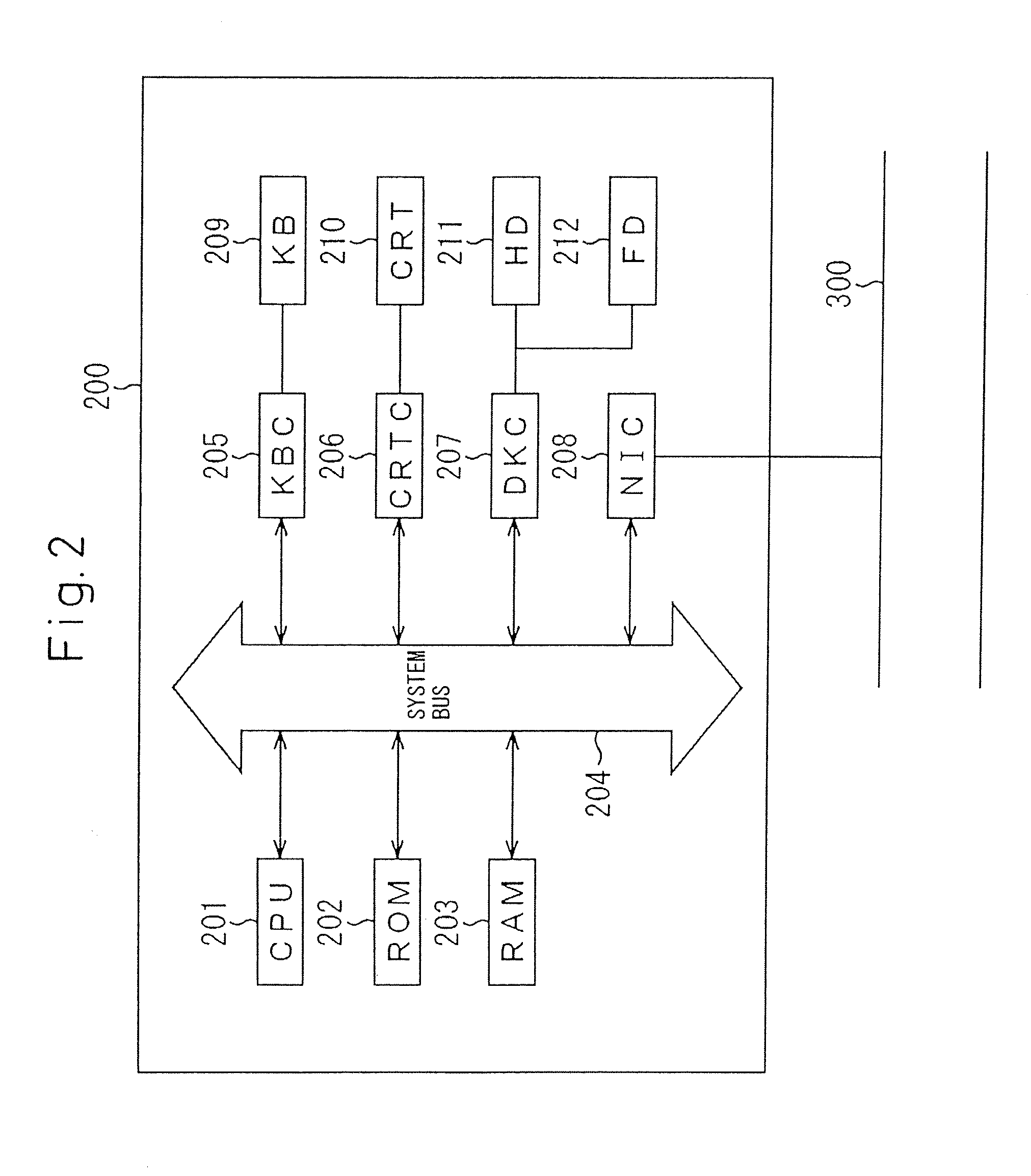

[0067]FIG. 2 shows a block diagram of a hardware configuration of the information processing system 100, the information processing system 100 can be implemented by, for example, a computer 200.

[0068] The computer 200, as shown in FIG. 2, comprises a CPU 201, a ROM 202, a RAM 203, a keyboard controller (KBC) 205 of a keyboard (KB) 209, a CRT controller (CRTC) 206 of a CRT display (CRT) 210, a disk controller (DKC) 207 for a hard disk (HD) 211 and a flexible disk (FD) 212, and a networ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| workability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com