Process for plating plastic part after overmolding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

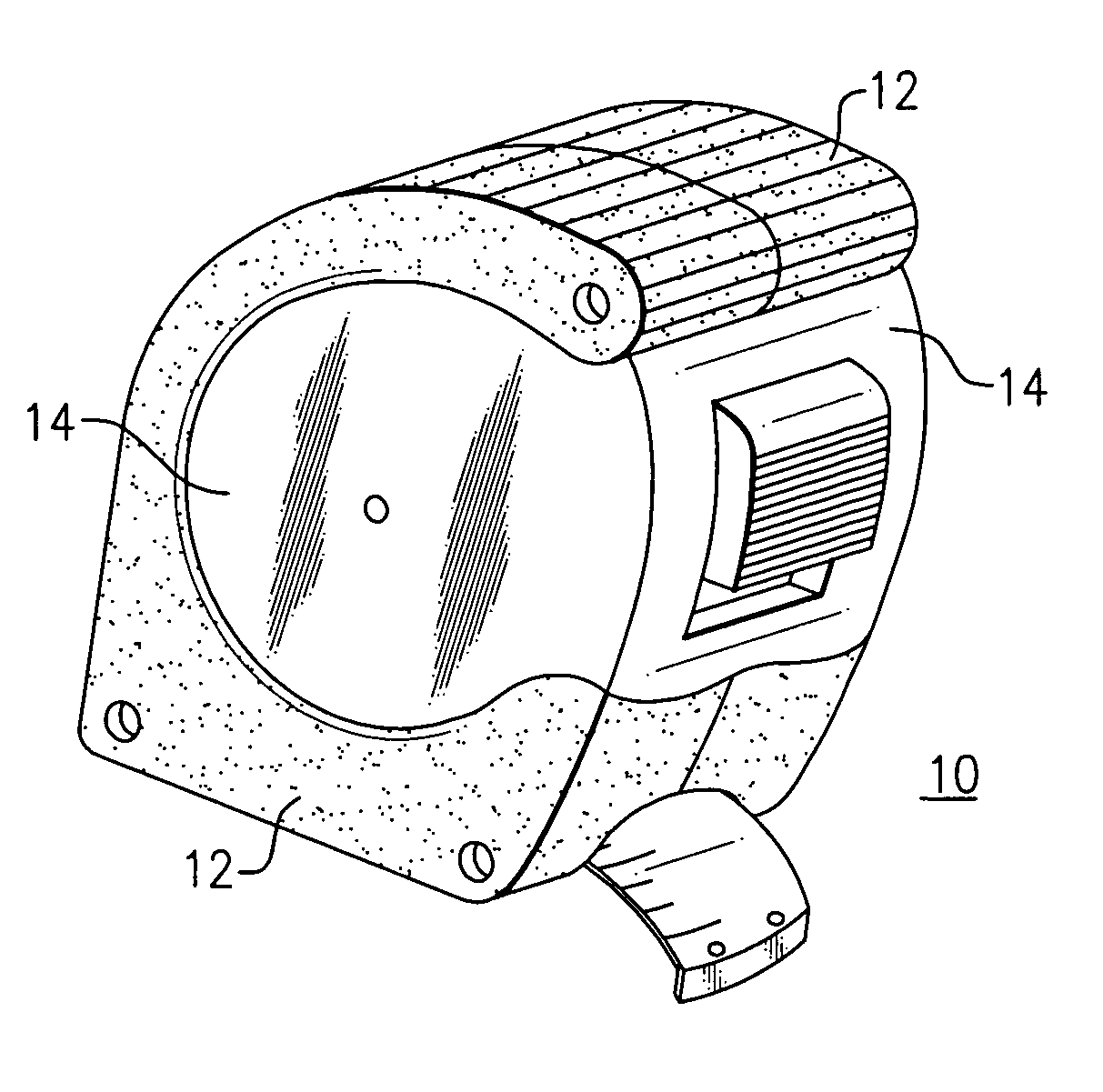

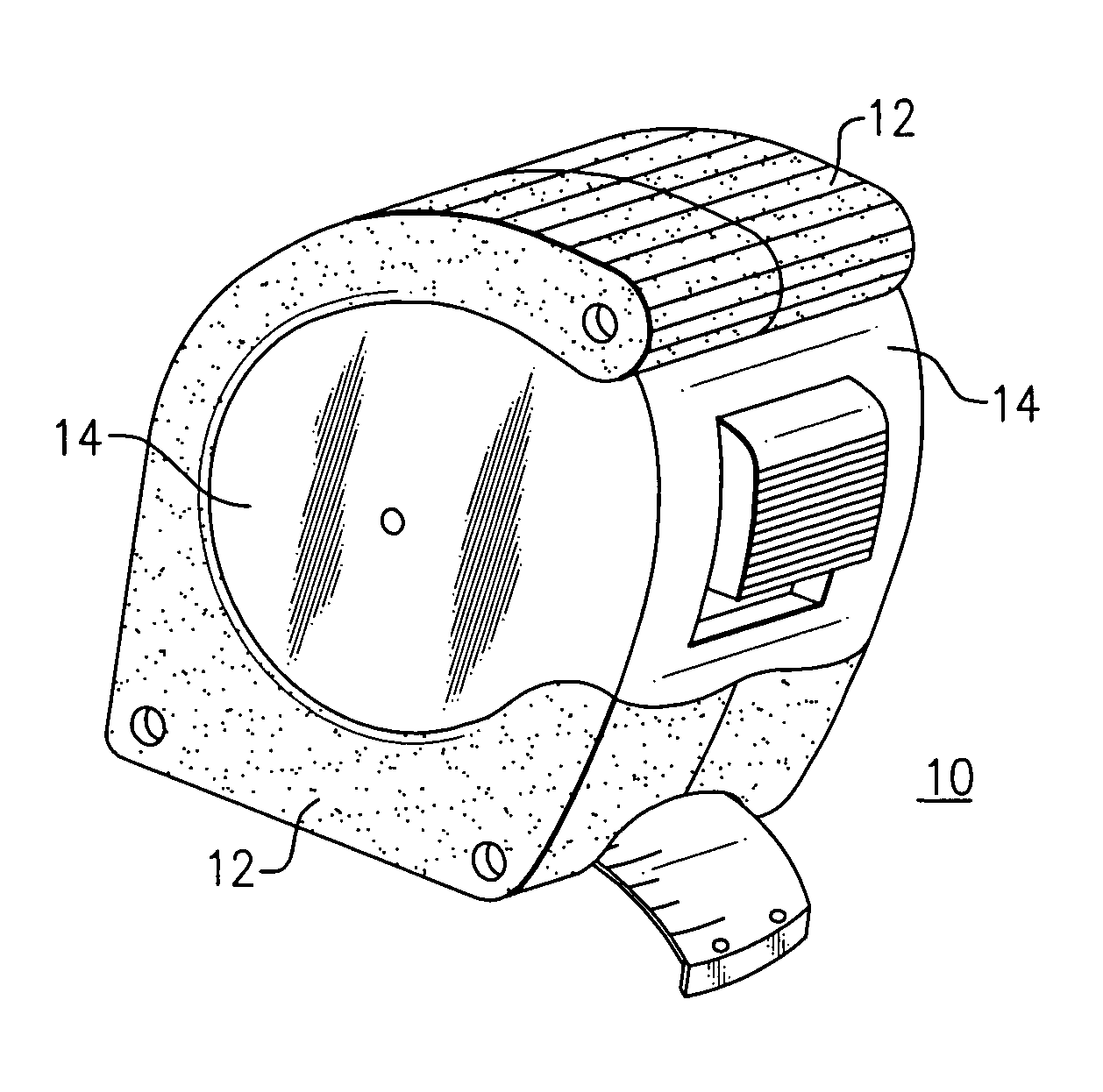

[0015]The FIGURE shows an example of a plastic molded item, namely a case 10 for a tape rule, which is formed of a rigid plastic material, e.g., ABS or polystyrene or polycarbonate, with overmolded grip portions 12 formed of a suitable TPE, which in this embodiment is Empilon PHA 61B. Here the case is fabricated as left and right halves, i.e., a cover half and a hub half, and each of these is subjected to metallization of exposed surfaces 14, i.e., those not occupied by the grip portions 12.

[0016]As discussed before, the tape rule case is but one example, and the technique can be used for many other tools and implements or other products where a rubbery grip may be desired.

[0017]The rigid plastic right and left halves of the case are first formed by a traditional plastic molding technique. In one example, the case substrate is molded of ABS. Then each housing half is provided with the overmolded grip portions, applying the Empilon TPE material. Favorably, one possible TPE has the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Digital information | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Plasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com