Partially prefabricated modular foundation system

a modular foundation and prefabricated technology, applied in the field of partially prefabricated foundations, can solve the problems of compromising the structural integrity of the foundation, the risk of thermal cracking becomes very high, etc., and achieves the effects of reducing engineering work, reducing engineering work, and simplifying the permitting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

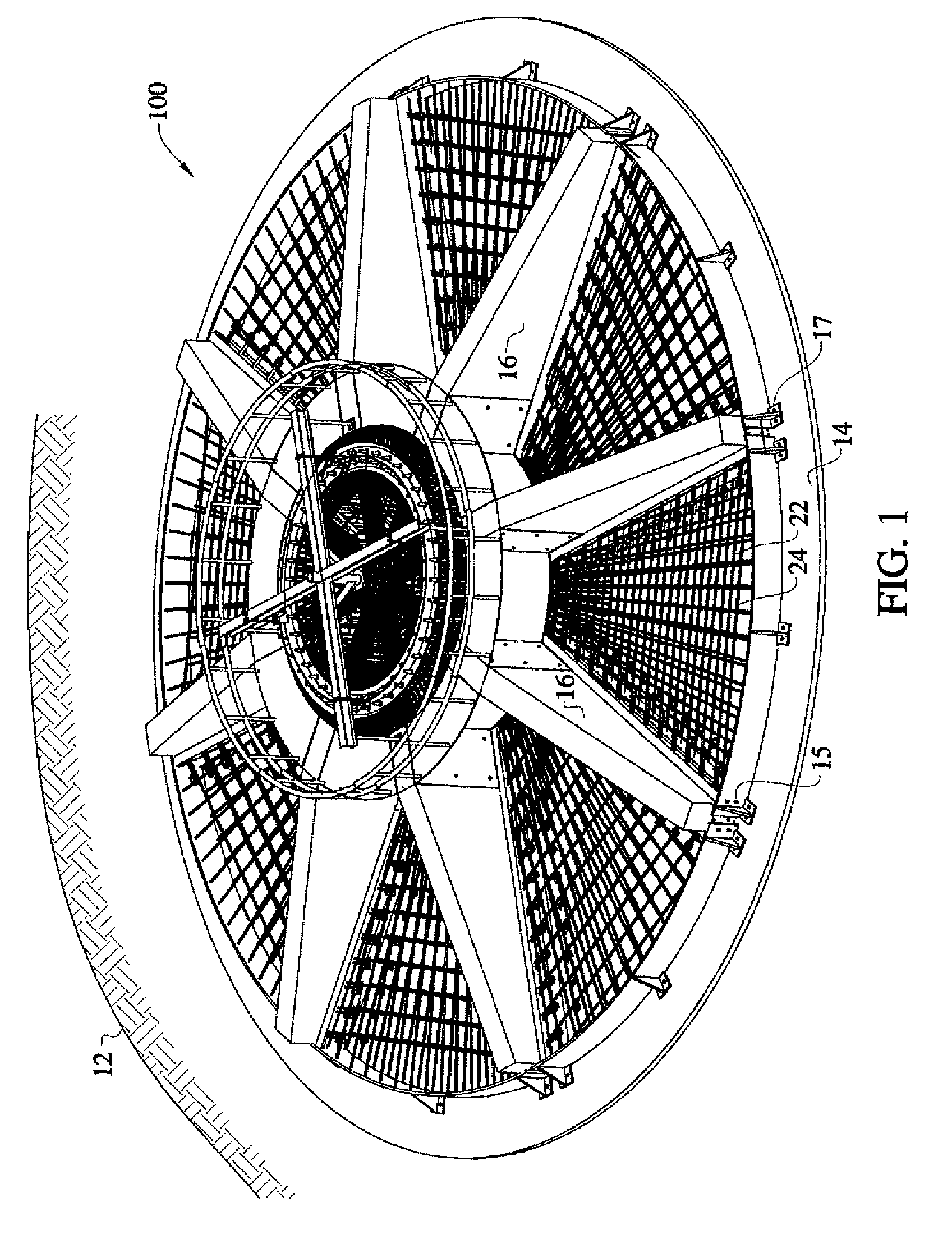

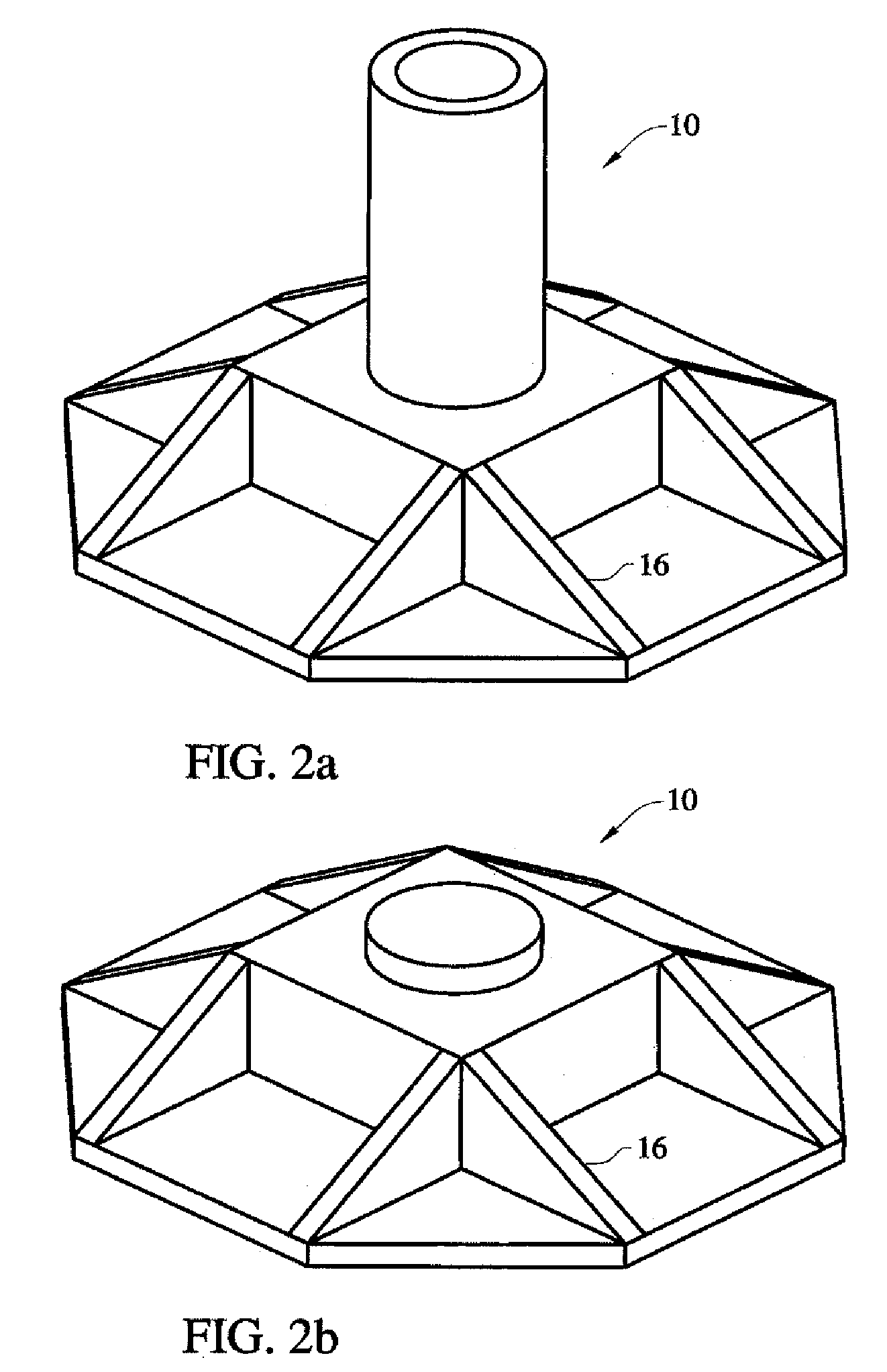

[0063]The present invention pertains to a wind turbine foundation for wind turbines. The foundation comprises a plurality of components, namely a central vertical pedestal, a substantially horizontal bottom support slab, and a plurality of radial reinforcing ribs extending radially outwardly from the pedestal. The ribs are prefabricated and transported to job site, but the pedestal and support slab are poured in situ at the site out of concrete.

[0064]A construction site is prepared by excavation and flattening and preparation of soil for the foundation 10. The foundation 10 may be set on pilings, on piers, or have anchors in a conventional manner.

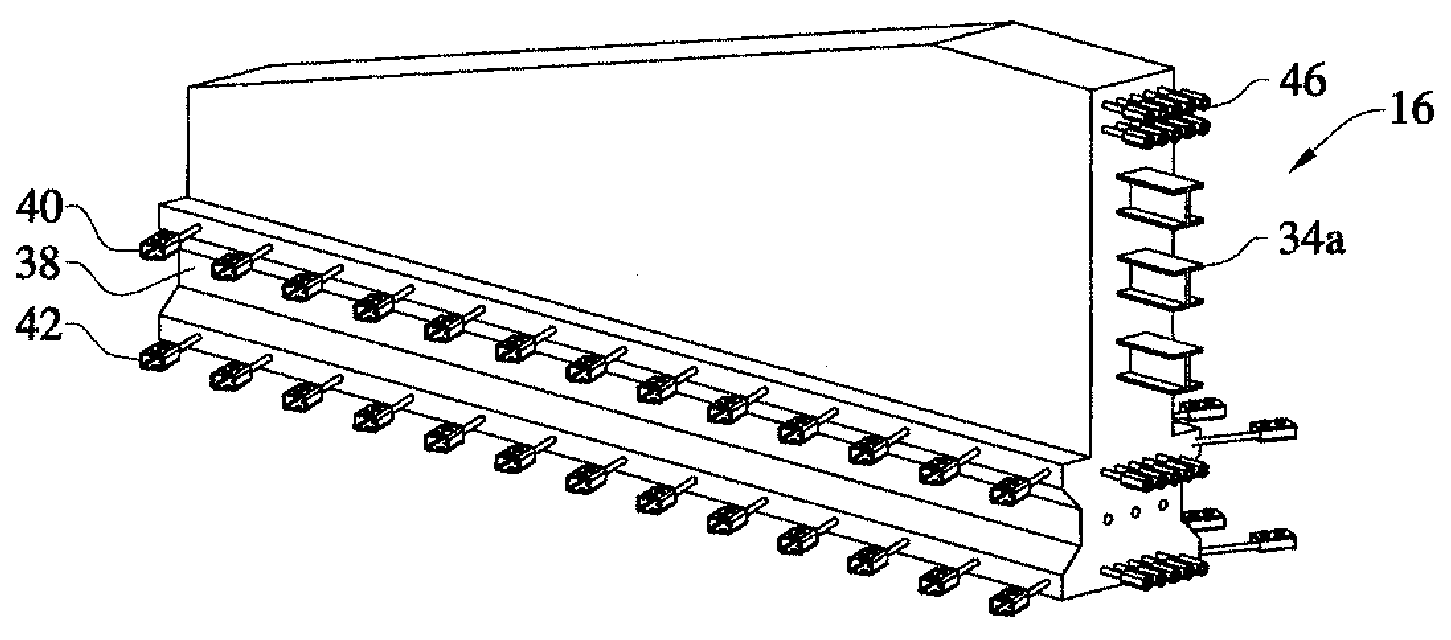

[0065]The foundation 10 may be set on a mud slab 14 or on compacted granular fill. The mud slab is often a thin plain concrete layer intended to provide a clean and level base for foundation installation. After the foundation site has been prepared, a plurality of three or more precast stiffener ribs 16 are placed on the mud slab 14 or comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com