Carbon fuel combustion supporting packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

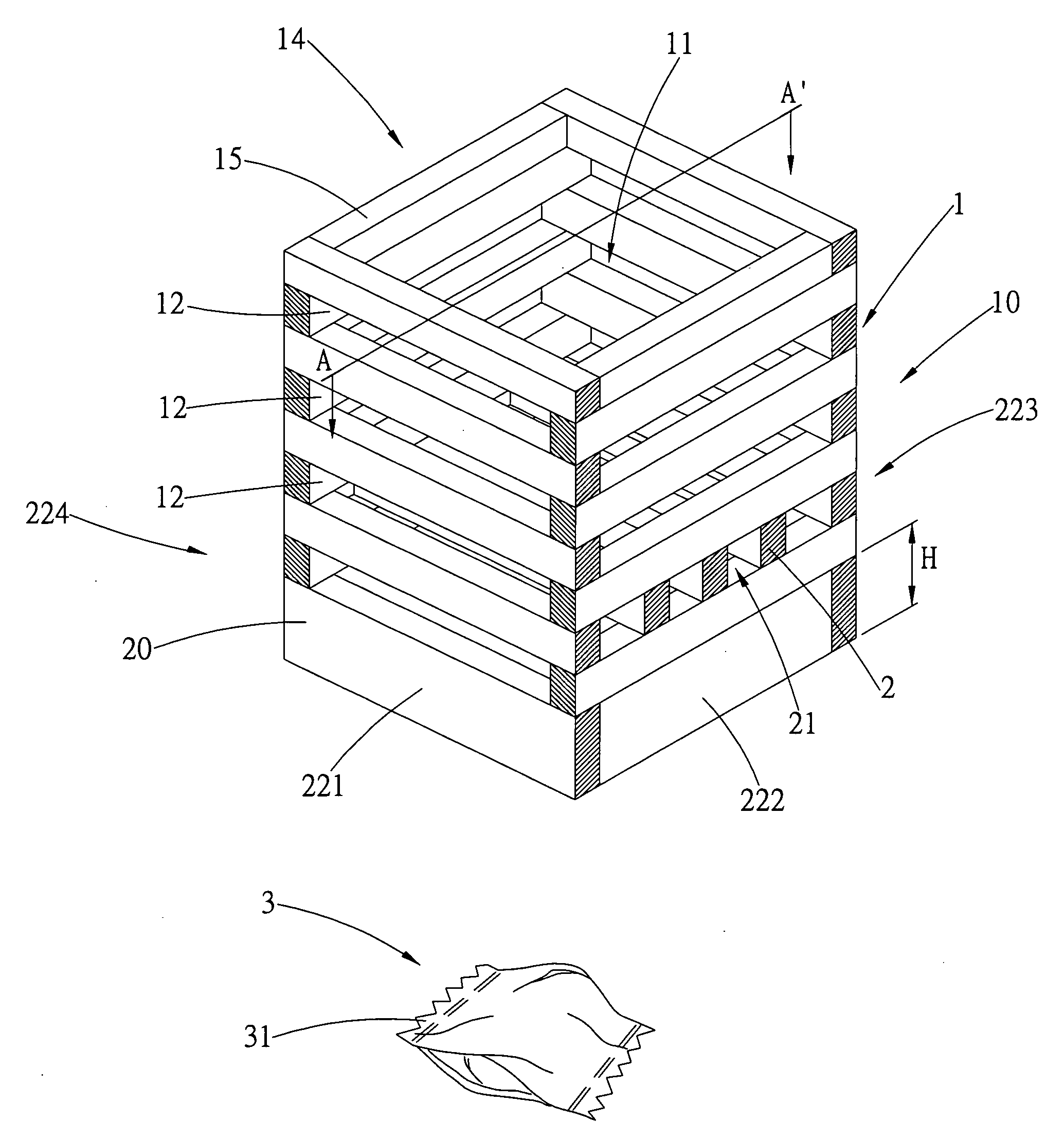

[0032]Referring to FIG. 4, which shows a three-dimensional schematic view of the present invention, comprising a packing body 10 primarily structured from a bottom frame 20 joined to an enclosing body 1. The packing body 10 comprising the combustible bottom frame 20, a periphery of which comprises enclosing boards 221, 222, 223, 224, which are structured as an enclosure to form lateral windbreaks, and an upper end opening is upwardly separately by combustible grid-type fire grates 2. An upper end of the bottom frame 20 is joined to the combustible enclosing body 1, and the combustible enclosing body 1 is formed by interlocking a plurality of combustible rod members 15, thereby forming a plurality of through holes 12 in the periphery of the enclosing body 1.

[0033]The enclosing body 1 located on the upper end of the bottom frame 20 shapes a holding space 11, and the bottom frame 20 forms a raised space H which enables a kindling 3 to be disposed therein.

[0034]The grid-type fire grates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com