Method and apparatus for production of high-pressure nitrogen from air by cryogenic distillation

a technology of cryogenic distillation and air, which is applied in the direction of lighting and heating apparatus, refrigeration and liquid storage, solidification, etc., can solve the problems that simple two-column system does not necessarily have lower unit energy requirements and nitrogen recovery, and achieves high nitrogen recovery, low unit energy consumption, and high nitrogen recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

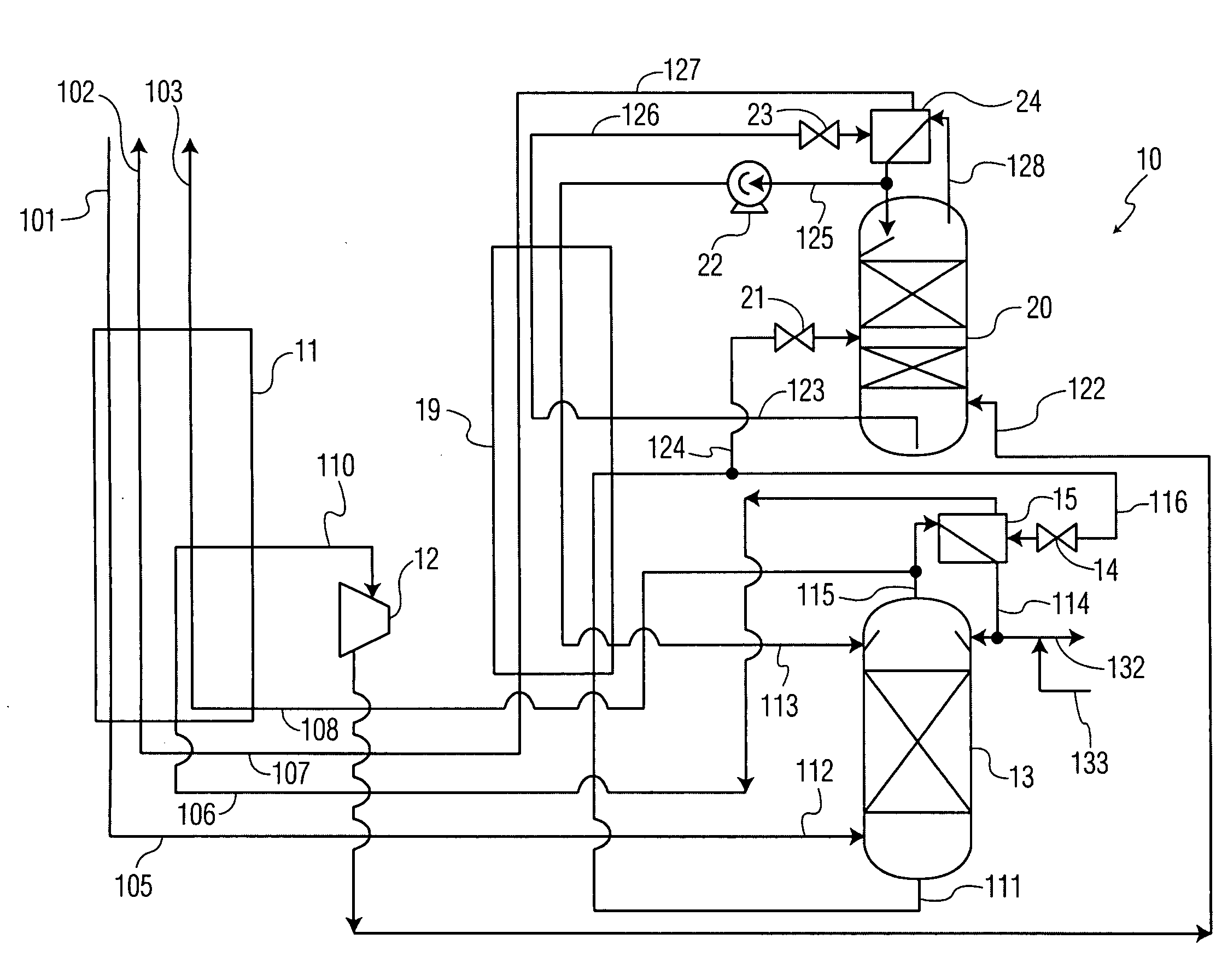

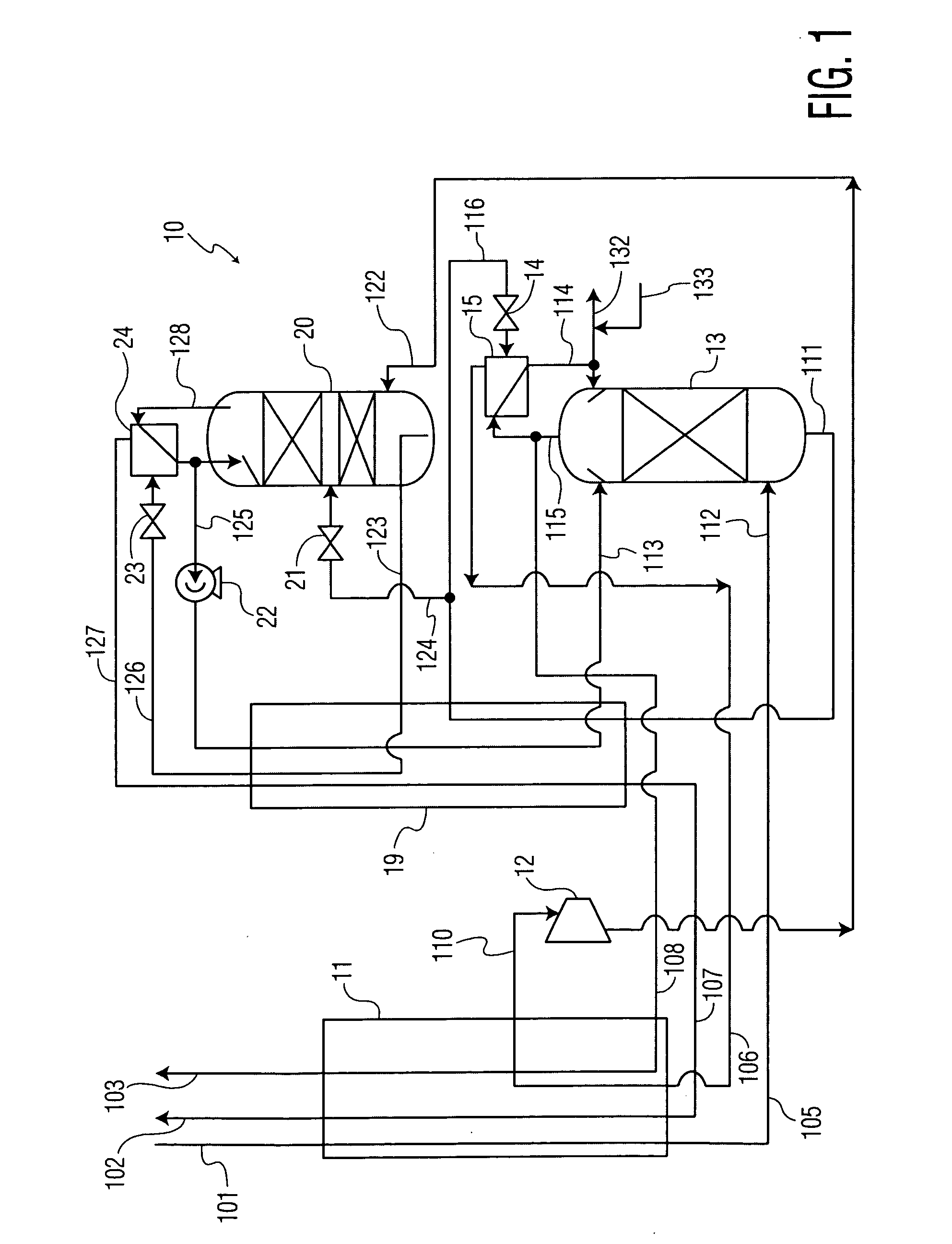

[0025]A process for the recovery of substantially pure nitrogen at a rate of 1493 kg moles / hr at a pressure of 11.35 bar(a) is conducted in accordance with FIG. 1. kg moles / hr refers to the flow rate in kilogram moles per hour. ° C. refers to temperature in degrees Celsius; bar(a) refers to absolute pressure in bars. In the specification, psia refers to pounds per square inch absolute.

[0026]A feed air flow of 2408 kg moles / hr was compressed, aftercooled to about ambient temperature, its water condensate removed, and passed to an adsorption unit for removal of water and carbon dioxide, and possibly other contaminants. The purified air 101 at 11.96 bar(a) was passed to main heat exchanger 11 where it was cooled to approximately its dew point. Air 105 entered the bottom of high pressure column 13 at −162.0° C. and 11.89 bar(a). The high pressure column is internally made up of distillation trays or structured packing for mass transfer.

[0027]Gaseous nitrogen 115 at −167.3° C. and 11.42 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com