Method for preparing low-bitterness whey protein antioxidative peptide powder

A technology of whey protein and anti-oxidation, applied in fermentation and other directions, can solve the problems of adding desalination process, etc., and achieve the effect of good sensory, small molecular weight and low molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

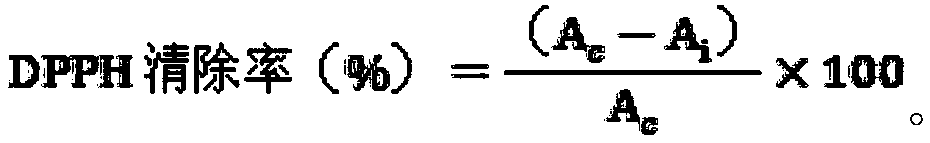

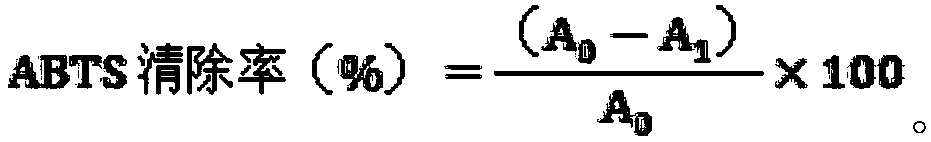

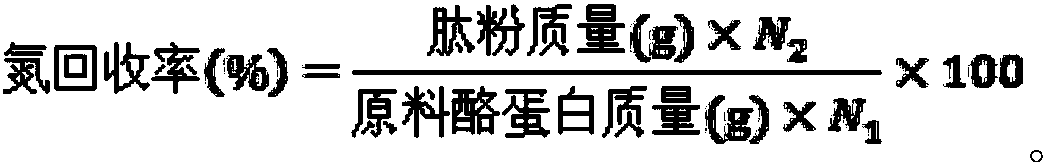

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing low-bitter whey protein antioxidant peptide powder, the specific content is as follows:

[0048] (1) Protease enzymatic hydrolysis: take a whey protein aqueous solution with a mass fraction of 5%, stir at 90°C for 10 minutes to dissolve the whey protein, put it in a magnetic thermostatic enzyme reactor, add neutral protease, and The mass ratio of protease to whey protein is 2:100, and the constant temperature enzymatic hydrolysis is 3.5h. After the first enzymatic hydrolysis, the enzyme will not be extinguished. Continue to add ProteAX protease. The mass ratio of ProteAX protease to whey protein is 1.5:100. The hydrolysis was carried out for 3.5 hours, and after the two enzymatic hydrolysis, the enzyme was boiled at 95°C for 10 minutes to obtain the whey protein enzymatic hydrolysis solution.

[0049] (2) Preparation of peptide powder: After the enzymatic solution was centrifuged at 7000r / min for 15min, the supernatant was collected as a crude pep...

Embodiment 2

[0051] A method for preparing low-bitter whey protein antioxidant peptide powder, the specific content is as follows:

[0052] (1) Protease enzymatic hydrolysis: take a whey protein aqueous solution with a mass fraction of 2%, stir at 90°C for 10 minutes to dissolve the whey protein, and when the temperature is lowered to 55°C, place it in a magnetic constant temperature enzyme reactor, add neutral protease, and The mass ratio of protease to whey protein is 0.5:100, and the enzyme is hydrolyzed at constant temperature for 3 hours. 3h, after the two enzymatic hydrolysis, the enzyme was boiled at 95°C for 10min to obtain the whey protein enzymatic hydrolyzate.

[0053] (2) Preparation of peptide powder: After the enzymatic solution was centrifuged at 7000r / min for 15min, the supernatant was collected as a crude peptide solution, and the crude peptide solution was passed through an ultrafiltration membrane with a cut-off of 10kDa at a pressure of 0.5MPa to remove lipids , macrom...

Embodiment 3

[0055] A method for preparing low-bitter whey protein antioxidant peptide powder, the specific content is as follows:

[0056] (1) Protease hydrolysis: Take whey protein aqueous solution with a mass fraction of 5%, stir at 90°C for 10 minutes to dissolve the whey protein, put it in a magnetic thermostatic enzyme reactor, add neutral protease, and The mass ratio of protease to whey protein is 1.5:100, and the enzyme is hydrolyzed at constant temperature for 4 hours. After the first enzymolysis, the enzyme is not extinguished, and ProteAX protease is added. The mass ratio of ProteAX protease to whey protein is 1:100, and the enzyme is hydrolyzed at constant temperature. 3h, after the two enzymatic hydrolysis, the enzyme was boiled at 95°C for 10min to obtain the whey protein enzymatic hydrolyzate.

[0057] (2) Preparation of peptide powder: After the enzymatic solution was centrifuged at 7000r / min for 15min, the supernatant was collected as a crude peptide solution, and the crud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com