Discharge cell for ozonizer

a technology of ozonizer and discharge cell, which is applied in the direction of electrical discharge ozone preparation, oxygen/ozone/oxide/hydroxide, etc., can solve the problems of many problems in the functional film formed in such a manner, and achieve the effect of preventing a decrease of ozone concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

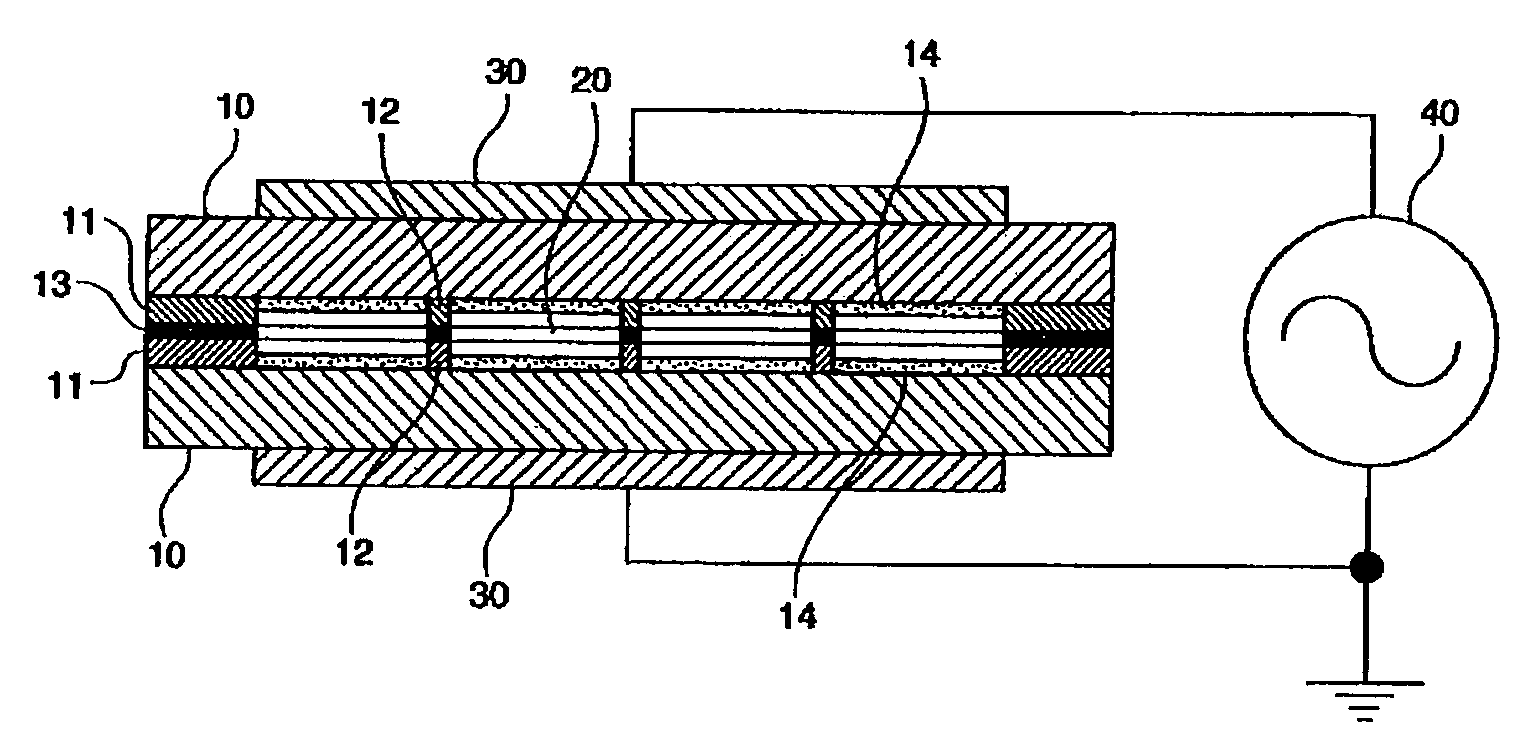

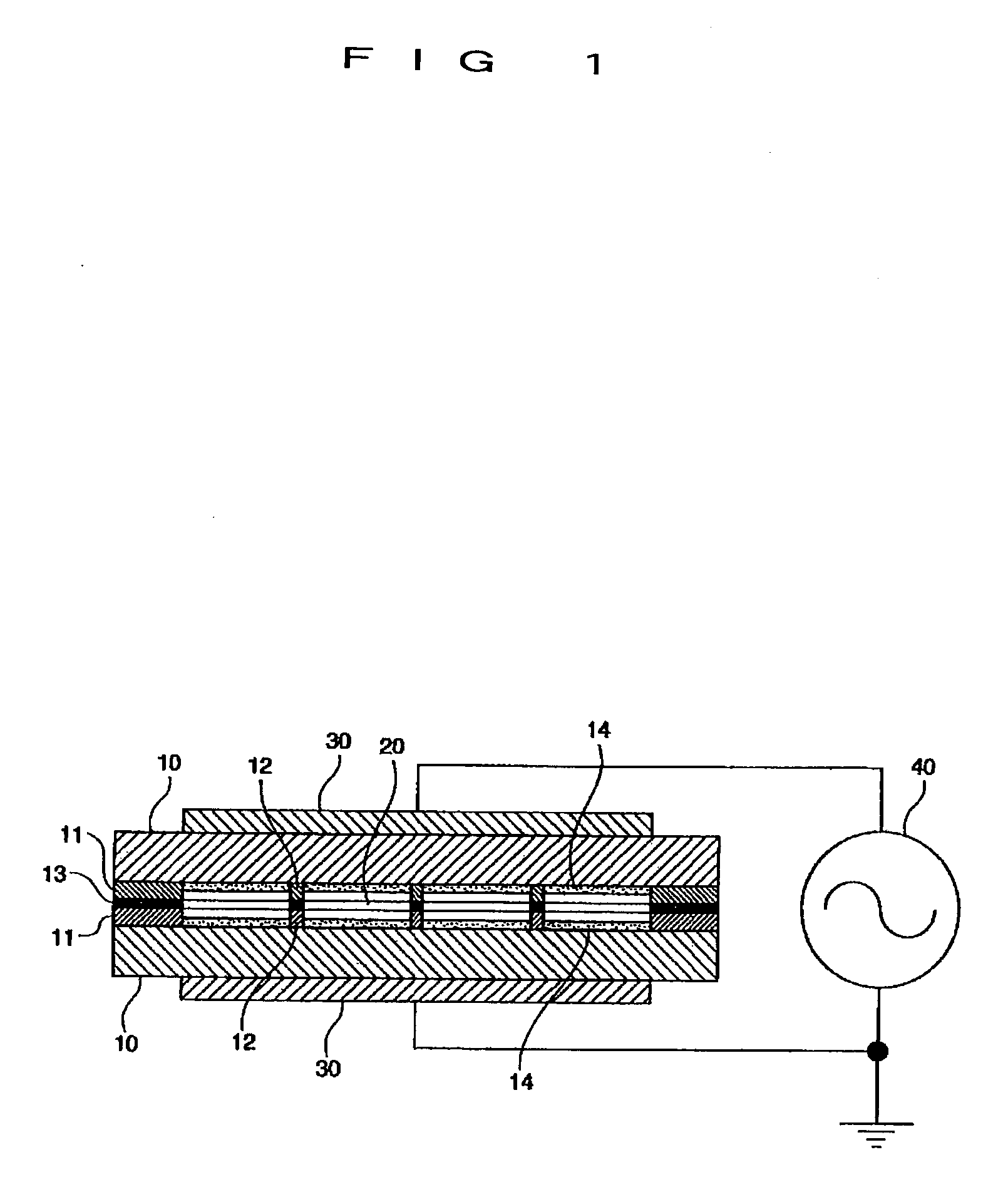

[0046]Next, an advantage of forming the functional films 14, 14 on the opposing surfaces of the dielectrics 10, 10 is explained using a case where the catalytic substance in the functional films 14, 14 is TiO2 and NiO.

[0047]In the above-described discharge cell for an ozonizer, a high purity alumina powder sintered substrate with a purity of 99.5% available from the market was used as the dielectric. The thickness is 0.5 mm. The area of the discharge gap is 100 cm2, and the gap amount is 0.1 mm (100 μm). Oxygen gas with a purity of 99.99% or more was supplied as a raw material gas with a flow rate of 1 L / min and a pressure of 0.2 MPa. Power supply was set to be the maximum power of the ozonizer. The ozone concentration of the produced ozone gas was 10 g / m3 (N) and was extremely low compared with the objective ozone concentration 200 g / m3 (N).

[0048]0.5 vol % of nitrogen gas was added to the above-described high purity oxygen gas. However, the ozone concentration was still 10 g / m3 (N)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com