Sediment containment barrier

a technology of sediment containment and containment barrier, which is applied in the direction of dykes, hydraulic engineering, marine site engineering, etc., can solve the problems of falling out of compliance with many building ordinances and bmps, frequent costly repairs and replacements, and low durability, so as to avoid the need for retrenching, facilitate cleanup, and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

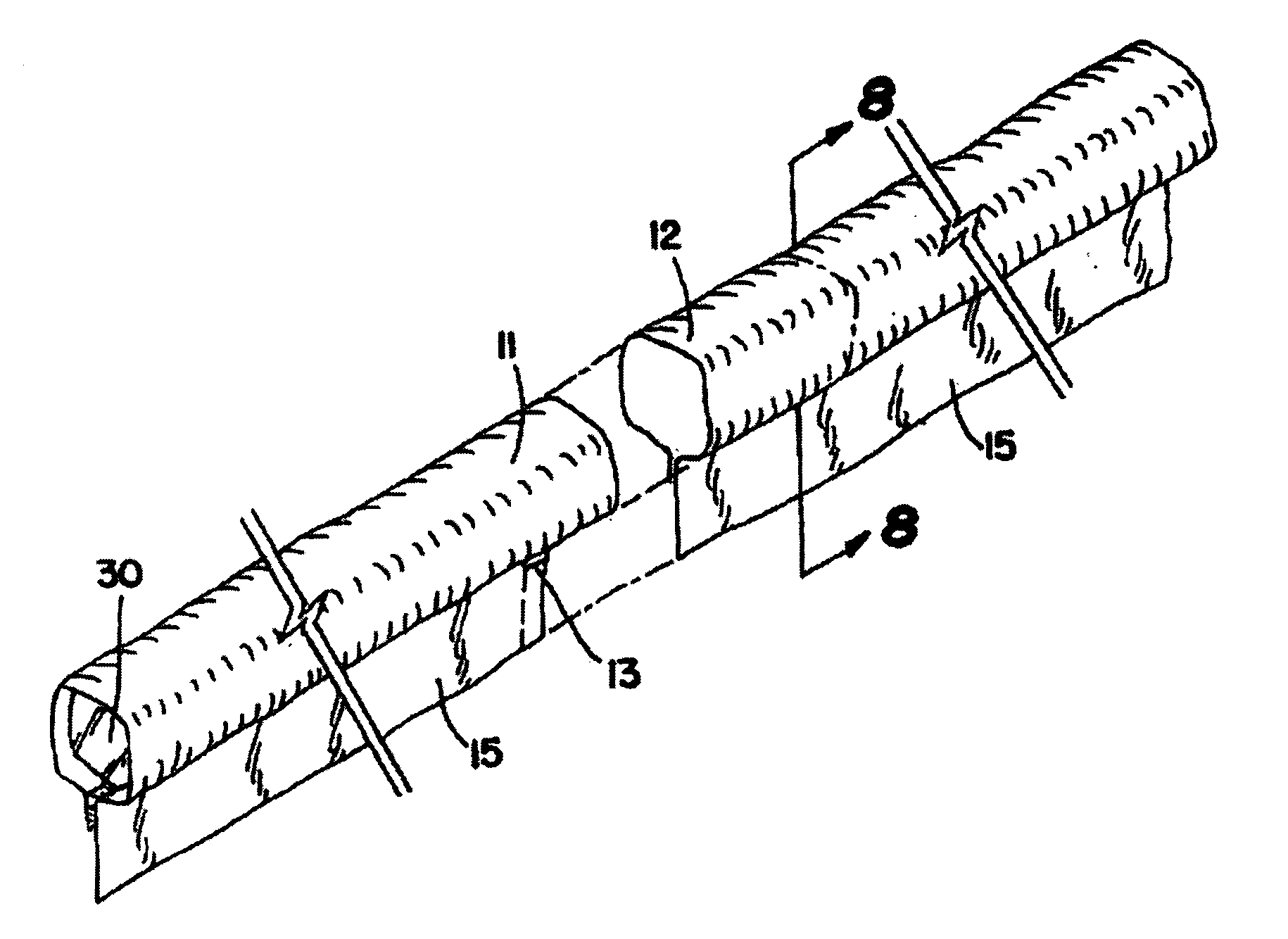

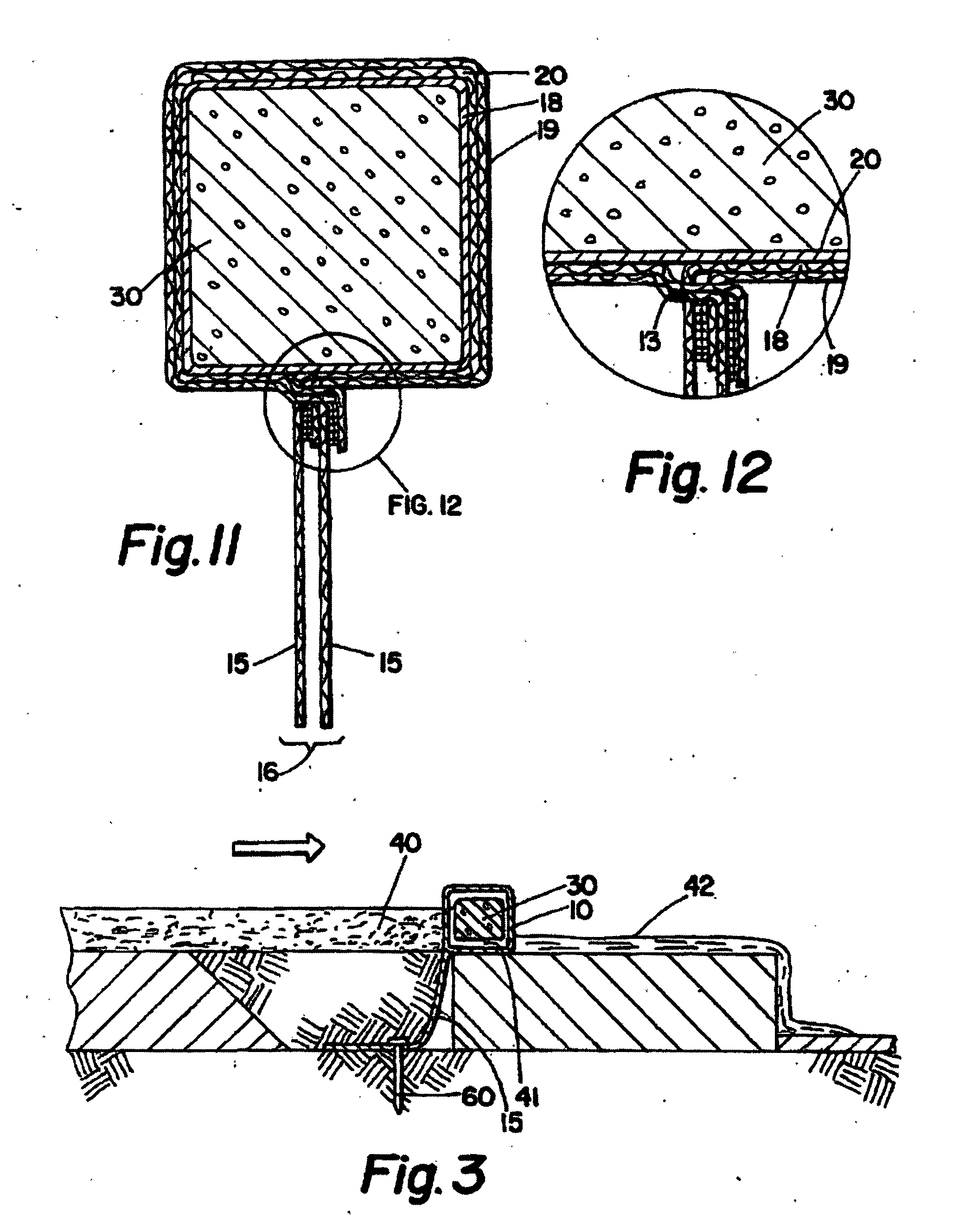

[0035]The present invention is a sediment containment barrier 1 comprising an outer shell 10 and tail 15 made from a filtering material (in a preferred embodiment a high flow monofilament woven polypropylene filter fabric), and an inner core 30 of rebounding foam (preferably polyurethane foam) sealed in a water impermeable (preferably polyethylene) middle layer 20. See FIGS. 4, 5, 7 and 10. In order to accomplish the above-stated objects of the invention, the barrier combines three layers of materials that work together to improve overall performance. Throughout this application the term sediment containment barrier may be interchanged with the common term for the device, wattle.

[0036]Outer shell 10 preferably consists of a high tensile strength (preferably 250-375 lb and less preferably 200-600 lb), high silt and sediment filtration, high water flow and high resistance to clogging, heavy duty, UV stabilized geotextile fabric that is capable of holding up to construction area abuse....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com