Hearing instrument, and a method of operating a hearing instrument

a technology of hearing aids and hearing instruments, applied in the field of hearing aids, can solve the problems of affecting the design degree of freedom of vents, affecting the sound produced by hearing instruments, and unsatisfactory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

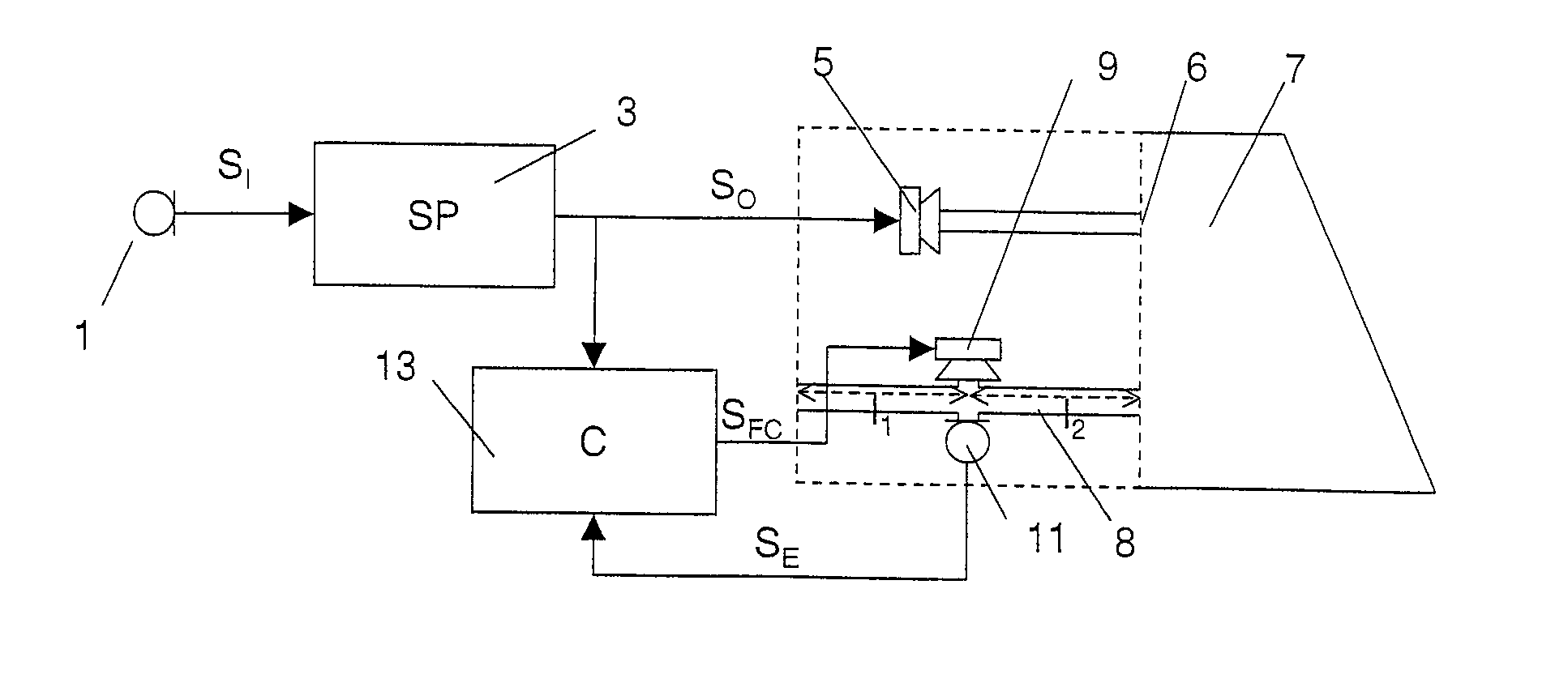

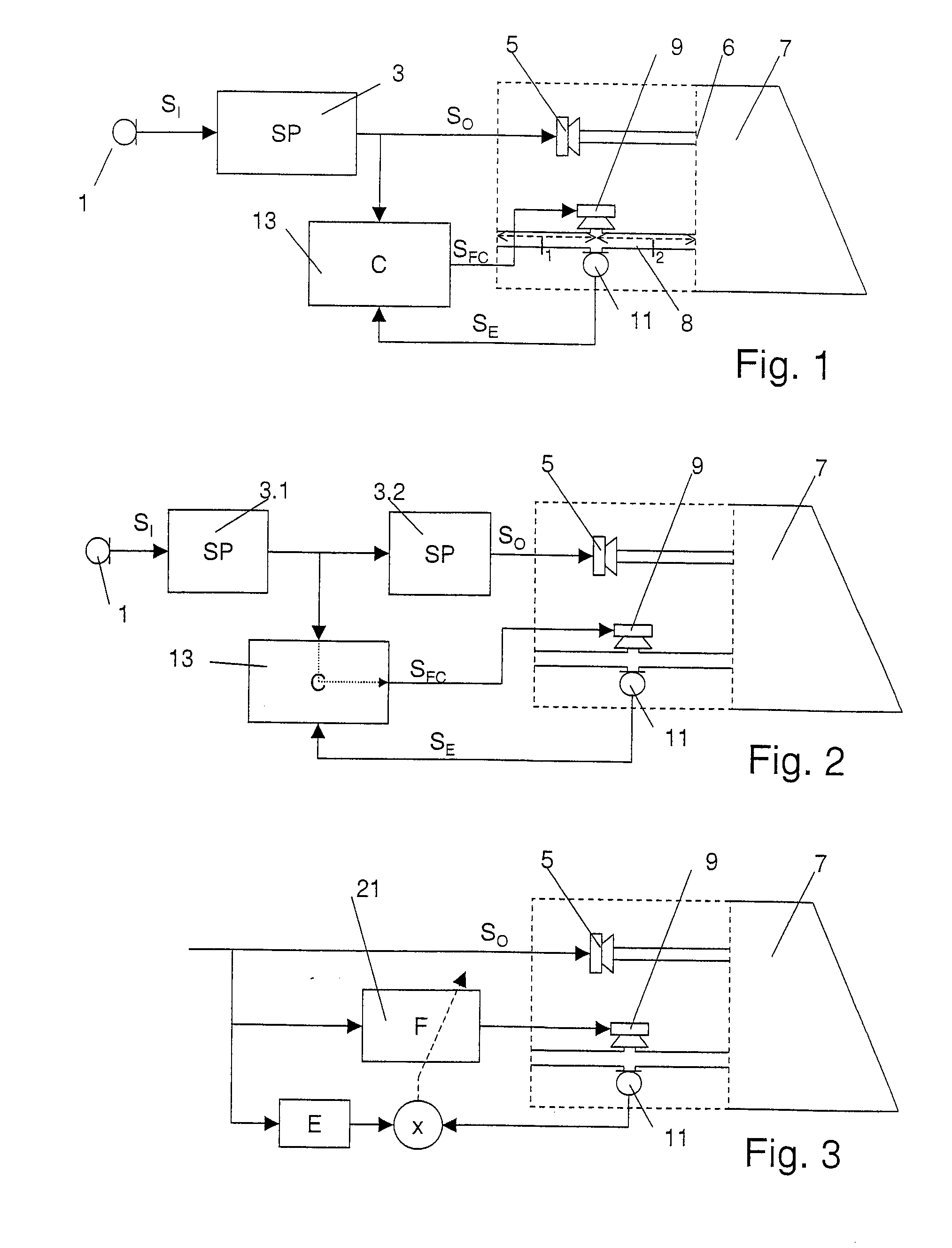

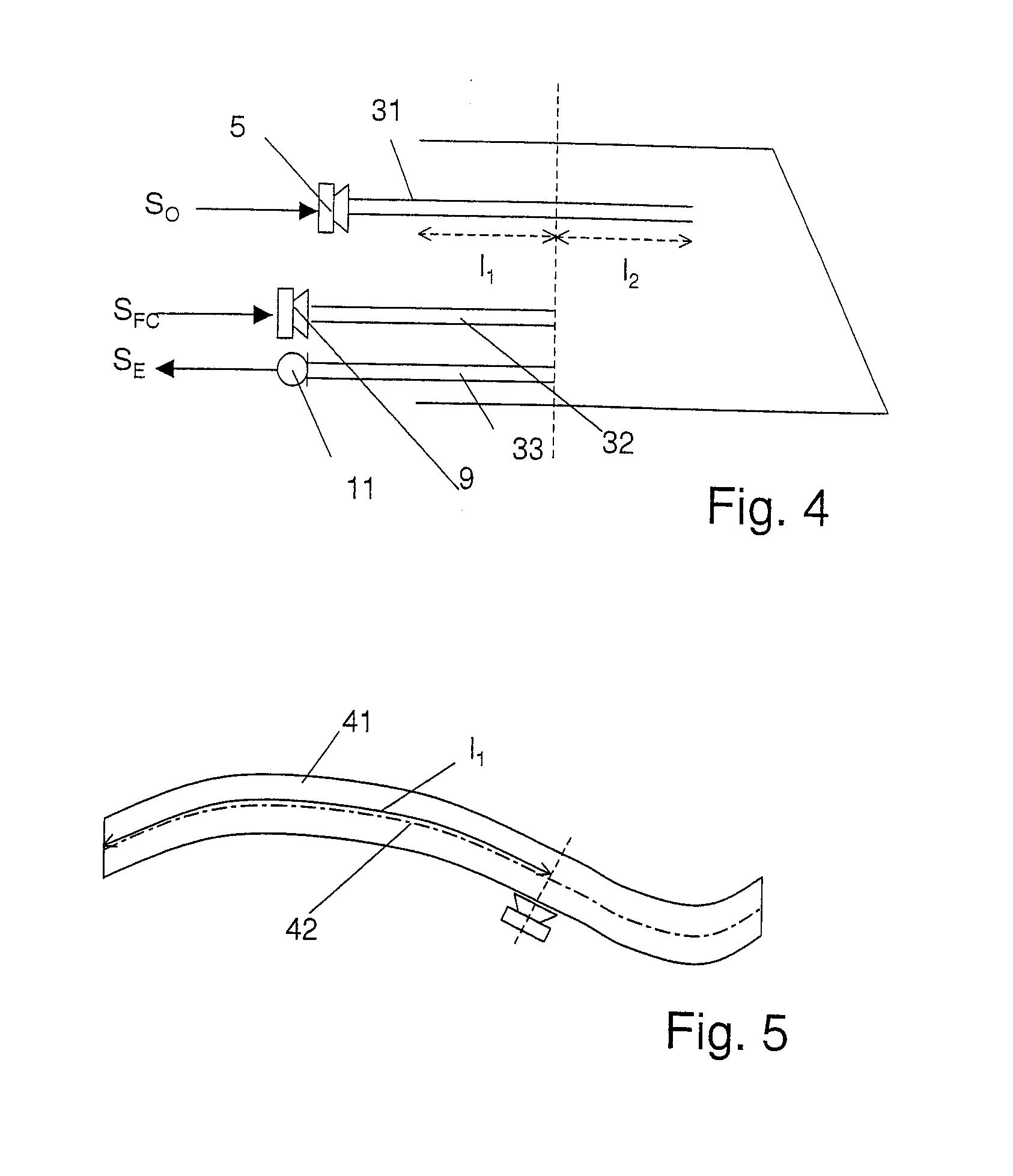

[0050]The hearing instrument represented in FIG. 1 comprises an input microphone 1. In practice, often more than one input microphones are used, and / or in addition to the input microphone further receiving means for receiving signals may be present, such as a telecoil receiver, a receiving unit including an antenna for receiving wirelessly transmitted signals, etc. The electrical input signal SI obtained from the at least one input microphones is processed by a signal processing unit 3 to obtain an electrical output signal SO. The electrical output signal is converted into an acoustic output signal by at least one receiver 5 and is emitted into a remaining volume 7 between the user's eardrum and the in-the-ear-canal-component of the hearing instrument. Between the remaining volume 7 and the surrounding atmosphere, a duct is present. The duct may be a vent 8 of the in-the-ear-canal-component, or it may be formed by the ear canal itself in the case of an open fitting. The hearing inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com