Single Cycle Apparatus for Condensing Water from Ambient Air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

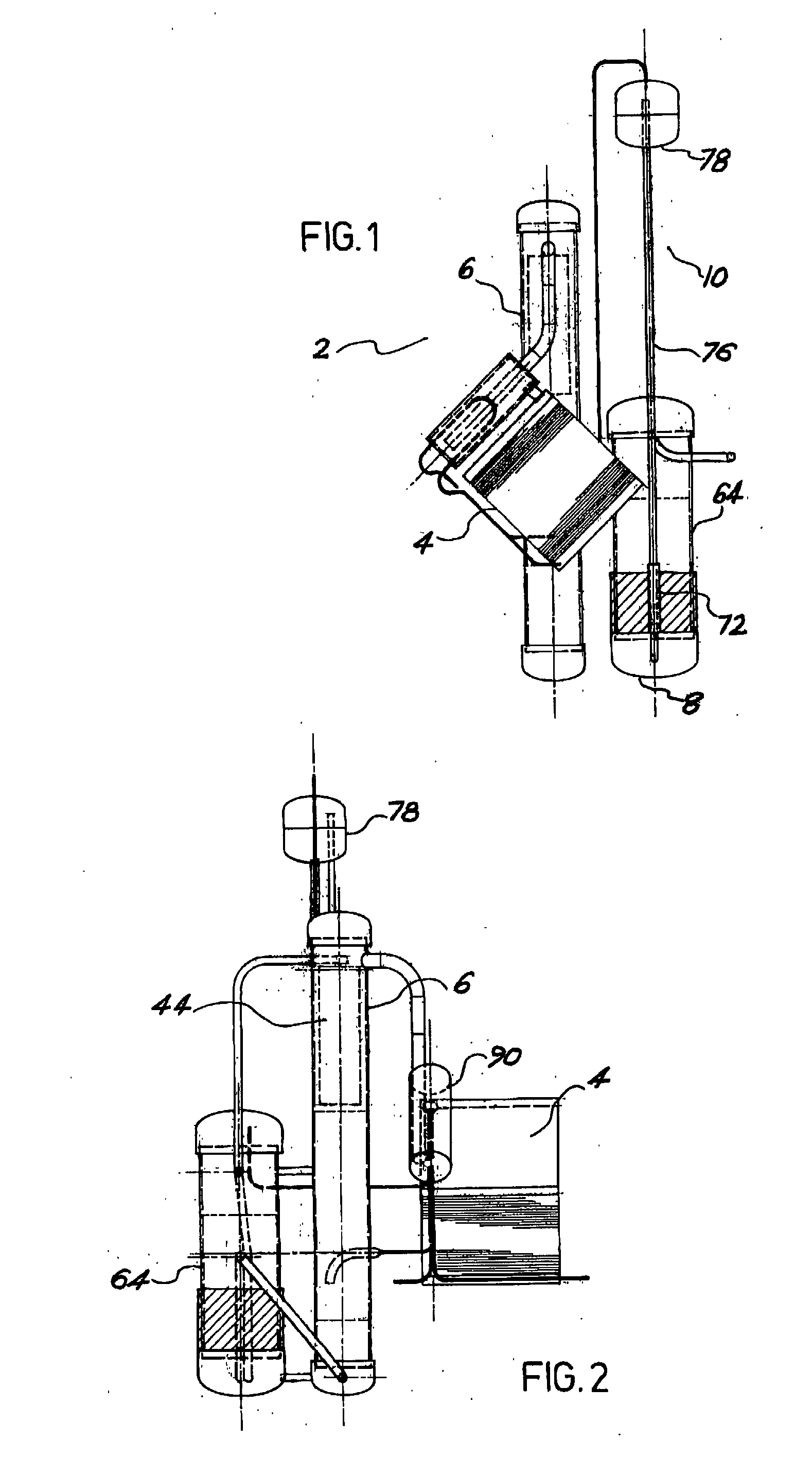

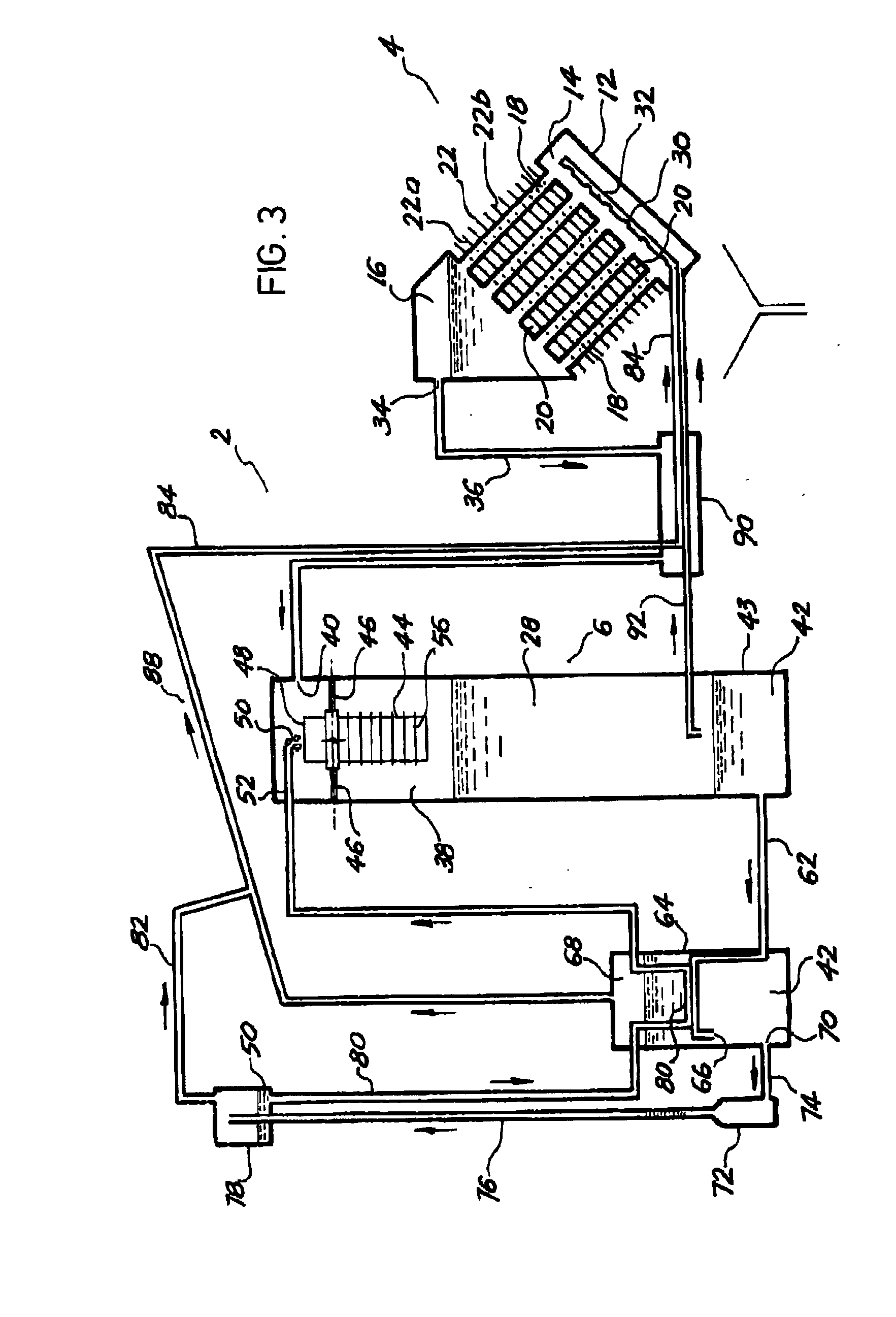

embodiment 190

[0117]A further embodiment 190 of the present invention is illustrated in FIG. 11. This embodiment differs from that shown in FIG. 10 in that the fan 174 blows ambient air across the cooling fins 170 of the evaporator 166 during the first stage of the work cycle which is then directed to rectifier cooling fins 191. The ambient air draws off heat from the rectifier fins causing the gaseous ammonia in the conduit trap 158 to condense. The ambient air also draws off heat from gaseous ammonia flowing into the evaporator which has not condensed in the conduit trap 158, causing the remaining gaseous ammonia to condense and collect in the evaporator. The evaporator 166 in this embodiment therefore serves as both a condenser for condensation of the gaseous ammonia and to facilitate evaporation of gaseous ammonia from the liquid ammonia for return to the heating tank during the second stage of the work cycle.

[0118]During the second stage of the work cycle, the fan continues to operate such t...

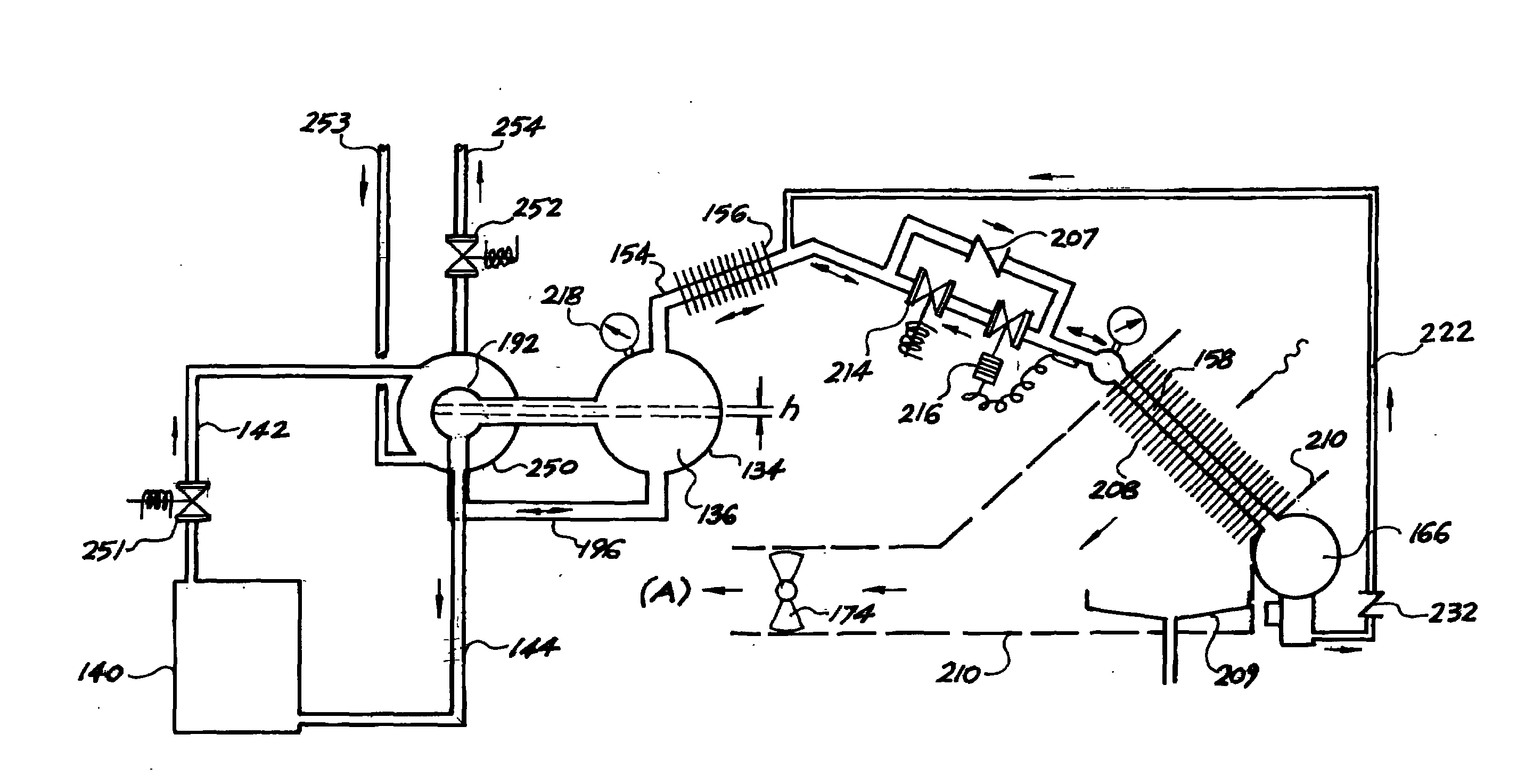

embodiment 200

[0121]A yet further embodiment 200 of the present invention is shown in FIG. 12. In this apparatus, a solenoid operated control valve 202 is provided which is opened during the first stage of the work cycle of the apparatus to allow the flow of ammonia to the evaporator 166. The control valve 202 is closed for the second stage of the work cycle, and the flow rate of gaseous ammonia returning to the heating tank 134 is controlled by throttle valve 204 arranged in the conduit trap 158. The throttle valve incorporates a fluid expansion thermostat 206 for sensing the temperature of the cooling fins 170 of the evaporator 166 and effecting opening or closing of the throttle valve in response to variation in the temperature, to regulate evaporation of the liquid ammonia and thereby condensation of water from the ambient air.

[0122]For any given prevailing atmospheric conditions, there is a specific humidity value measured in grams of water vapour per kilogram of air. For example, a specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com