Tool tote

a technology for totes and tools, applied in the field of totes for transporting and storing tools, can solve the problems of material being prone to wear, and achieve the effect of reducing the dumping of totes and reducing the dumping of contents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

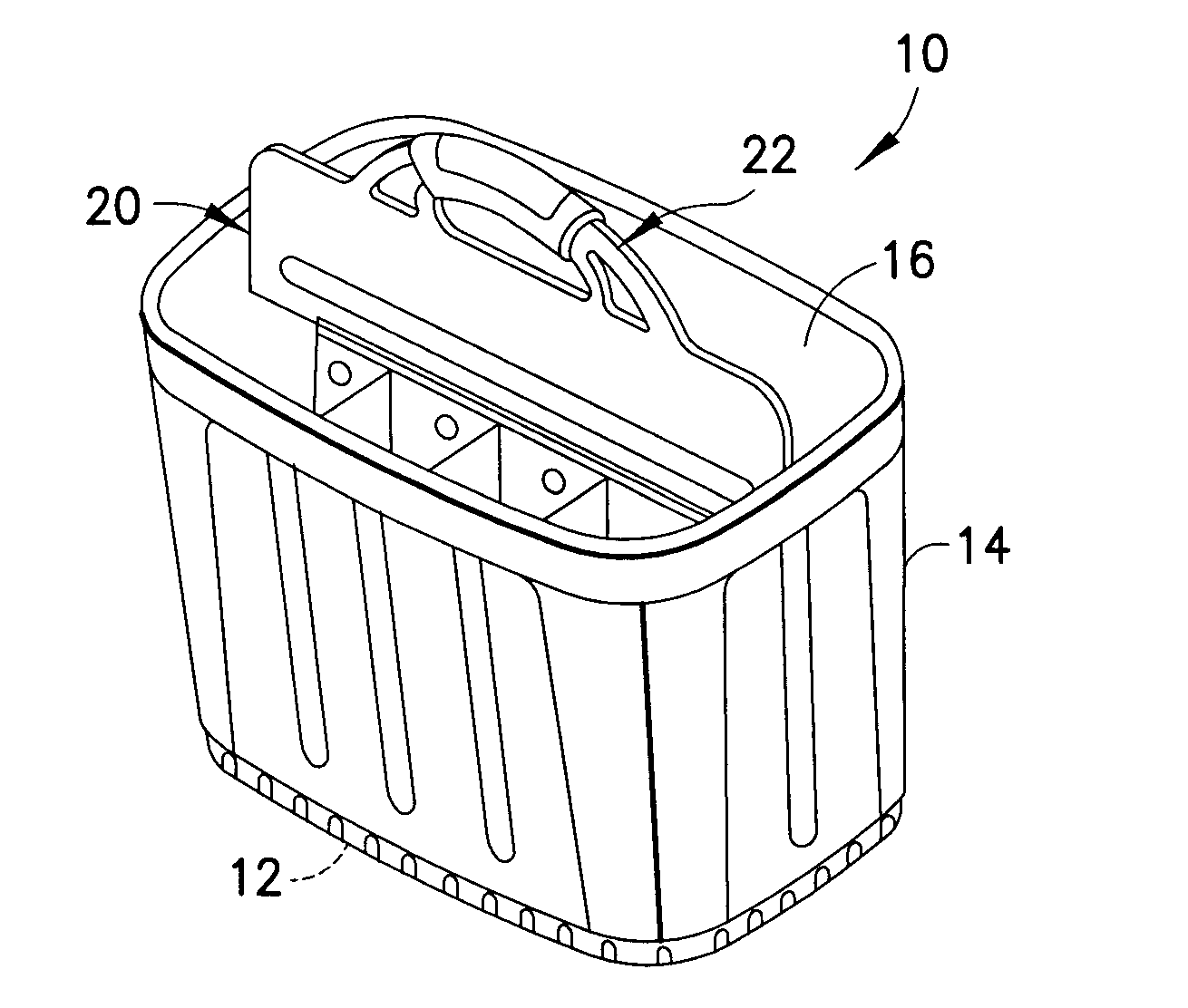

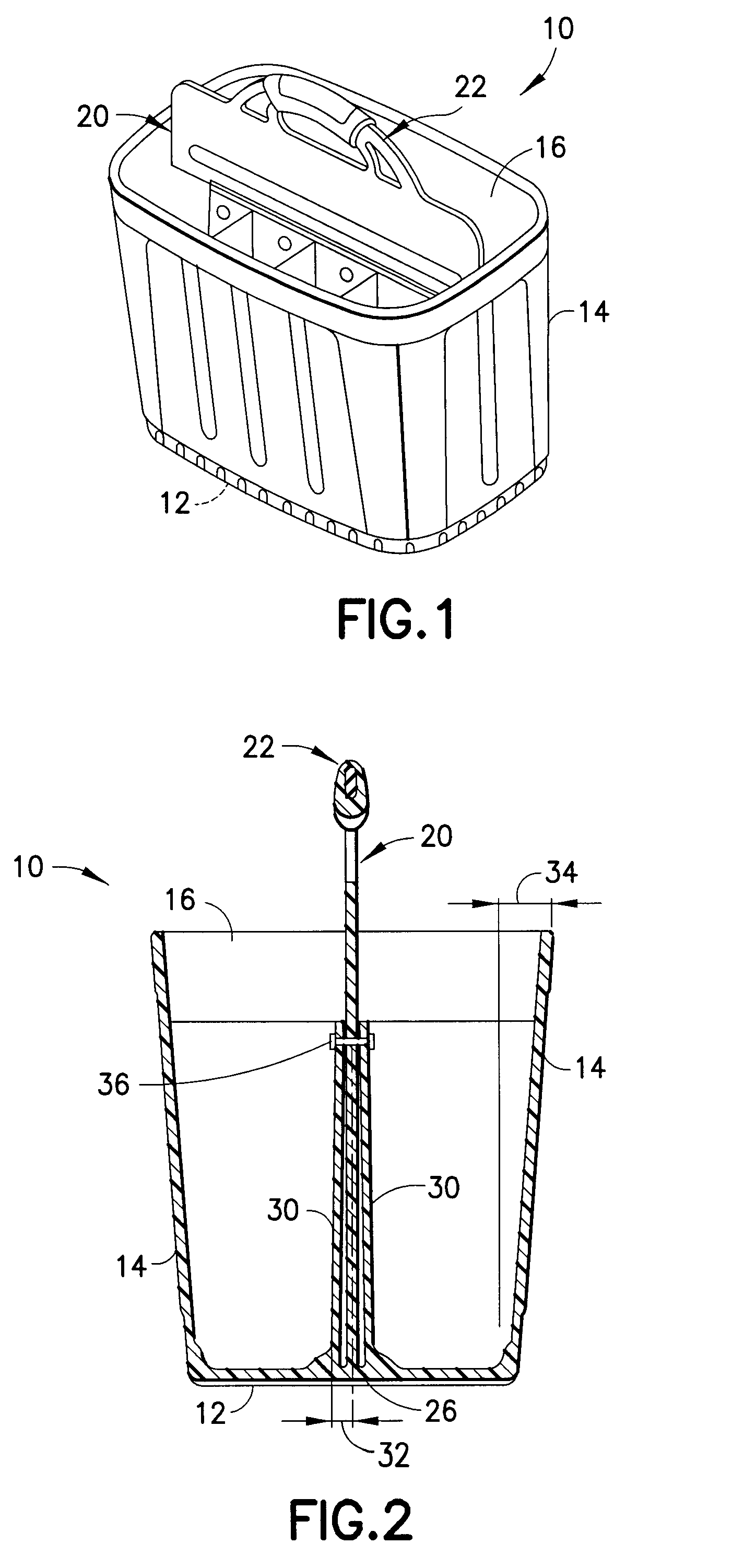

[0022]In FIG. 1, a tool tote of the present invention is designated generally by the reference numeral 10 and is hereinafter referred to as “tote 10.” Tote 10 is a receptacle having a bottom 12, at least one outside surface that defines an outer wall 14 that extends substantially perpendicularly from a peripheral edge of the bottom and defines an open top 16, a center panel 20 extending substantially perpendicularly from the inside surface of the bottom, and a handle 22. An upper end of the center panel 20 terminates in the handle 22, which is positioned near or at the open top 16 a suitable distance above the top edges of the outer wall 14 to allow the tote 10 to be carried comfortably. Although the tote 10 is especially adapted for the carrying of tools, the present invention is not limited in this regard and other devices, articles, and / or materials may be transported using the tote.

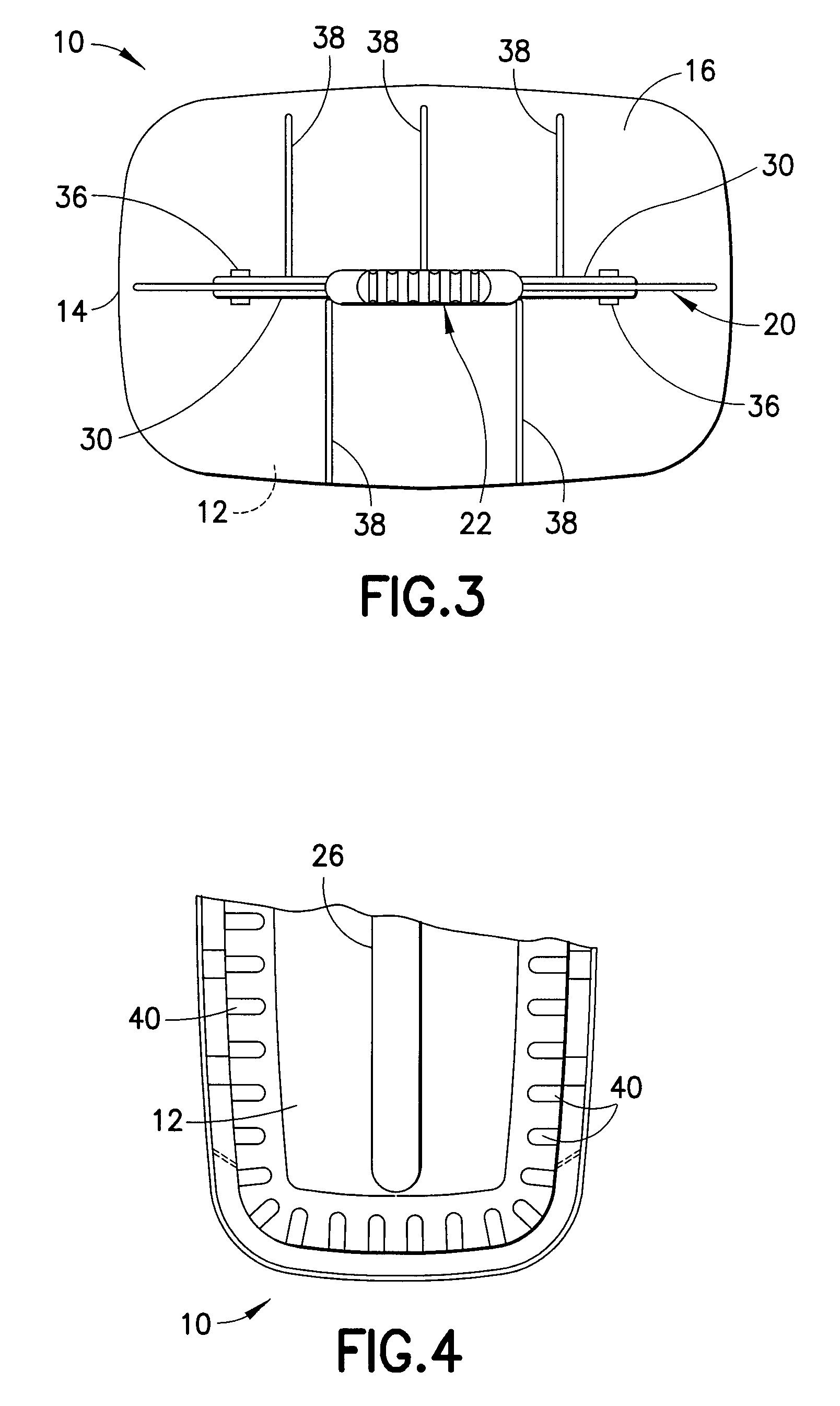

[0023]As is shown in FIGS. 2 and 3, the center panel 20 extends the substantial length of the tote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com