Extruded Structural Beam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

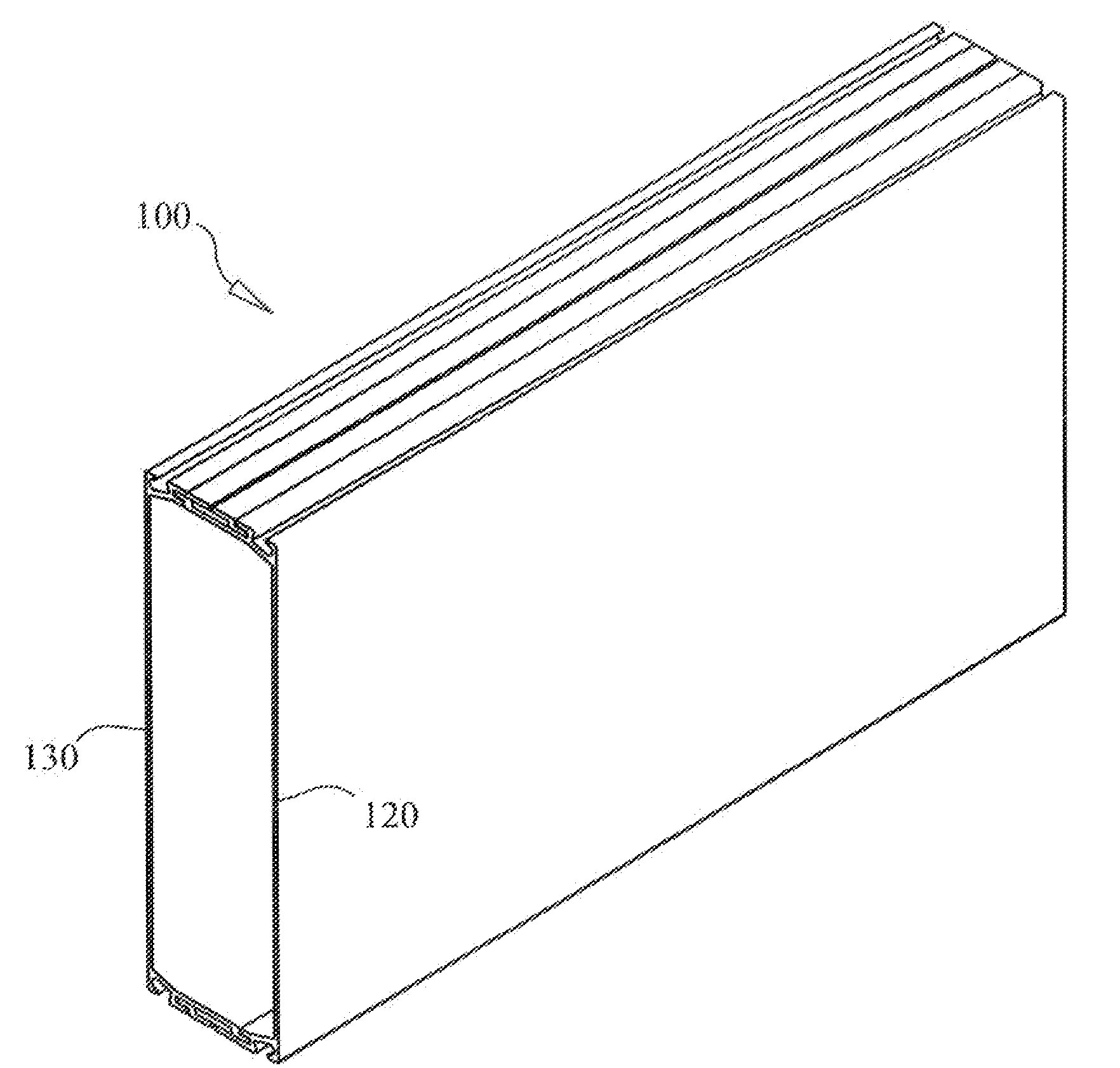

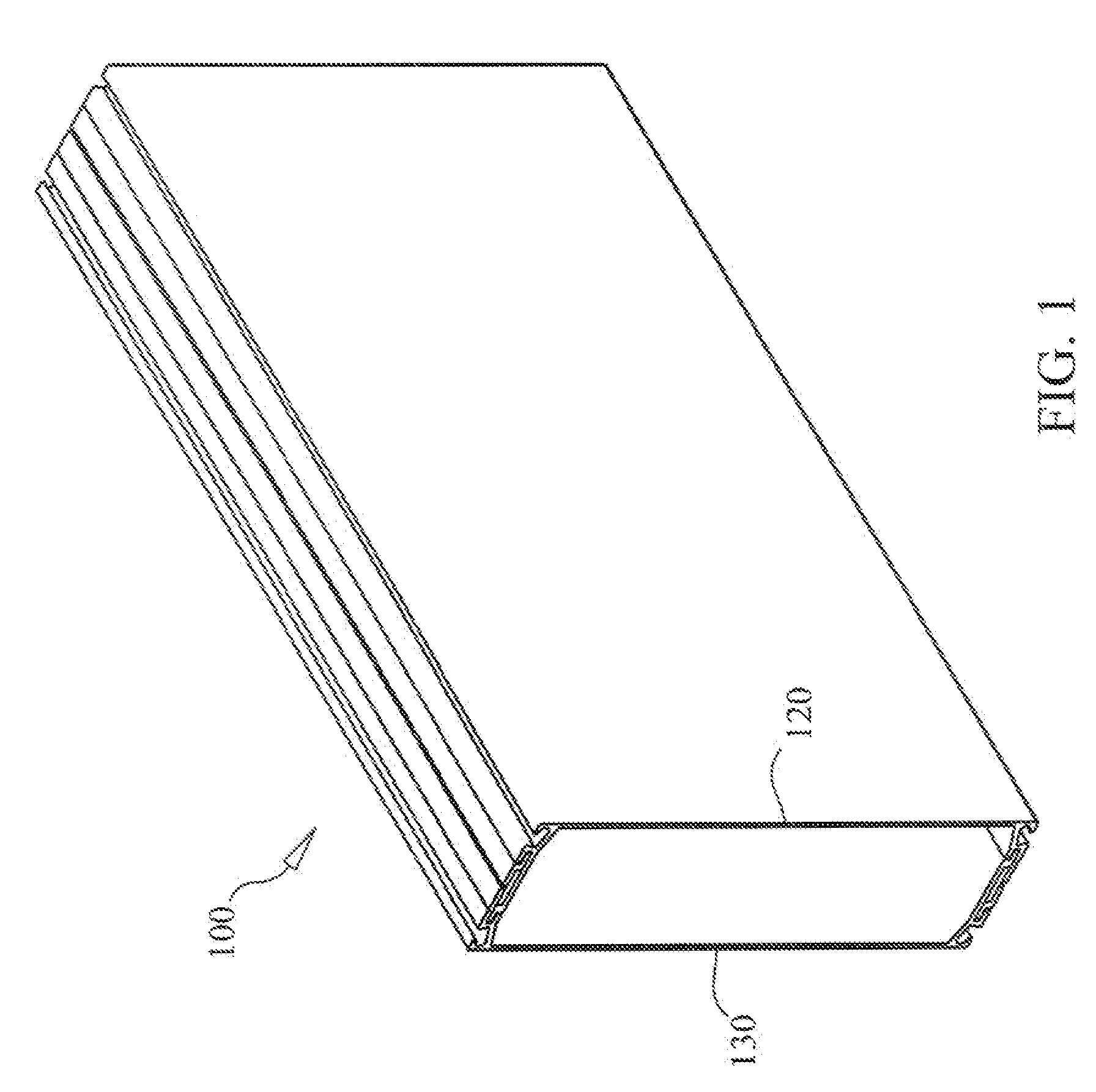

[0036]FIG. 1 shows the new beam 100 is comprised of a first member 130 and a second member 120. The beam 100 is shown assembled to form a rectangular hollow shape. Each member is a standard beam shape that is used in construction, of screen enclosures and extruded through a die process to various lengths. First member 130 and second member 120 are assembled in the field to form the new structural beam 100. The materials used to make beam 100 are the same aluminum alloys that are used in the construction of aluminum, screen enclosures. The wall thickness of first member 130 and second member 120 will vary between each size change and are dependant on code requirements to meet deflection criteria in the local and state building codes.

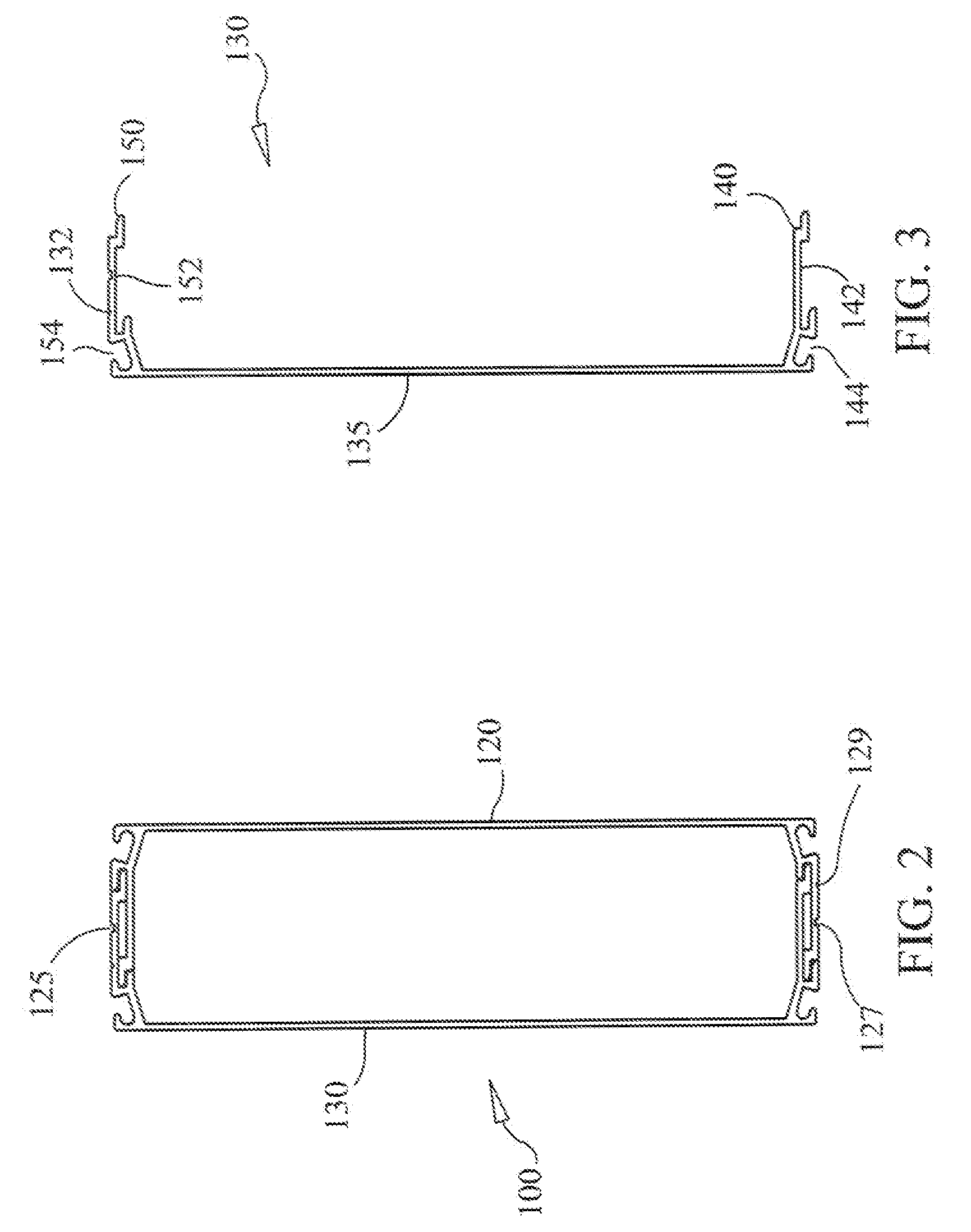

[0037]Referring now to FIG. 2 and FIG. 3, a cross section of the beam 100 is shown including the coupling of the flanges. A longitudinal slot 125 on top flange 150 and longitudinal slot 127 on bottom, flange of second member 120 show where screws are used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com