Lng Regasification Configurations and Methods

a technology of configuration and gasification, applied in the field of gas processing, can solve the problems of imposing constraints on specific gas components, affecting the quality of gas components, and a substantial fraction of the world lng supply is rich lng with non-compliance with heating values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

Exemplary Calculation of Components in Selected Streams

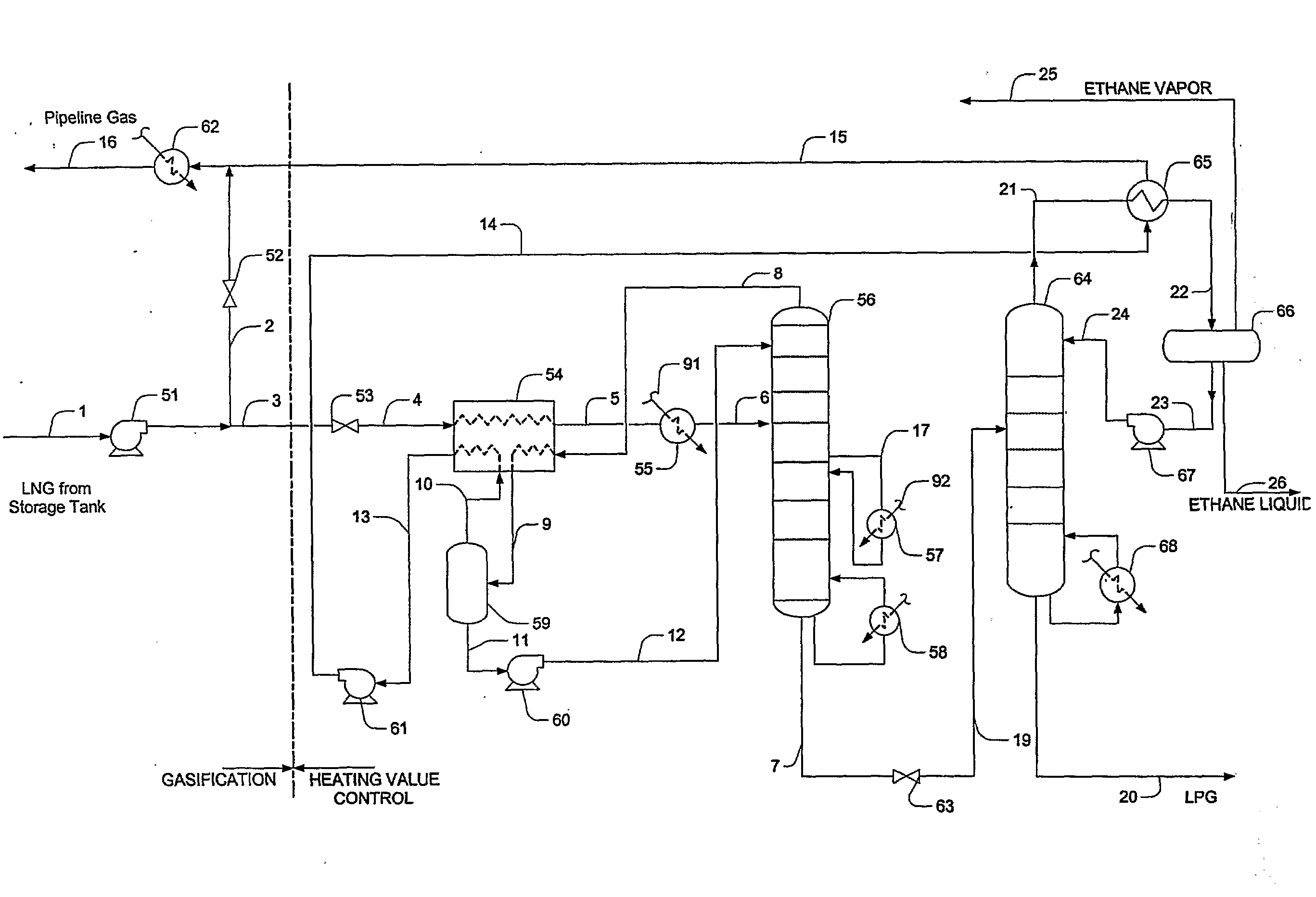

[0056]In an exemplary configuration substantially identical with the plant configuration as shown in FIG. 1, the mol fraction of various components of selected streams were calculated, and the results are listed in Table 1 below. LPG is the C3+ bottom fraction of the demethanizer stream 20, and the pipeline gas is depicted as stream 16.

TABLE 1Com-ponentLNG FeedEthaneLPGPipeline GasN20.00650.00000.00000.0073C10.88160.01760.00000.9878C20.05220.97230.00530.0042C30.03280.00920.54070.0006iC40.00710.00000.12060.0000NC40.01070.00000.18180.0000iC50.00400.00000.06730.0000NC50.00200.00000.03370.0000C6+0.00300.00000.05050.0000Heat1,1531,7502,985999ValueBtu / SCF(HHV)MMscfd5002530450Barrel per218,00016,00021,000181,000day

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com