Variable Valve Drive Device, Engine, and Motorcycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The present invention will further be described below concerning the best modes with reference to the accompanying drawings.

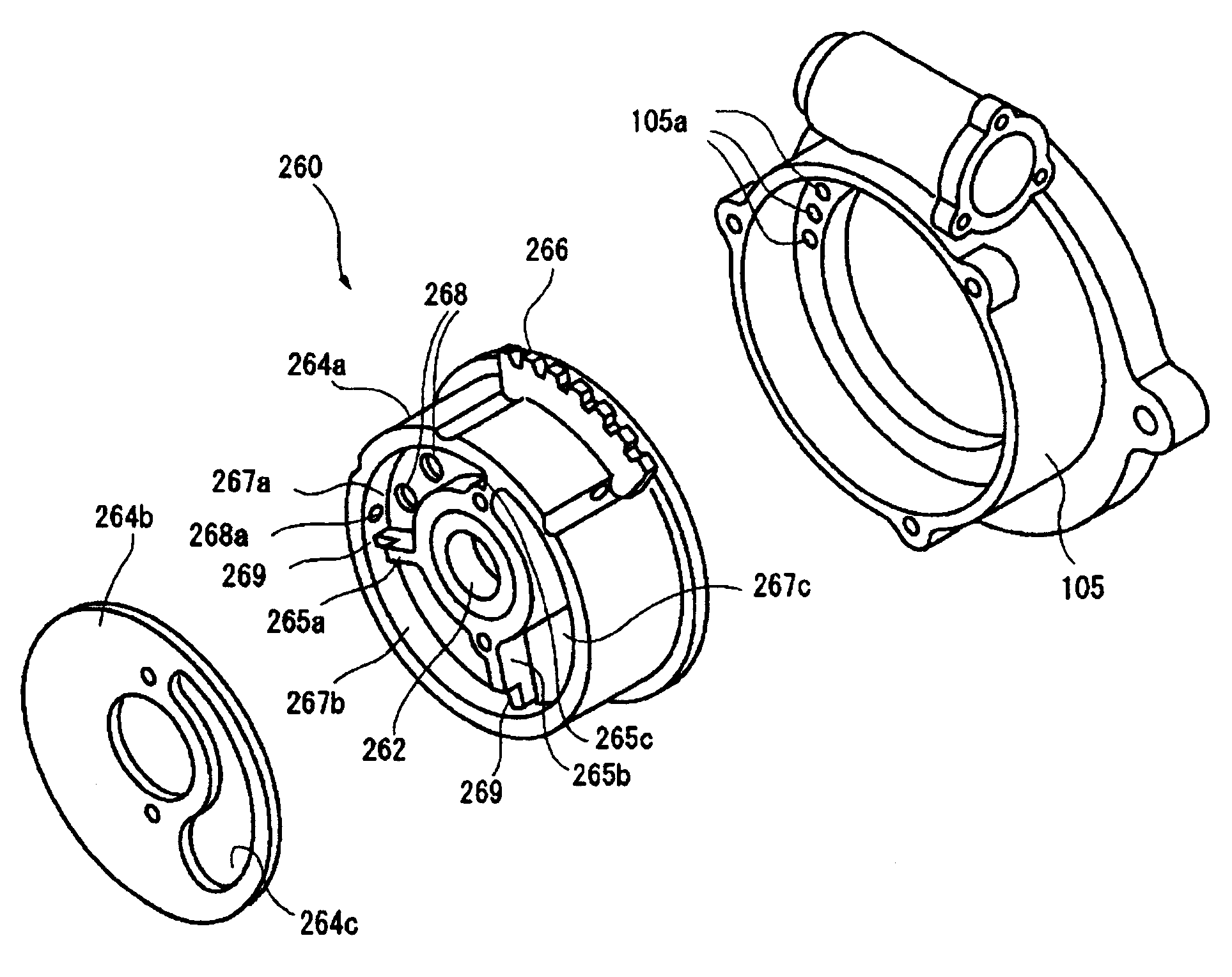

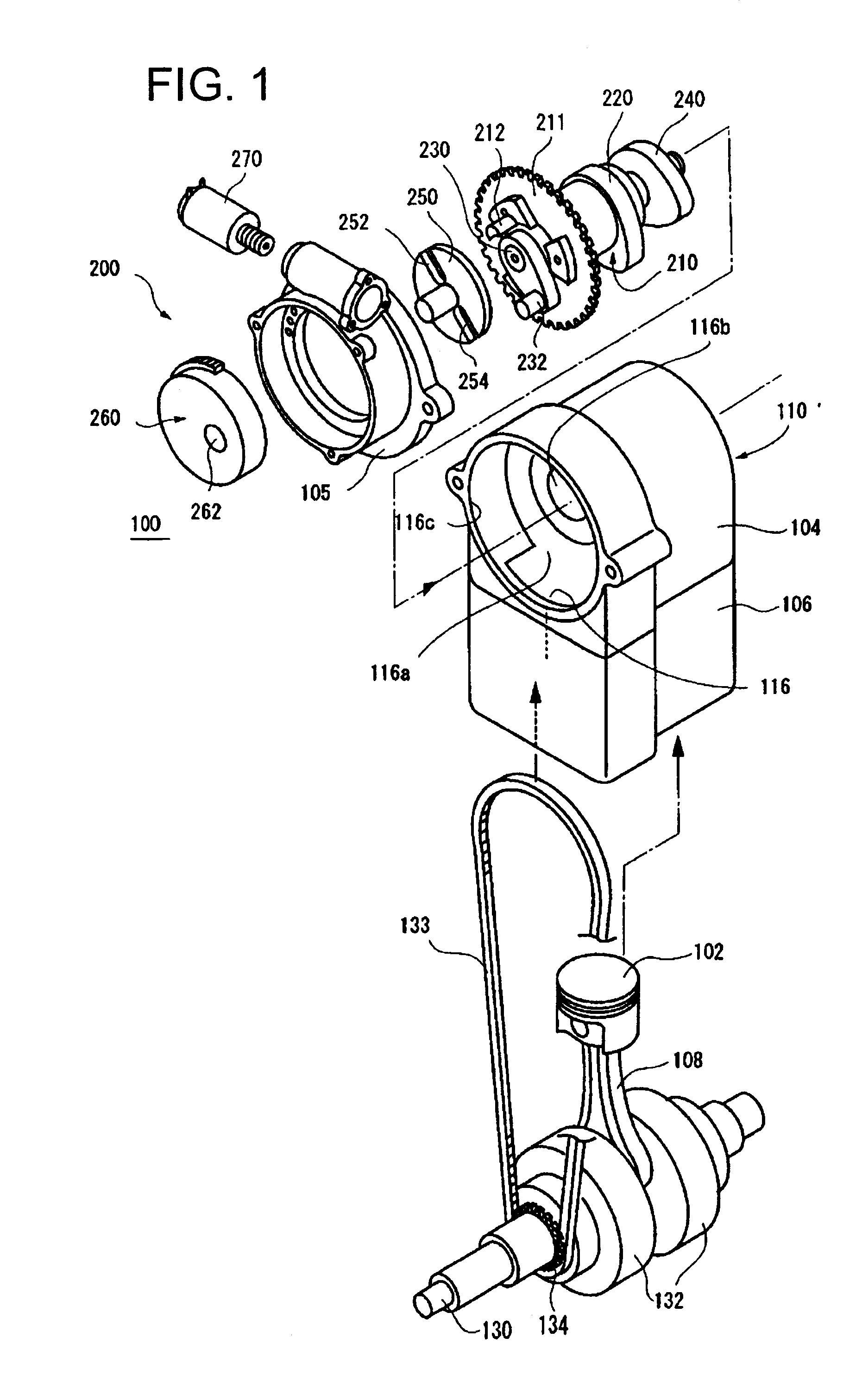

[0031]FIG. 1 shows an exploded perspective view of the substantial part of an engine provided with the variable valve drive device according to an embodiment of the present invention.

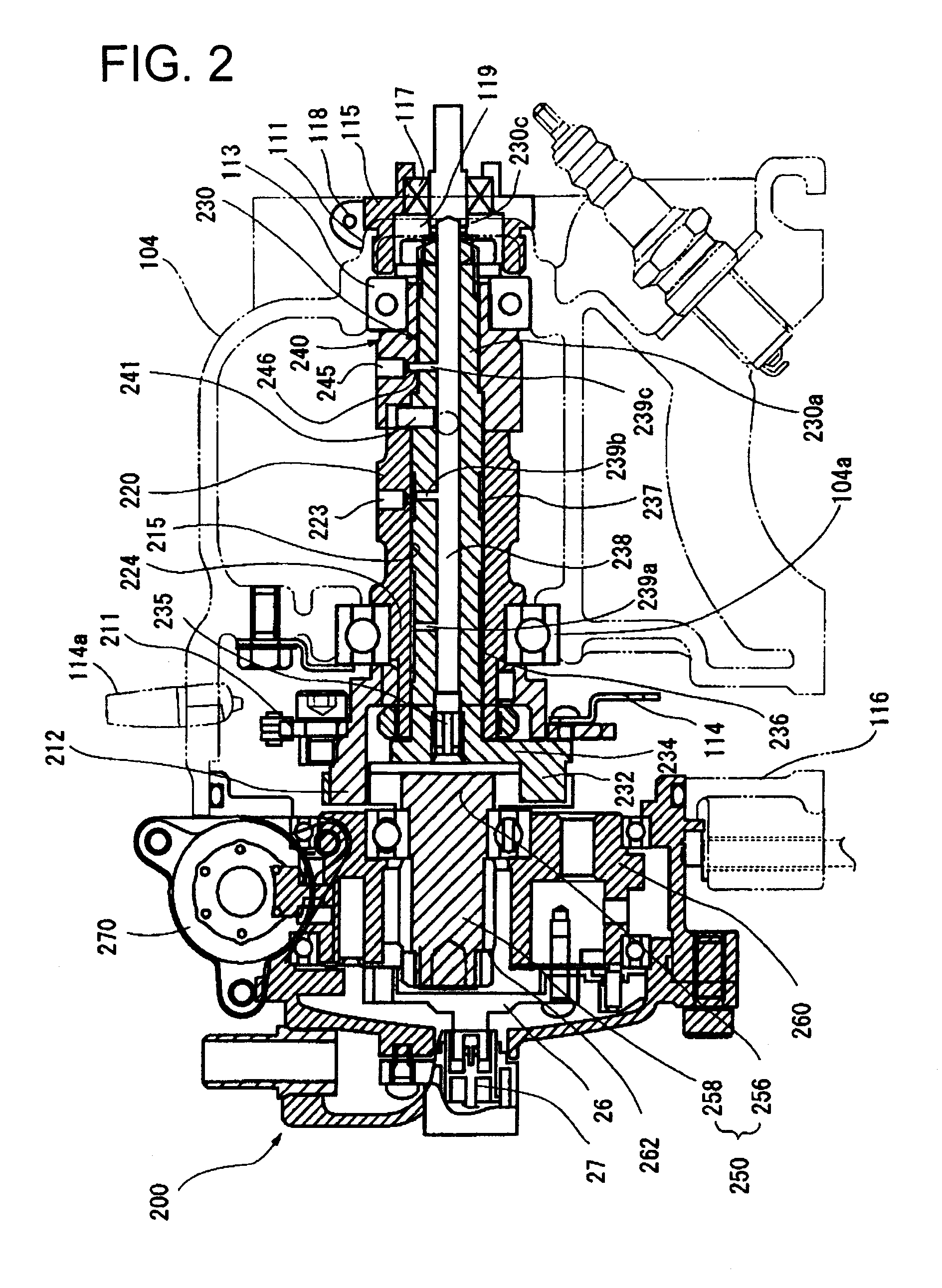

[0032]FIG. 1 shows an engine 100 that includes an engine main body 110 having a cylinder part 106 having slidably housed therein a piston 102 and a cylinder head 104, a crankshaft 130 housed in a crank case 112 (refer to FIG. 10), and a variable valve drive device 200.

[0033]In the engine 100, a periodical rotational phase difference is set up between an exhaust cam block 220 and an intake cam block 240 by the variable valve drive device 200 that is arranged substantially in parallel with the crankshaft 130 so as to make the opening and closing valve timing variable according to the respective rotations. Accordingly, the valve overlap is made variable according to the number o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com