Back-illuminated type imaging device and fabrication method thereof

a technology of back illumination and imaging device, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, electrical devices, etc., can solve the problems of increasing fabrication cost, fixed pattern noise, and becoming more difficult to perform such a removal work, so as to prevent the increase of fabrication cost and the resistance between pads and wirings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044]Hereinafter, embodiments of the invention will be described with reference to the accompanying drawings.

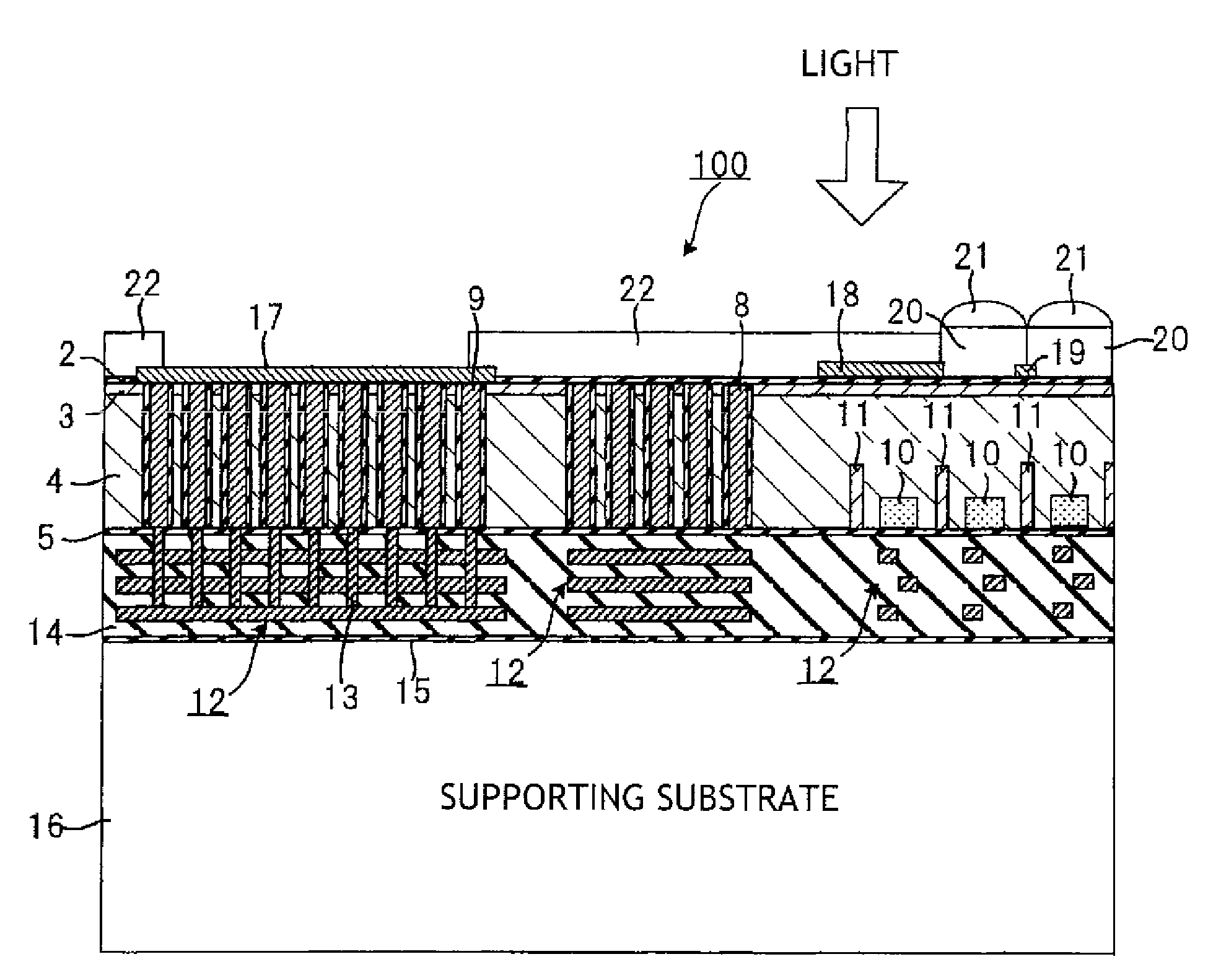

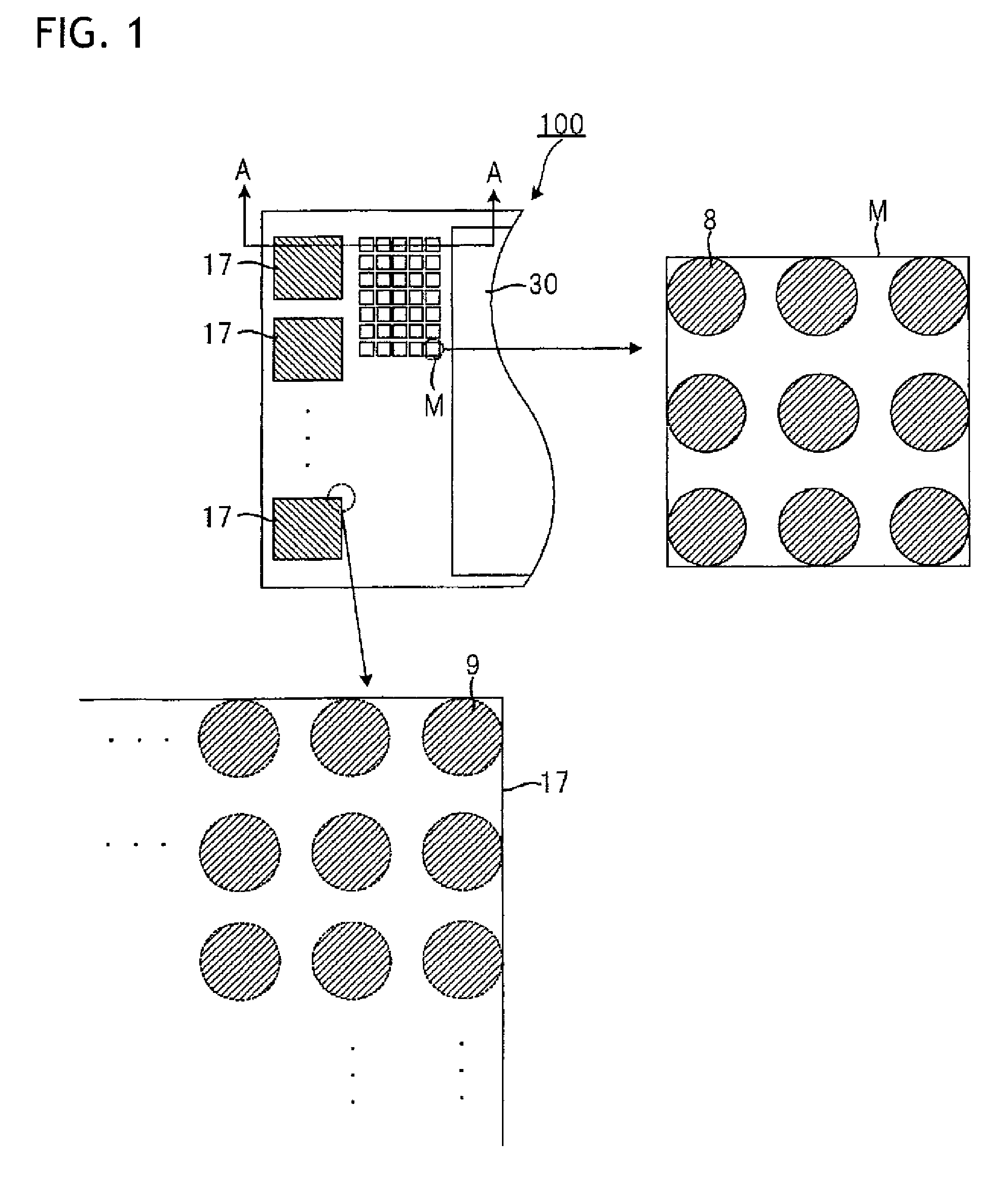

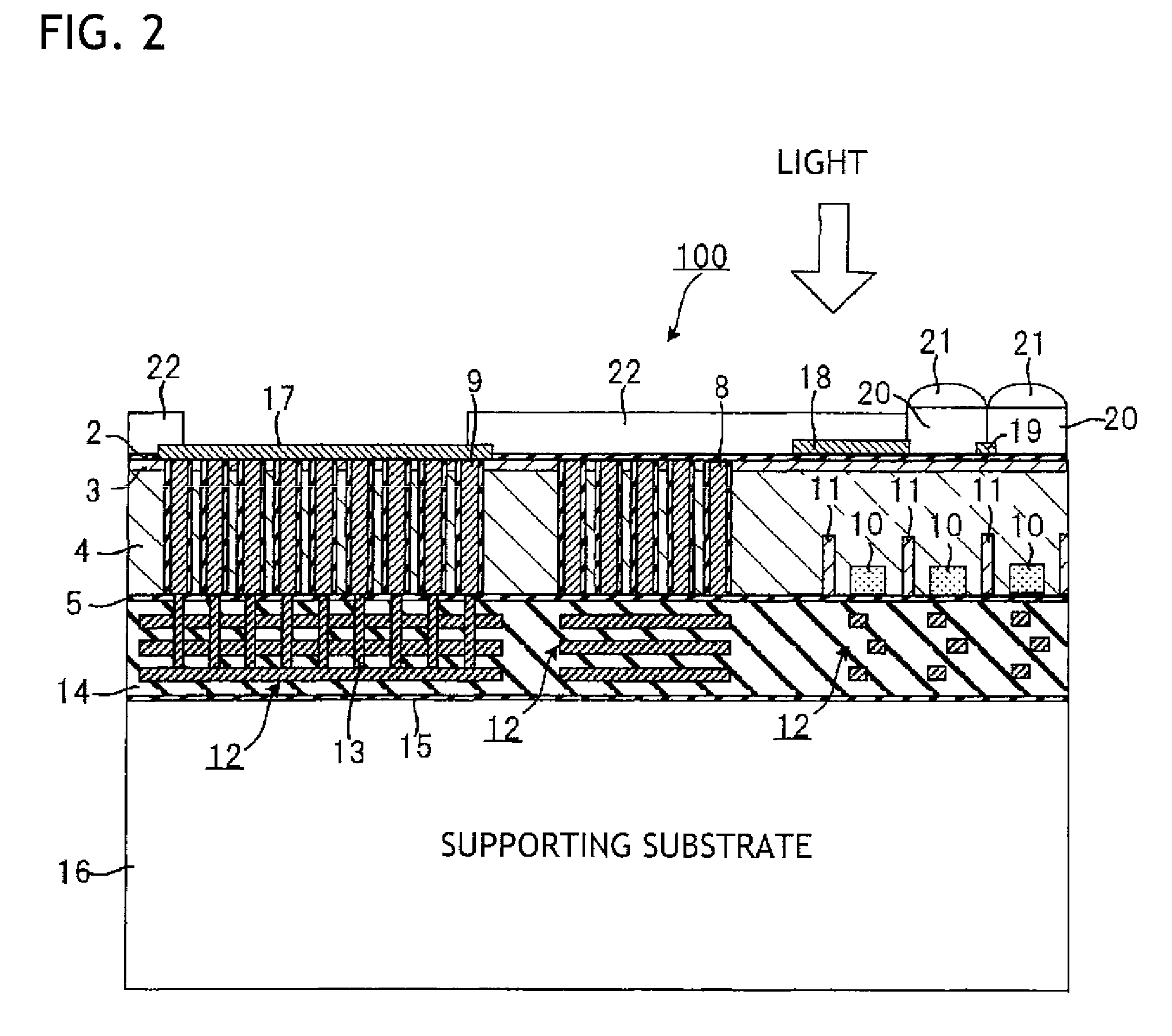

[0045]FIG. 1 is a schematic plan view of a back-illuminated type imaging device according to an embodiment of the invention, when viewed from a light incidence side (a back-surface side). FIG. 2 is a schematic sectional view taken along the line A-A of FIG. 1.

[0046]As shown in FIG. 1, the back-illuminated type imaging device 100 includes an imaging area 30 for receiving light to perform imaging; a mark forming area in which formed are a large number of alignment marks M that are used to align components (charge storage areas for storing charges, a signal output portion for outputting signals corresponding to the charges stored in the charge storage areas, and the like) on a front-surface side opposite to the back surface, in which the imaging area 30 is formed, with components on the back-surface side; and a pad forming area in which a large number of pad portions 17 that ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com