Regenerator matrix with mixed screen configuration

a technology of a generator and a matrix, which is applied in the direction of indirect heat exchangers, refrigeration components, lighting and heating apparatus, etc., can solve the problems of degrading the performance of the cooler, affecting the operation of the cooler, so as to achieve a large void volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

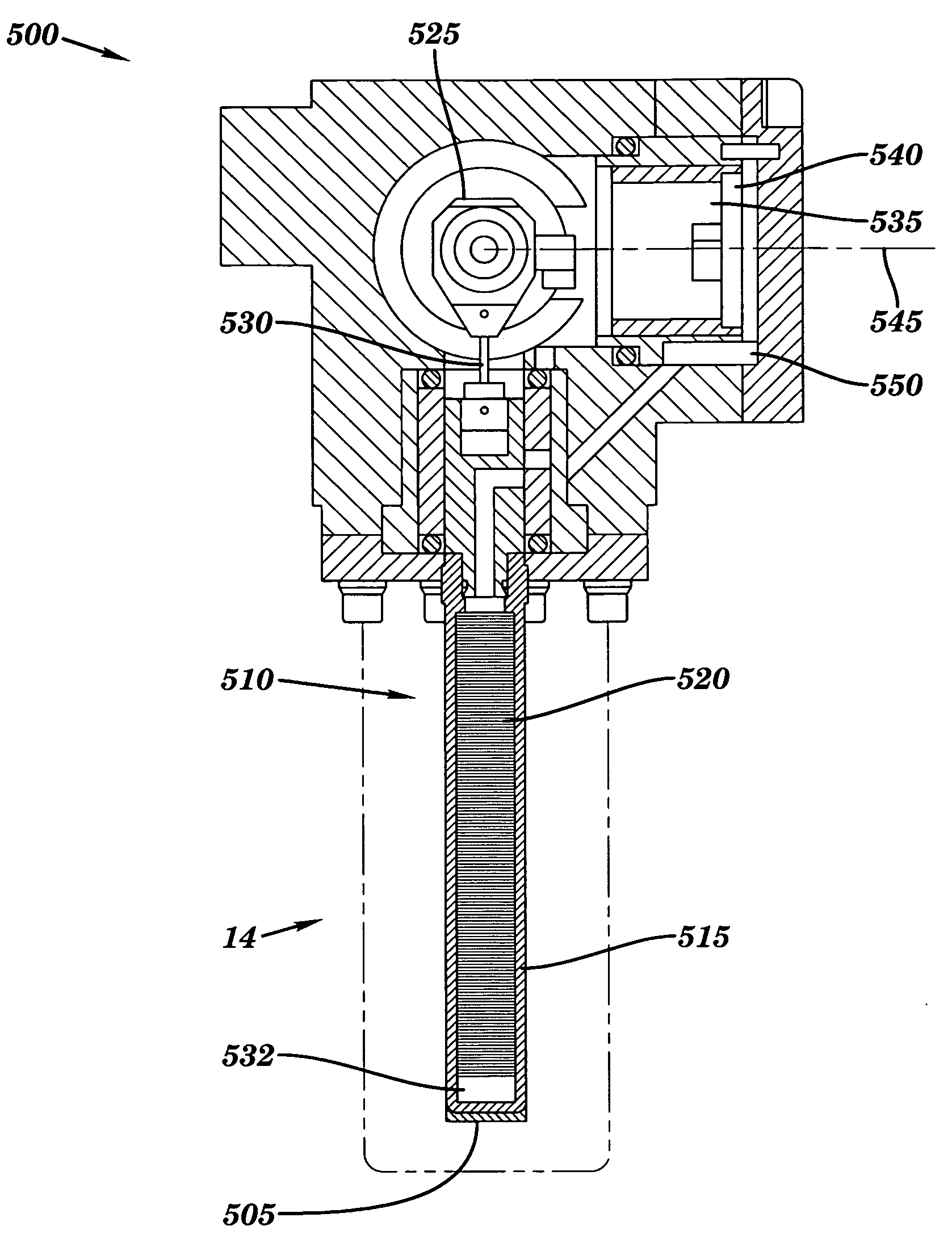

[0043]The preferred embodiments of the present invention are illustrated in the accompanying detailed description and drawings. FIG. 3 depicts a cross-sectional view of a Stirling cycle cryocooler 500 used for cooling components to cryogenic temperatures, e.g. to less than about 135° K. or more particularly to less than about 80° K. FIG. 3 shows an element to be cooled 505 attached to the cold end of a cold well assembly 510. The cold well 510 comprises a thin walled cylindrical cold well tube 515, sealed at a cold end thereof and a cylindrical regenerator piston 520 movably supported within the cold well tube 510. A drive coupling 525 reciprocates the regenerator piston 520 with respect to the cold well tube 515 through a link 530. When the regenerator piston 520 is at the top of its motion cycle, a small volume at the sealed end of the cold well tube 515 provides the expansion space 532 in which an isothermic expansion of the refrigeration gas inside the cold well occurs.

[0044]A c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com