Modified activated carbon as well as preparation method and application thereof

A technology of activated carbon and modification, which is applied in the field of modified activated carbon and its preparation, which can solve the problems of low plasticity of activated carbon and difficult to overcome, and achieve the effects of improving catalytic activity, increasing load, and enhancing bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

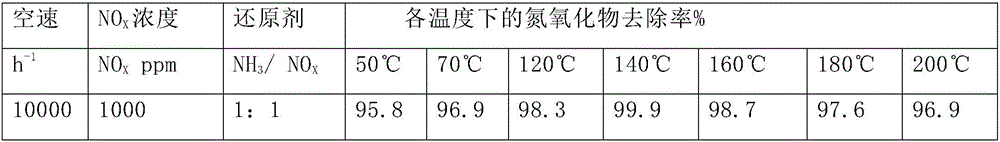

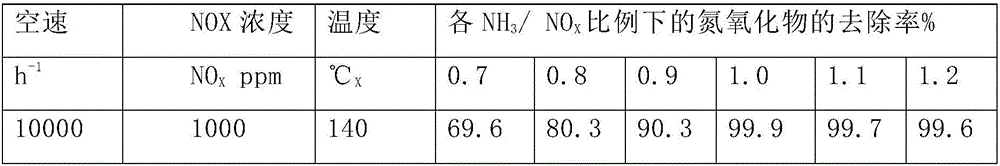

Examples

Embodiment 1

[0045] (1) Preparation of modified activated carbon

[0046] 1) Add coconut shell activated carbon to an aqueous solution of nitric acid with a content of 20% by weight and treat the activated carbon at 50°C for 6h, wash the treated activated carbon with deionized water and dry at 90°C for 8h for later use , wherein the mass volume ratio of the gac and the nitric acid aqueous solution is 1:8;

[0047] 2) Adding 10% manganese nitrate aqueous solution and Polyethylene Glycol 1000 to the activated carbon obtained in step 1), after soaking for 3 hours, enter the electric furnace protected by nitrogen for activation, the activation time is 5 hours, and the activation temperature is 400 ℃, to obtain pre-modified activated carbon, wherein the add-on of polyethylene glycol 1000 is 1% of the manganese nitrate aqueous solution weight;

[0048] 3) adding the pre-modified activated carbon obtained in step 2) into a 10% alkali solution by weight, soaking for 3 hours, and then entering int...

Embodiment 2

[0066] (1) Preparation of modified activated carbon

[0067] 1) Add coconut shell activated carbon to an aqueous solution of nitric acid with a content of 20% by weight and treat the activated carbon at 50°C for 6h, wash the treated activated carbon with deionized water and dry at 90°C for 8h for later use , wherein the mass volume ratio of the gac and the nitric acid aqueous solution is 1:8;

[0068] 2) Add manganese nitrate aqueous solution and Polyethylene Glycol 1000 that are 5% by weight to the activated carbon obtained in step 1), after soaking for 4 hours, enter into an electric furnace protected by nitrogen to activate, the activation time is 5 hours, and the activation temperature is 350 ℃, to obtain pre-modified activated carbon, wherein the add-on of polyethylene glycol 1000 is 0.5% of the manganese nitrate aqueous solution weight;

[0069] 3) adding the pre-modified activated carbon obtained in step 2) into an 8% alkali solution by weight, soaking for 3 hours, and...

Embodiment 3

[0087] (1) Preparation of modified activated carbon

[0088] 1) Add coconut shell activated carbon to an aqueous solution of nitric acid with a content of 20% by weight and treat the activated carbon at 50°C for 6h, wash the treated activated carbon with deionized water and dry at 90°C for 8h for later use , wherein the mass volume ratio of the gac and the nitric acid aqueous solution is 1:8;

[0089] 2) Adding the manganese nitrate aqueous solution and Polyethylene Glycol 1000 that the weight percent content is 15% to the gac obtained in step 1), after soaking for 6 hours, enter the electric furnace protected by nitrogen for activation, the activation time is 5 hours, and the activation temperature is 450 ℃, to obtain pre-modified activated carbon, wherein the add-on of Polyethylene Glycol 1000 is 4% of manganese nitrate aqueous solution weight;

[0090] 3) adding the pre-modified activated carbon obtained in step 2) into a 15% alkali solution by weight, soaking for 4 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com