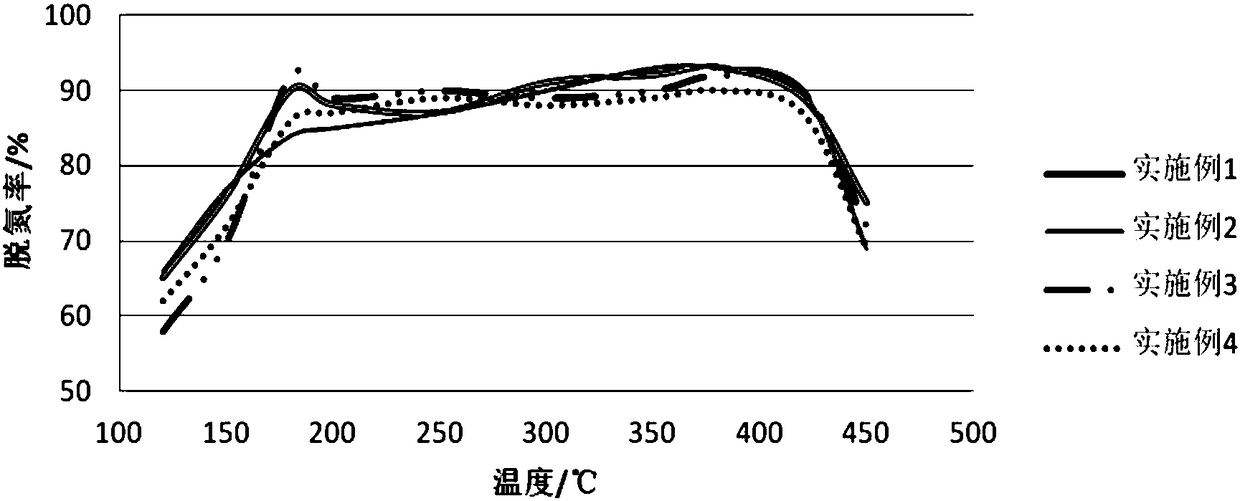

Titanium and molybdenum compound powder for low-temperature SCR (Selective Catalytic Reduction) denitration and preparation method thereof

A composite powder and denitrification technology, applied in the field of denitrification catalysts, can solve the problems of unsatisfactory medium and low temperature denitrification rate, complicated process, high cost, etc., and achieve the effect of low cost, uniform particle size distribution and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

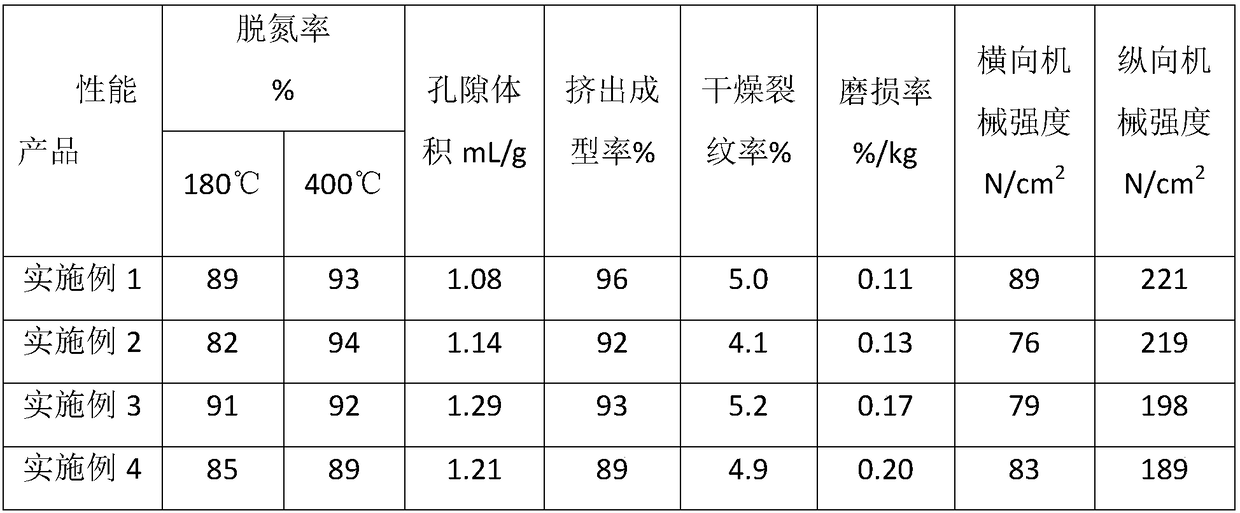

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing titanium-molybdenum composite powder for SCR denitrification at medium and low temperatures, the steps are as follows:

[0034] a. The raw material metatitanic acid is beaten and dispersed in deionized water or ultrapure water, and adjusted to a slurry with a mass fraction of 10% to 20% in terms of titanium dioxide;

[0035] b. adding ammonia water to the slurry treated in step a to adjust the pH value to 7.5-9.0;

[0036] c. filtering and dehydrating the slurry obtained after the treatment in step b to obtain block filter cake;

[0037] d. Ammonium heptamolybdate (using MoO 3 Content ≥ 80%) is dissolved in deionized water to obtain ammonium heptamolybdate solution;

[0038] e. the solution obtained in step d is divided into MoO in the final product 3 The ratio of 3% to 10% content is evenly sprayed on the filter cake by spraying, and calcined at 150°C to 520°C for 5h to 8h;

[0039] f. After the calcined kiln...

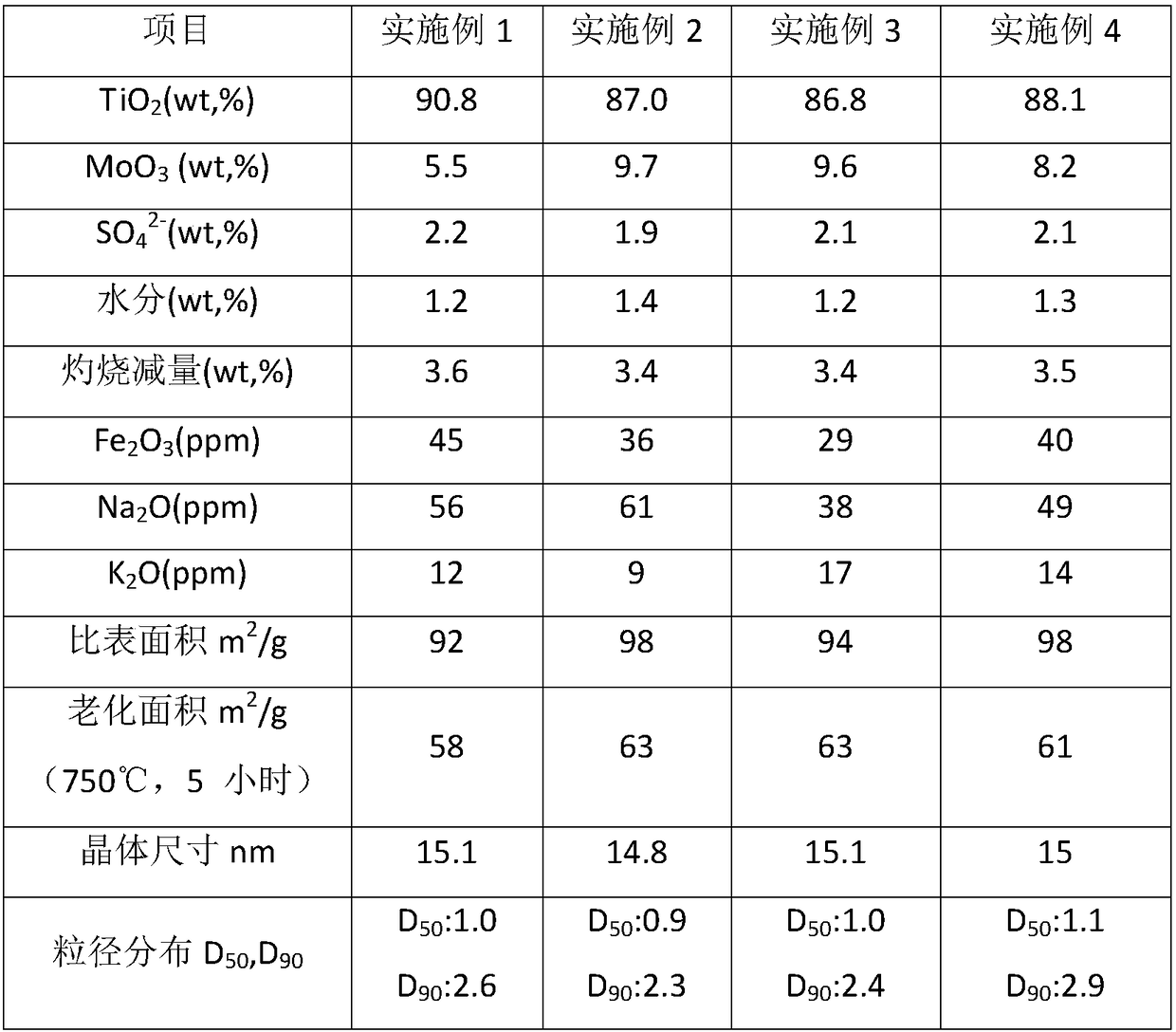

Embodiment 1

[0054] Weigh 38Kg metatitanic acid (TiO 2 Content 26.3%), after classifying by swirl, add it to the reactor with stirring device, add a certain amount of deionized water, adjust the slurry concentration to 15wt% in terms of titanium dioxide; after stirring evenly, add ammonia water to the slurry to adjust the pH value To 8.2; press filtration obtains titanium dioxide massfraction after fully stirring and is the massive metatitanic acid filter cake of 47.84%; With 720g ammonium heptamolybdate (as MoO 3 82% total content) dissolved in 2400ml of water, stirred evenly and evenly sprayed on the above-mentioned metatitanic acid filter cake by spraying method; enter the rotary kiln for calcination, calcination at 250°C for 2h, calcination at 350°C for 1.5h, and calcination at 420°C for 1h , calcined at 485°C for 1 h; the calcined kiln material obtained by calcination was crushed with a pulverizer to prepare TiO 2 -MoO 3 Composite powder products.

Embodiment 2

[0056] Take by weighing 38.3Kg metatitanic acid (TiO 2 Content 26.1%), after classifying by swirl, add it to the reactor with stirring device, add a certain amount of deionized water, adjust the concentration of the slurry to 14wt% in terms of titanium dioxide; after stirring evenly, add ammonia water to the slurry to adjust the pH value to 8.8; after fully stirring and filtering, the filter material obtained by filtering is block metatitanic acid, and the mass fraction of titanium dioxide in the filter cake is 48.13%; Spray evenly on the filter cake; enter the rotary kiln for calcination, calcine at 250°C for 2 hours, calcine at 350°C for 1.5h, calcine at 420°C for 1 hour, and calcine at 485°C for 1 hour; grind the calcined kiln material obtained by calcination with a pulverizer to prepare a powder TiO 2 -MoO 3 Composite powder products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com