Heat diffusing device and method of producing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

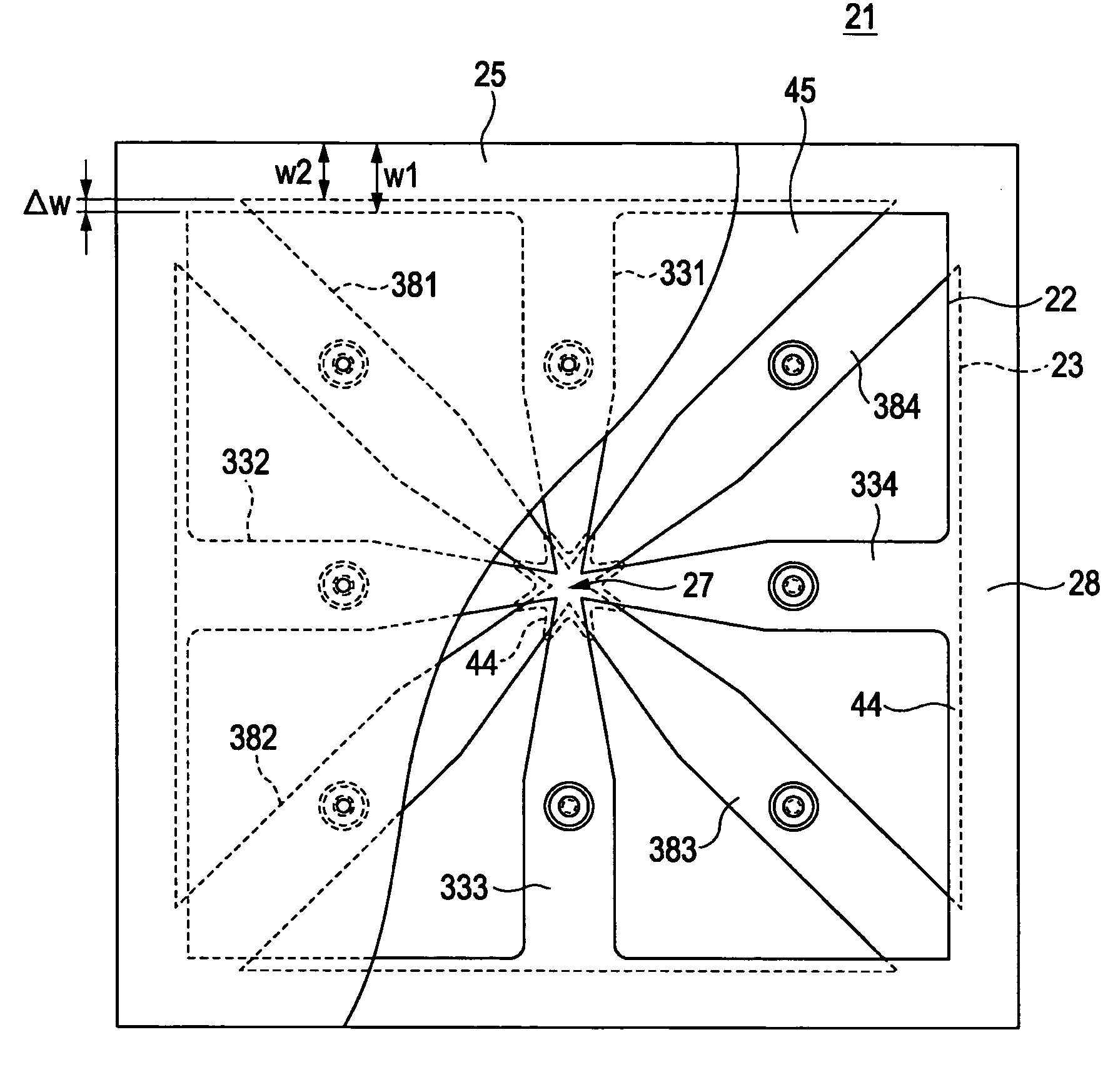

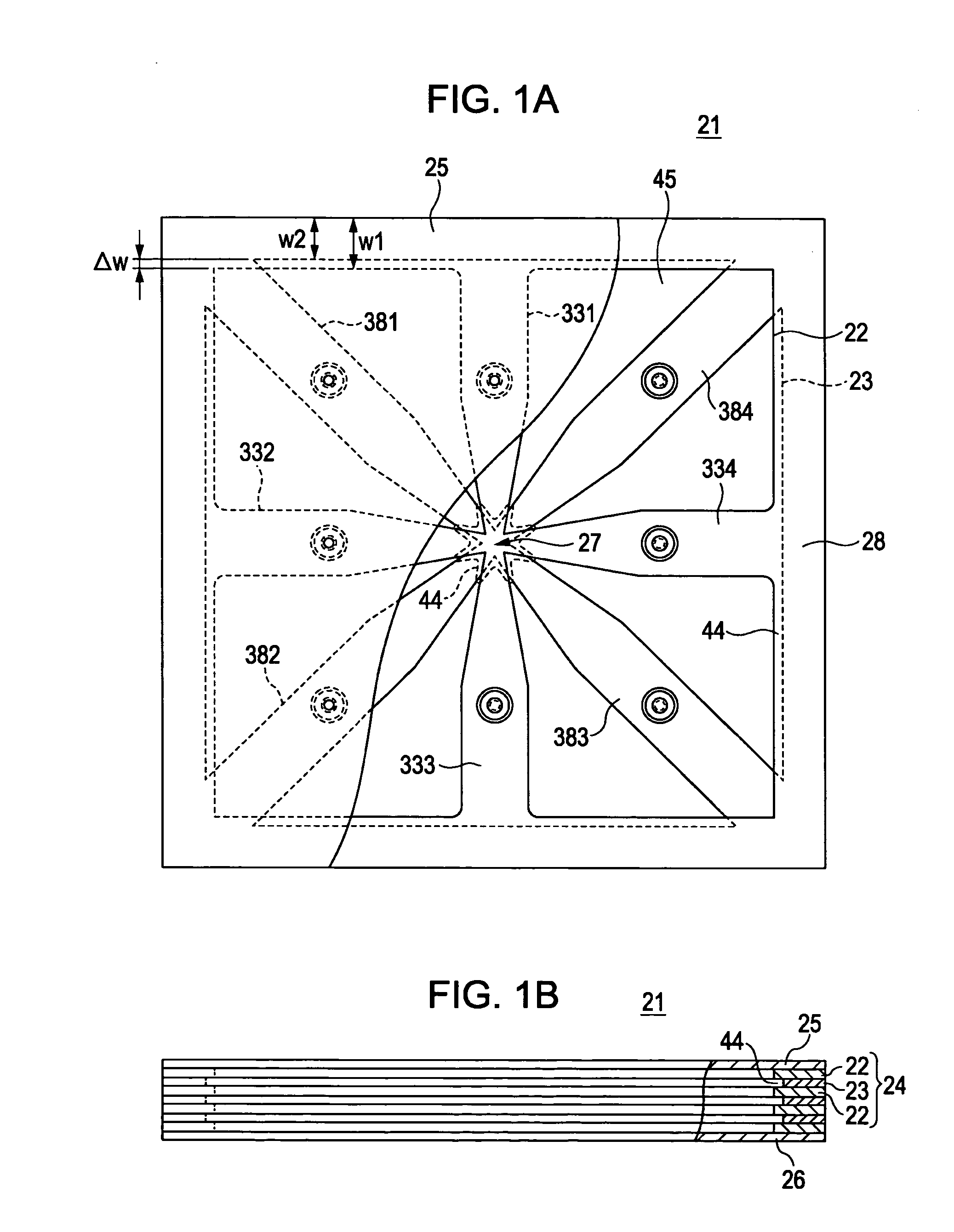

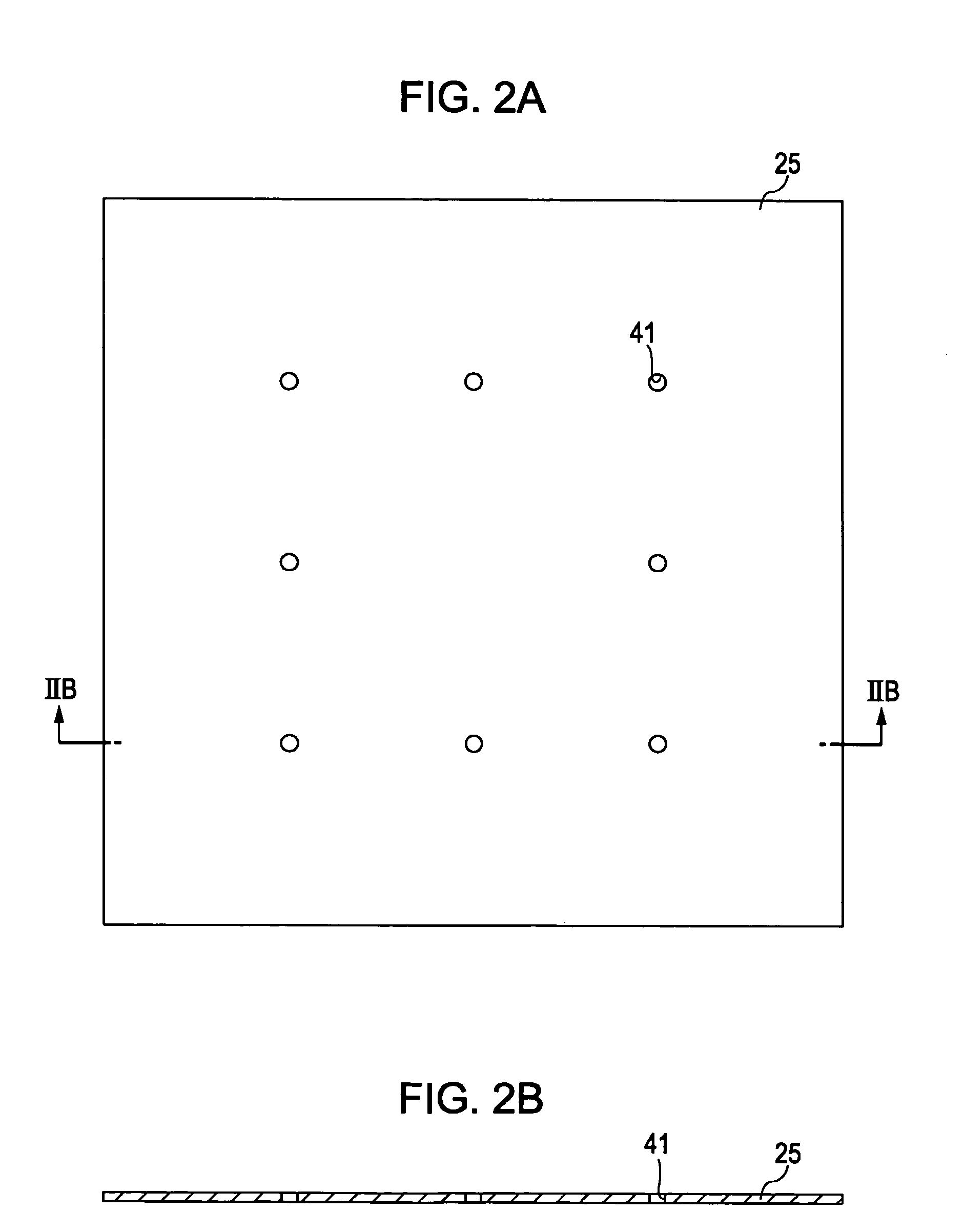

[0040]FIGS. 1 to 5 illustrate a heat diffusing device and a method of producing the same according to the present invention. As shown in FIGS. 1A and 1B, a heat diffusing device 21 according to the embodiment includes a laminated body 24 and sealing metallic plates 25 and 26. The laminated body 24 includes first metallic thin plates 22 and second metallic thin plates 23, which are alternately laminated, and which have rectangular contour shapes, that is, rectangular contour shapes of the same size in the embodiment, as viewed from above. The dimensions of the second metallic thin plates 23 differ from those of the first metallic thin plates 22. The sealing metallic thin plates 25 and 26 seal the top and bottom of the laminated body 24, respectively. The first and second metallic thin plates 22 and 23 have the same film thickness. The upper and lower sealing metallic thin plates 25 and 26 also have the same film thickness.

[0041]As shown in FIGS. 3A and 3B, each first metallic thin pl...

second embodiment

[0058]FIGS. 12 to 17 show a heat diffusing device and a method of producing the same according to the present invention. As shown in FIGS. 12 and 13, a heat diffusing device 61 according to the embodiment includes a laminated body 64 and sealing metallic thin plates 65 and 66 that seal the upper and lower sides of the laminated body 64. In the laminated body 64, first metallic thin plates 62 and second metallic thin plates 63 are alternately laminated, and have rectangular shapes in which a long side of a contour shape is sufficiently longer than a short side of the contour shape as viewed from above. The dimensions of each second metallic thin plate 63 differ from those of each first metallic thin plate 62. The first and second metallic thin plates 62 and 63 have the same thickness. The upper sealing metallic thin plate 65 and the lower sealing metallic thin plate 66 also have the same thickness.

[0059]As shown in FIGS. 14A to 14C, each first metallic thin plate 62 is formed into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com