Circuit board structure with concave conductive cylinders and method for fabricating the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

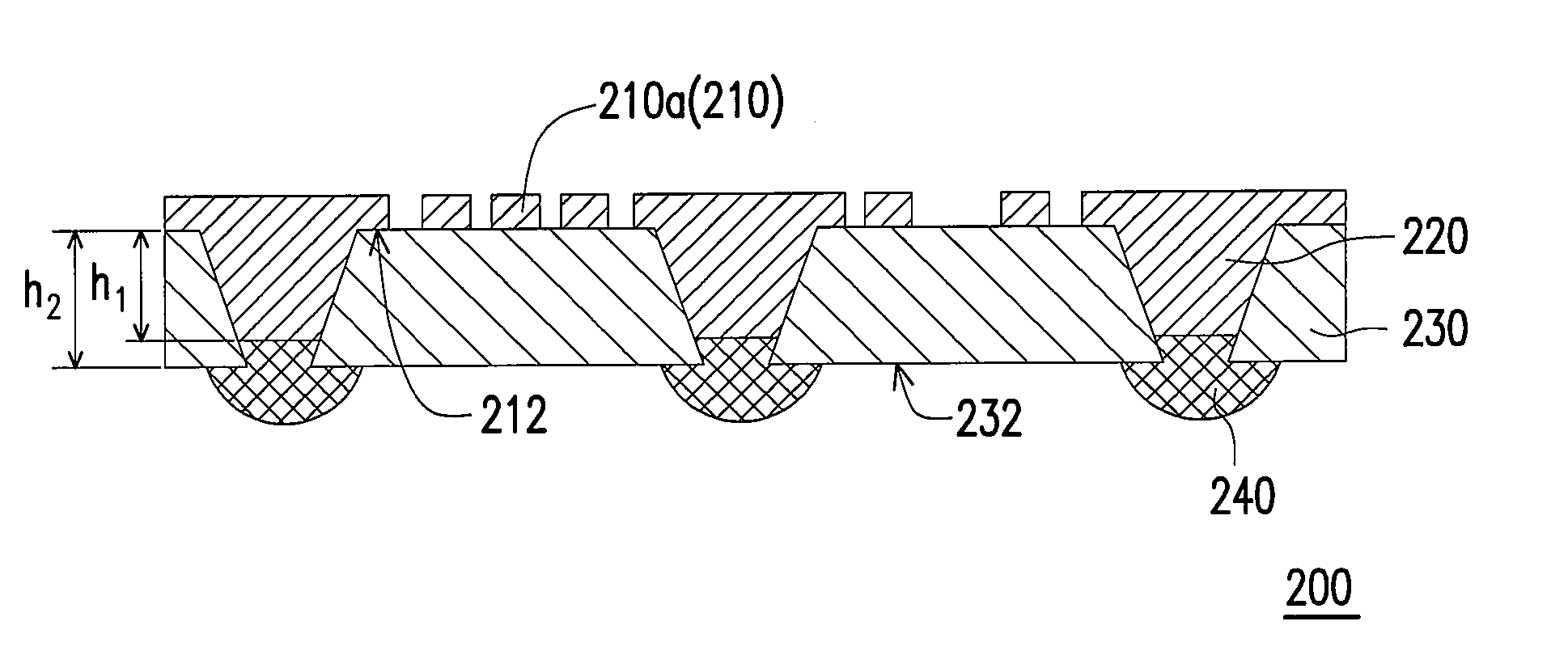

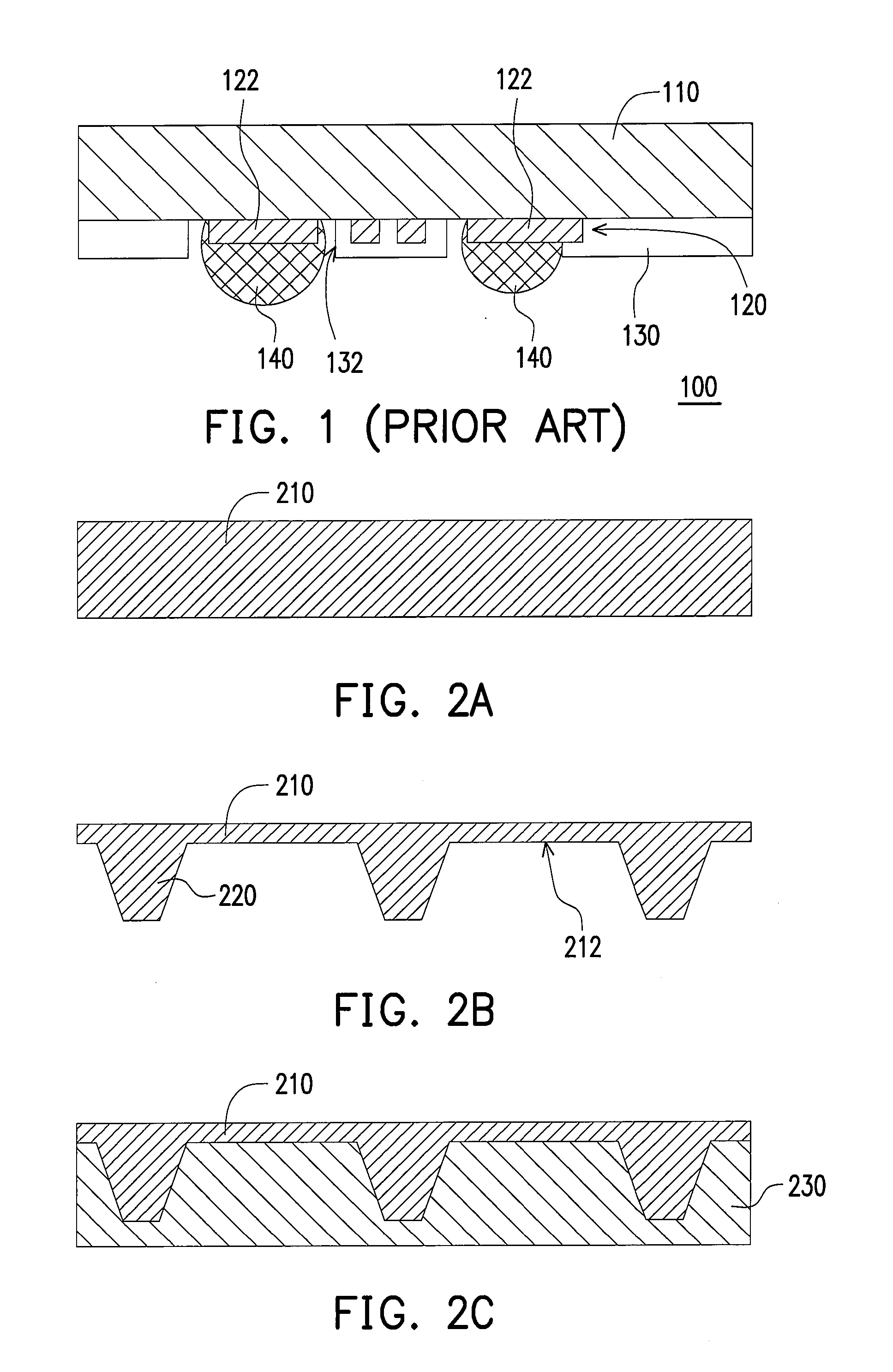

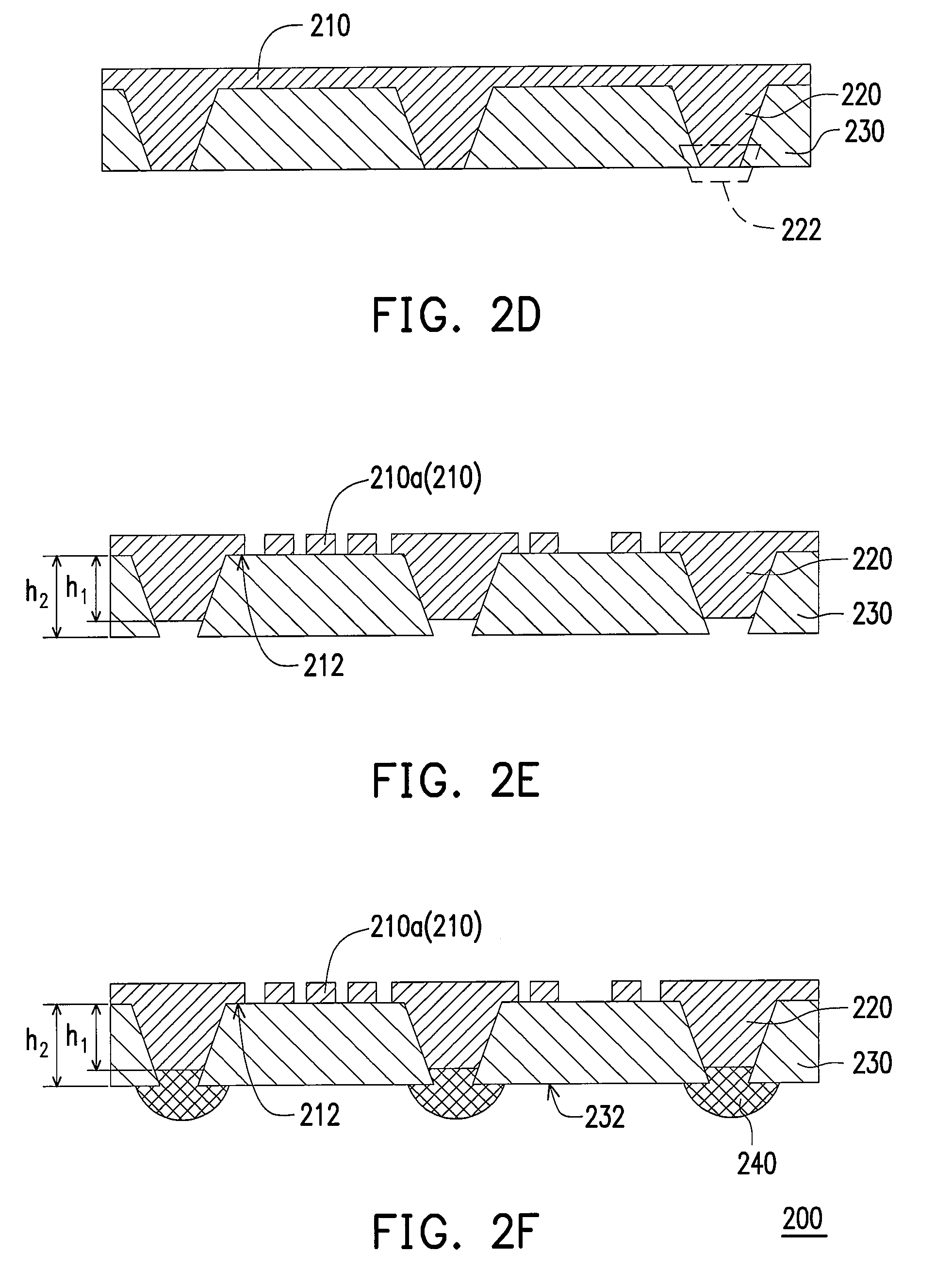

[0028]FIG. 2A˜FIG. 2F are flow diagrams of fabricating the circuit board structure with concave conductive cylinders of the first embodiment of the present invention. With reference to FIG. 2A, first a conductive layer 210 is provided, the conductive layer 210 for example is a metal layer, the material of the conductive layer 210 may be copper. Next, with reference to FIG. 2B, partially etching the conductive layer 210 is conducted, so that a plurality of conductive cylinders 220 are formed on the surface 212 of the conductive layer. In another embodiment which is not shown, the conductive cylinders 220 may also be formed on the surface 212 of the conductive layer 210 through forming bumps using welding wire machine or through other appropriate method.

[0029]Next, with reference to FIG. 2C, a dielectric layer 230 is formed on the surface 212 of the conductive layer 210 on which the conductive cylinders 220 are formed. The method of forming the dielectric layer 230 on the conductive l...

second embodiment

[0034]FIG. 3A˜FIG. 3F are diagrams of the flow of fabricating the circuit board structure with concave conductive cylinders of the second embodiment of the present invention. The present embodiment is similar to the previous embodiment, the only difference is that: in the previous embodiment, the dielectric layer 230 is formed after the conductive cylinders 220 are formed; while in the present embodiment, the dielectric layer 320 is formed before the conductive cylinders 330 are formed. Refer the following descriptions for the flow detail, the similarities thereof will not be repeated.

[0035]With reference to FIG. 3A, a conductive layer 310 which has a surface 312 is formed. Next, with reference to FIG. 3B, by using laminating method or printing method or the alike, a dielectric layer 320 is formed on the surface 312 of the conductive layer 310 on which the conductive cylinders 330 are formed. Further next, with reference to FIG. 3C, a plurality of vias 322 are formed in the dielectr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical conductor | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com