LOW k POROUS SiCOH DIELECTRIC AND INTEGRATION WITH POST FILM FORMATION TREATMENT

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

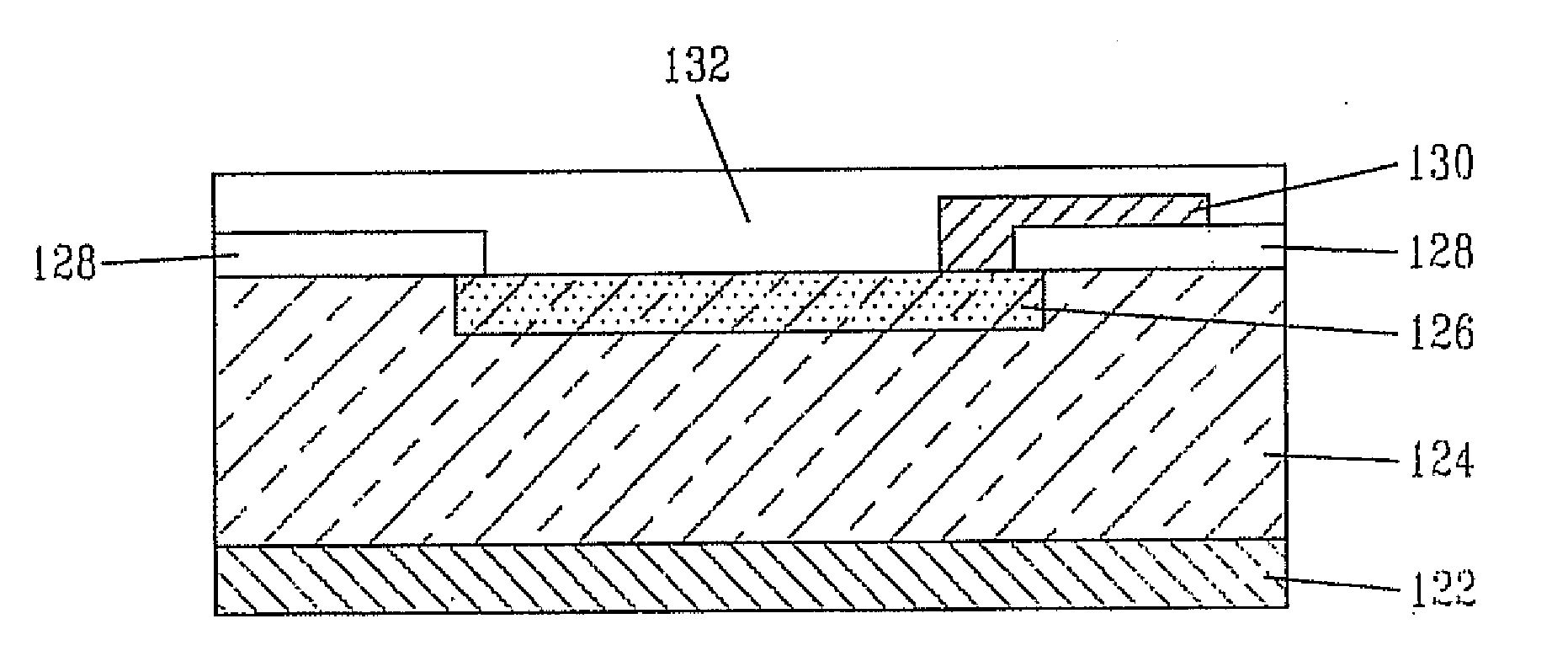

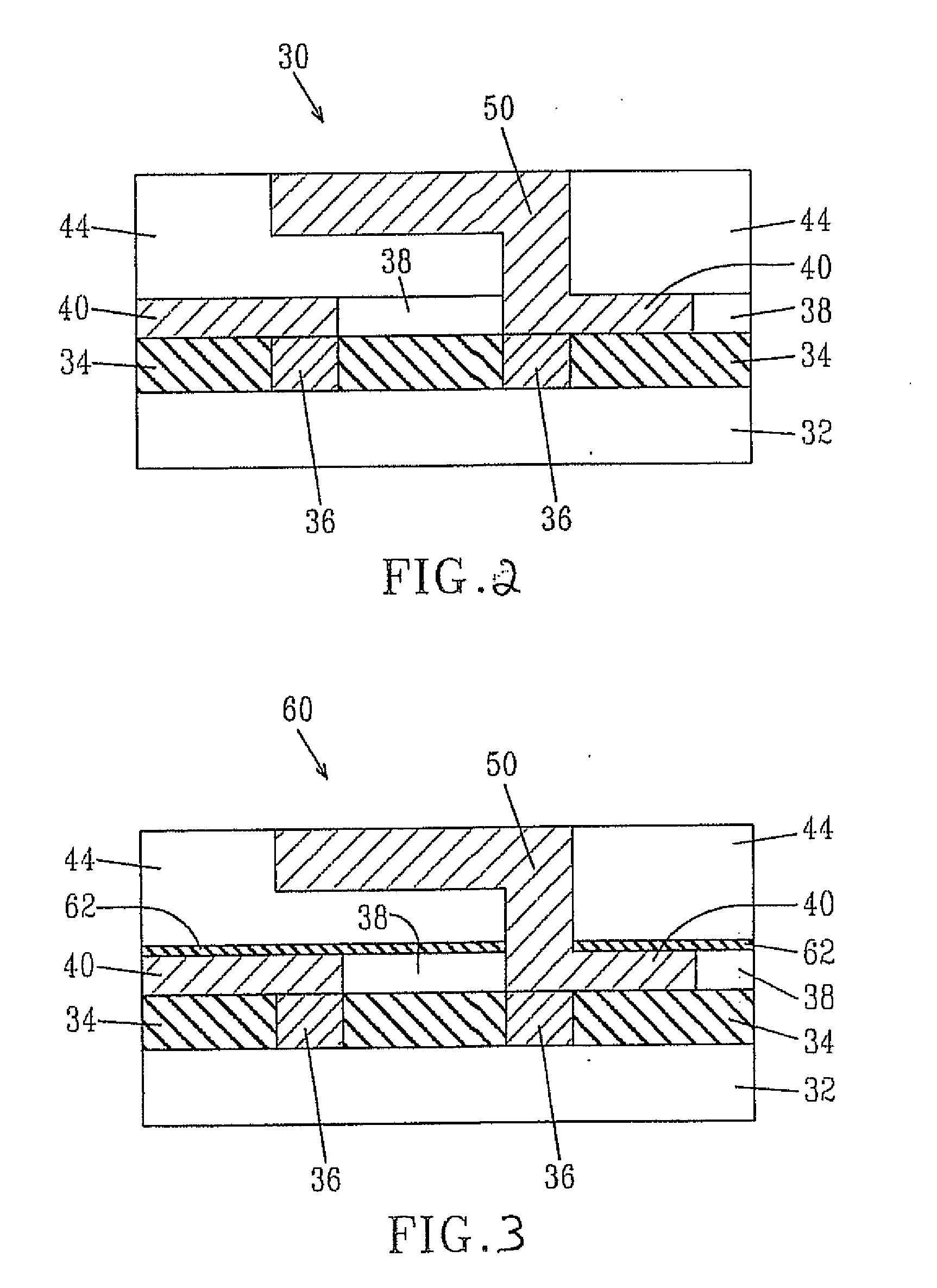

[0039]The present invention, which describes a p-SiCOH dielectric film having a reduced content of Si—OH and Si—H bondings, and increased —(CHx)— bondings within the pores and on the surface of the film, a method of fabricating the same and electronic structures containing the inventive p-SiCOH dielectric film, will now be described in greater detail.

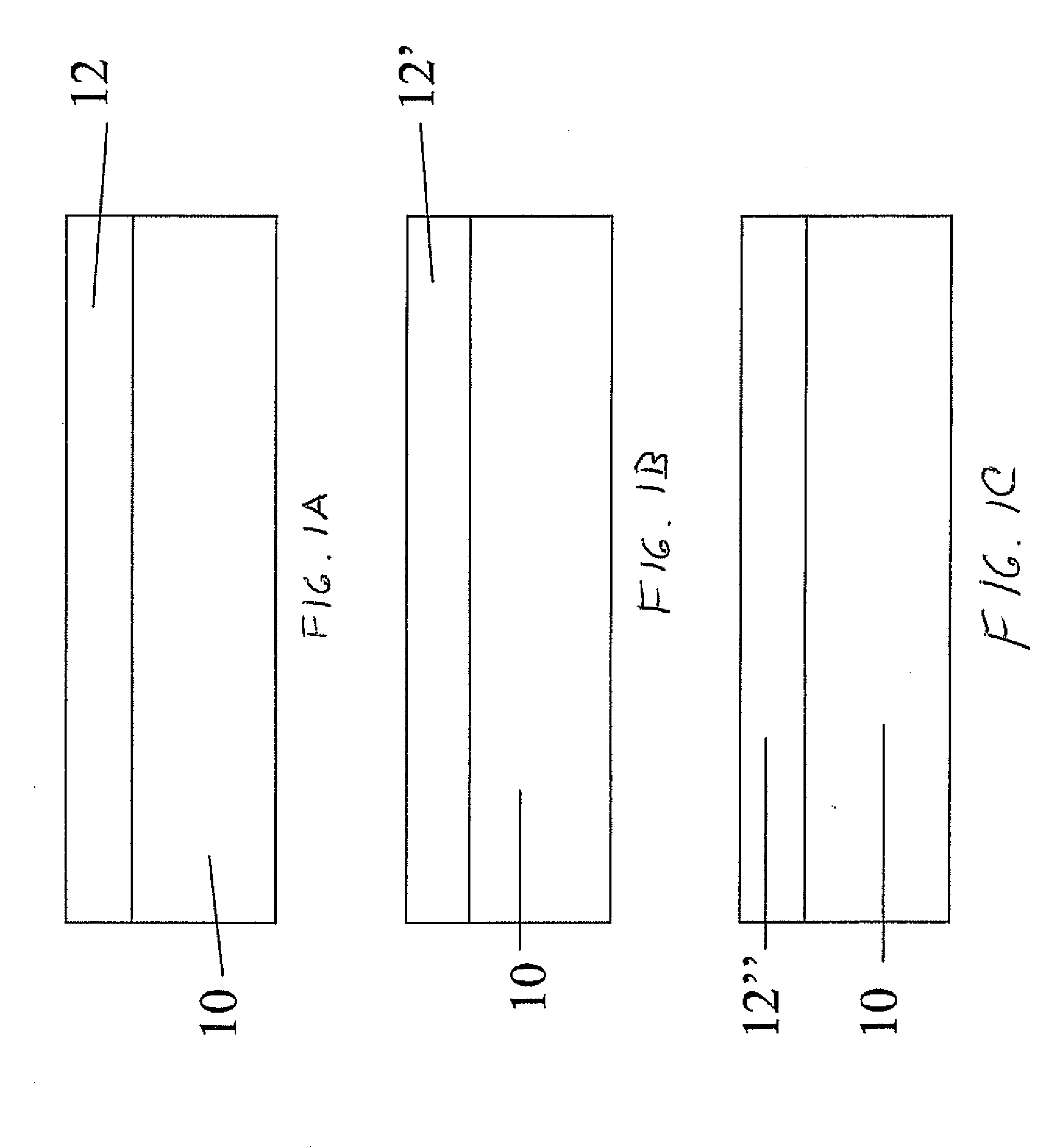

[0040]In accordance with the method of the present invention, a SiCOH dielectric film 12 is formed on a surface of a substrate 10 such as shown, for example, in FIG. 1A. The term “substrate” when used in conjunction with substrate 10 includes, a semiconducting material, an insulating material, a conductive material or any combination thereof, including multilayered structures. Thus, for example, substrate 10 may be a semiconducting material such as Si, SiGe, SiGeC, SiC, GaAs, InAs, InP and other III / V or III / VI compound semiconductors. The semiconductor substrate 10 may also include a layered substrate such as, for example, Si / SiGe, Si / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Dielectric polarization enthalpy | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com