Heat exchange reformer unit and reformer system

a heat exchange and reformer technology, applied in the direction of combustible gas production, sustainable manufacturing/processing, chemical/physical/physicochemical processes, etc., can solve the problem of limiting the improvement of the reforming efficiency of the system, and achieve excellent heat exchange efficiency between the heating section and the reforming section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

third embodiment

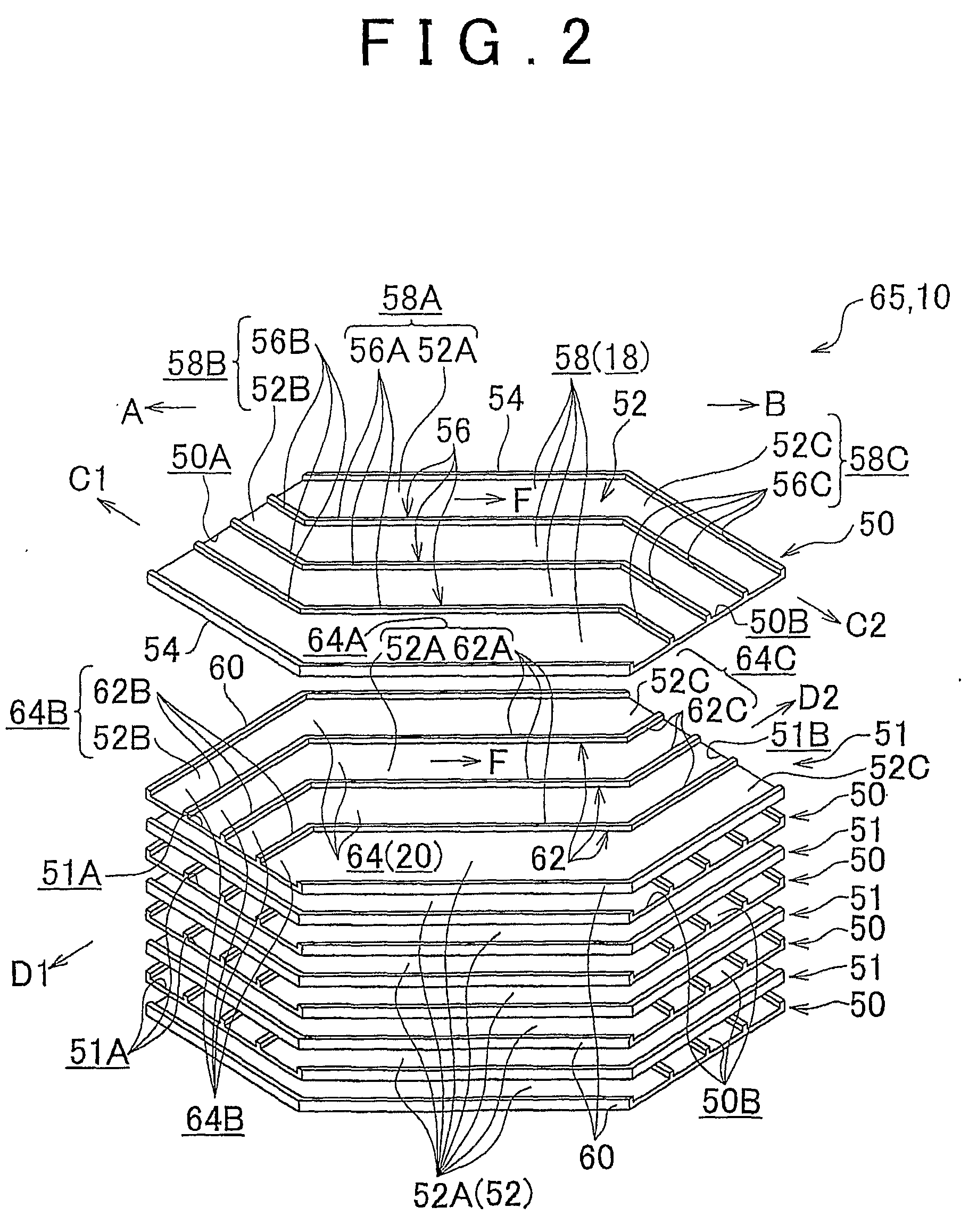

[0149]FIG. 15A shows a heat exchange reformer unit 80 according to a third embodiment in a front view in section corresponding to FIG. 8A. As shown in FIG. 15A, the heat exchange reformer unit 80 differs from the heat exchange reformer unit 10, which includes the multilayer core unit 65 in which two layers of the reforming passages 18 are stacked per one layer of the combustion passage 20, in that the heat exchange reformer unit 80 includes a multilayer core unit 82 in which three unit plate members 50 (three layers of the reforming passages 18) are stacked per one unit plate member 51 (one layer of the combustion passage 20).

[0150]Specifically, in the multilayer core unit 82, three layers of the reforming passages 18 are disposed between a pair of the combustion passages 20, as shown in FIG. 15B, by stacking the units, in each of which three unit plate members 50 are stacked on the same side of one unit plate member 51. Accordingly, in the multilayer core unit 82, one layer of the ...

fourth embodiment

[0155]FIG. 16A shows a front view in section of a heat exchange reformer unit 90 according to a fourth embodiment. FIG. 16B shows a plan view of the reforming passage 18 (combustion passage 20) constituting the heat exchange reformer unit 90. As shown in these figures, the heat exchange reformer unit 90 differs from the heat exchange reformer unit 80 in including a multilayer core unit 94 in which such unit plate members 50 and 51 as described below are stacked. Specifically, in the unit plate member 50, heat transfer-supporting ribs 92, which constitutes heat transfer-promoting portions, are provided in a standing condition between the end portions of the standing walls 56 on the gas inlet 50A-side thereof, and in unit plate members 51, heat transfer-supporting ribs 92, which constitutes heat transfer-promoting portions, are provided in a standing condition between the end portions of the standing walls 62 on the gas inlet 51A-side thereof.

[0156]In the fourth embodiment, the heat t...

fifth embodiment

[0160]FIG. 19A shows a heat exchange reformer unit 100 according to a fifth embodiment in a front view in section. FIG. 19B shows the reforming passages 18 (combustion passages 20) constituting the heat exchange reformer unit 100 in a plan view. As shown in these figures, the heat exchange reformer unit 100 differs from the heat exchange reformer unit 80 in including a multilayer core unit 104 in which such unit plate members 50 and 51 as described below are stacked. Specifically, in the unit plate members 50 and 51, end portions of the standing walls 56 on the gas inlet 50A-side, and end portions of the standing walls 62 on the gas inlet 51A-side are formed into heat transfer-supporting thick portions 102 as heat transfer-promoting portions, which are thicker than the remaining portions of the standing walls 56 and 62.

[0161]The heat transfer-supporting thick portions 102 are set substantially corresponding to the reaction field in which the combustion reactions mainly occur in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| total volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com