Shock absorber

a technology of shock absorber and side buffer, which is applied in the direction of draw-gear, window arrangement, transportation and packaging, etc., can solve the problems of the shock absorbance provided by the side buffer no longer being integrated into the energy-absorbing concept of the vehicle, and the damage to the hull of the ship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

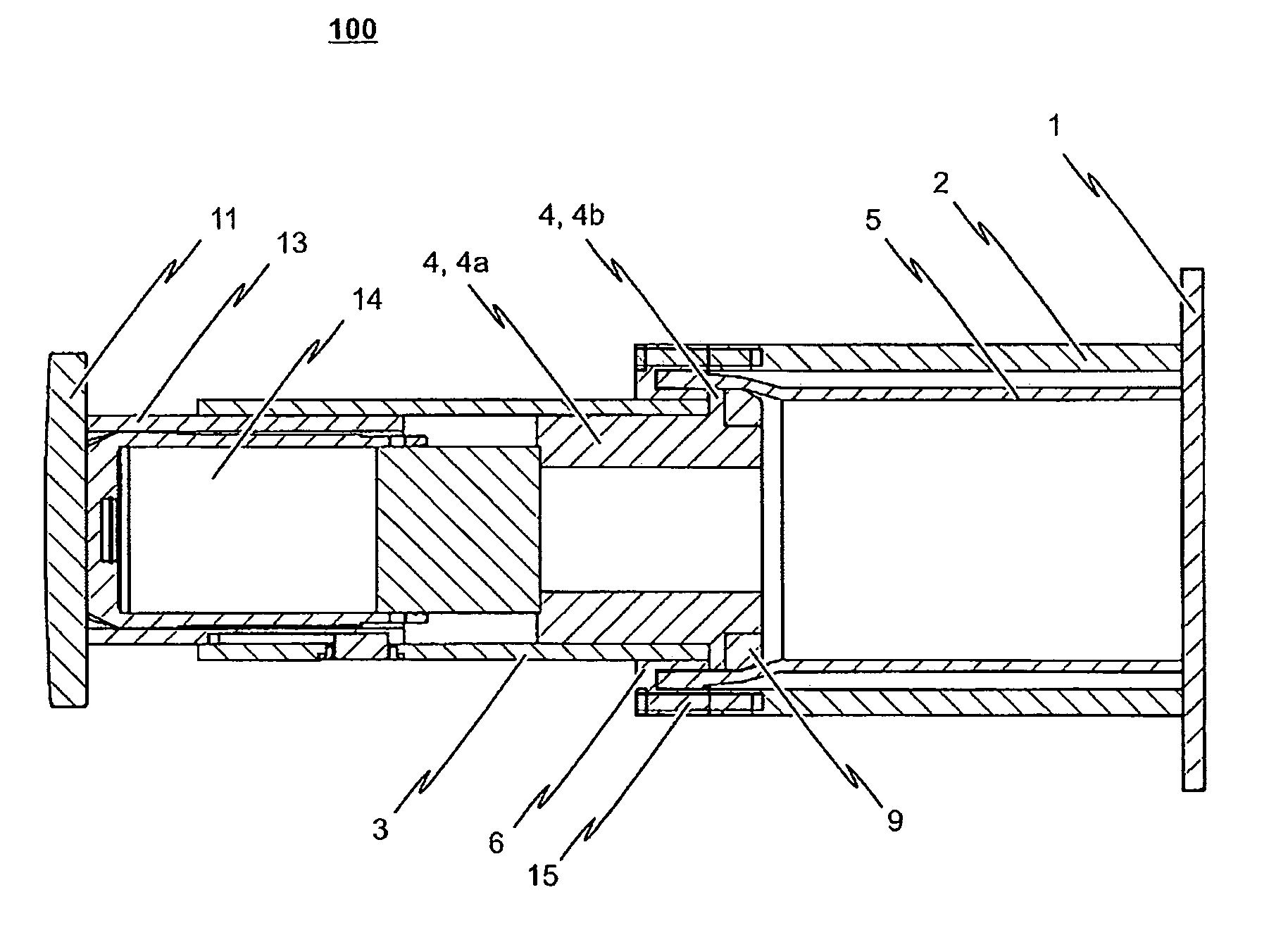

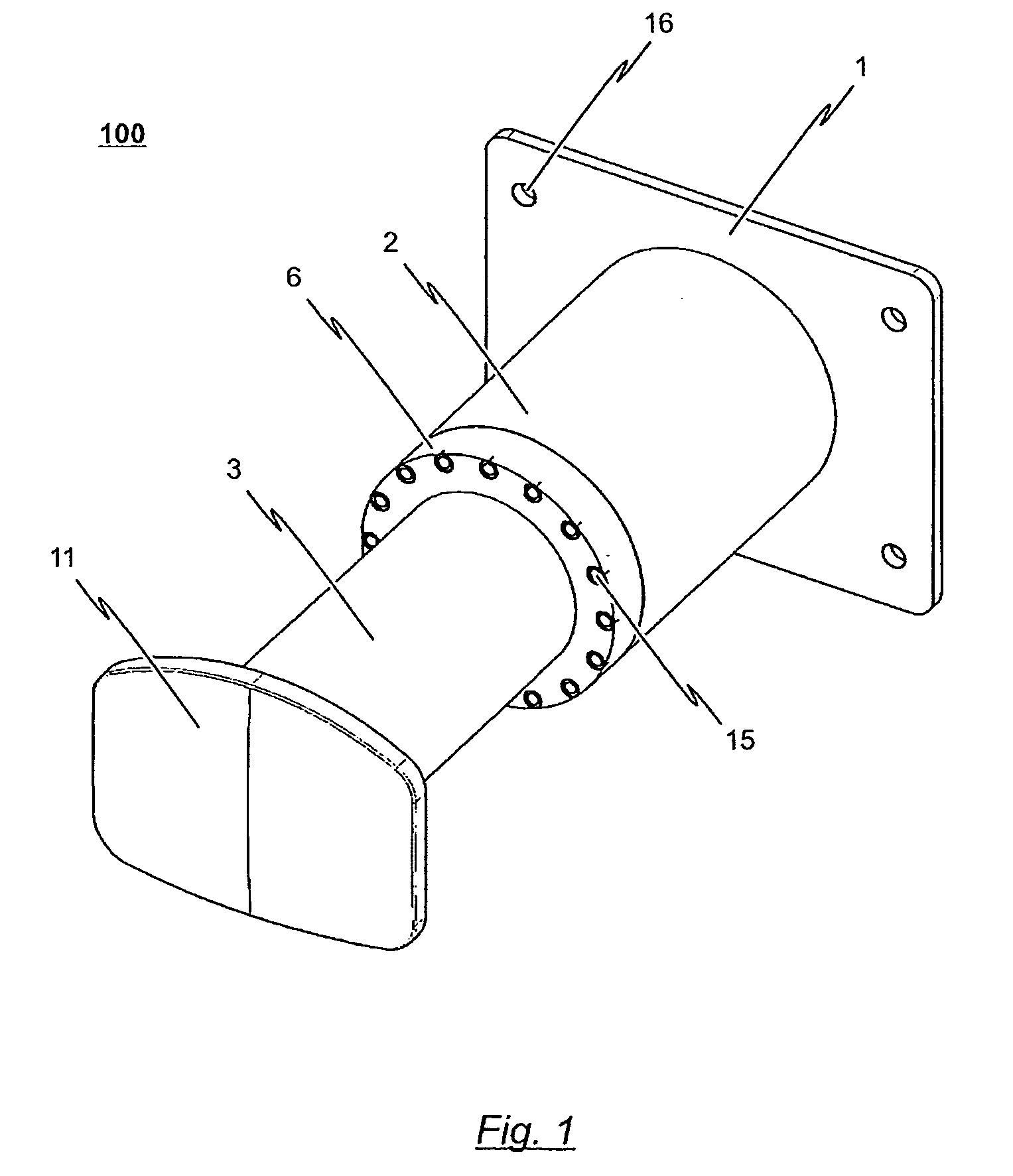

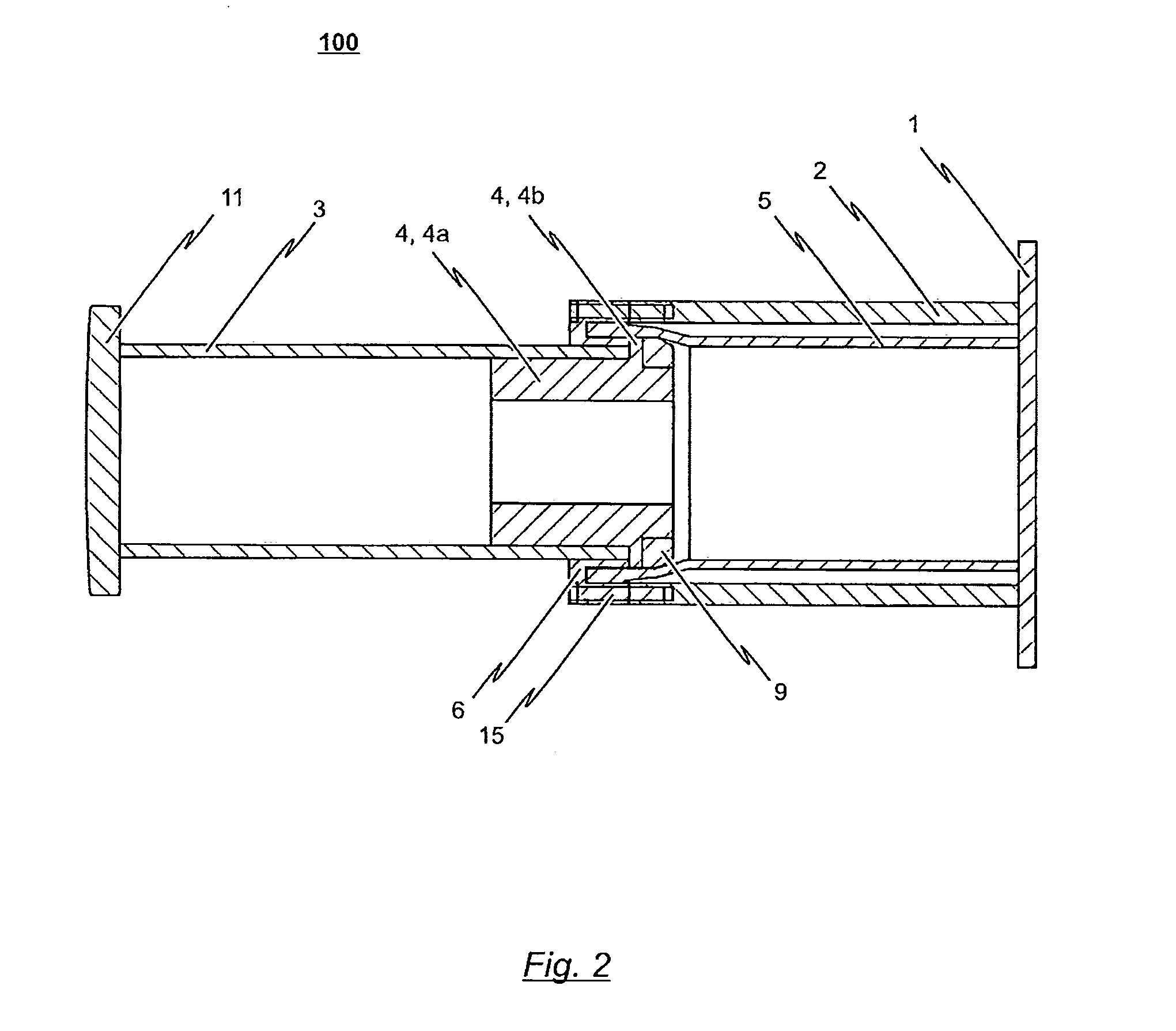

[0075]The shock absorber 100 in accordance with the first preferred embodiment is suitable as an irreversible shock-absorbing stage which, additionally to any given damping elements (such as e.g. side buffers) or energy-absorbing units there may be, can be mounted as one complete exchangeable modular unit to a support frame or the undercarriage of, for example, a railcar body. To this end, the shock absorber 100 in accordance with the first embodiment comprises a base plate 1 configured as a flange which can be mounted for example with bolts to the (not explicitly shown) supporting structure. Throughholes 16 are thereby preferably provided in base plate 1 through which the bolts used to fix the shock absorber 100 can be guided.

[0076]The shock absorber 100 according to the first embodiment consists of a support frame 2 which is fixedly connected to the base plate 1. In detail, the support frame 2 of the embodiment depicted is configured as a tube section of circular cross-section. A ...

second embodiment

[0092]the inventive shock absorber 100 provides a complete exchangeable module which can be mounted for example to a supporting structure for a railcar body. This is thus a shock absorber which, due to the integration of the buffer device 12, also exhibits effective damping properties during normal vehicle operation. The buffer device integrated in shock absorber 100 can for example serve as a regeneratively-designed shock absorber, in which the impact forces occurring for example between the individual car bodies of a multi-member vehicle during normal operation of the vehicle can be absorbed or damped. When the operating load of the regeneratively-designed damping element 14 of buffer device 12 integrated in shock absorber 100 is exceeded, however, the energy-absorbing unit (deformation tube 5) of the shock absorber 100 downstream the buffer device 12 is activated, whereby the impact energy is converted into the work of deformation and heat by a defined plastic deformation of said...

third embodiment

[0095]To this end, the shock absorber 100 comprises a base plate 1, by means of which the shock absorber 100 can be detachably affixed to the supporting structure. Conceivable hereto would be for example providing throughholes 16 in base plate 1 to receive screws, pins, bolts, etc. ultimately serving to fix the base plate 1 to the supporting structure.

[0096]Instead of throughholes 16, however, other solutions would also be conceivable as fixing means. For example, if due to structural design contingencies, base plate 1 can only be provided with a relatively small edge area in which there would not be enough space for the appropriate throughholes 16, respectively insufficient space for screws, bolts, etc. to be received in the throughholes 16, it would be suitable to weld or otherwise affix a nipple or the like to the rear side of base plate 1; i.e. the side of base plate 1 faced away from the support frame 2, wherein only this nipple serves to fix the shock absorber 100 to the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com