Refrigerant compressor

a refrigerant compressor and hermetically sealed technology, which is applied in the direction of machines/engines, rotary/oscillating piston pump components, liquid fuel engines, etc., can solve the problems of adverse effect on achieve the optimization of the efficiency of the refrigerant compressor, reduce heat transmission, and reduce efficiency loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

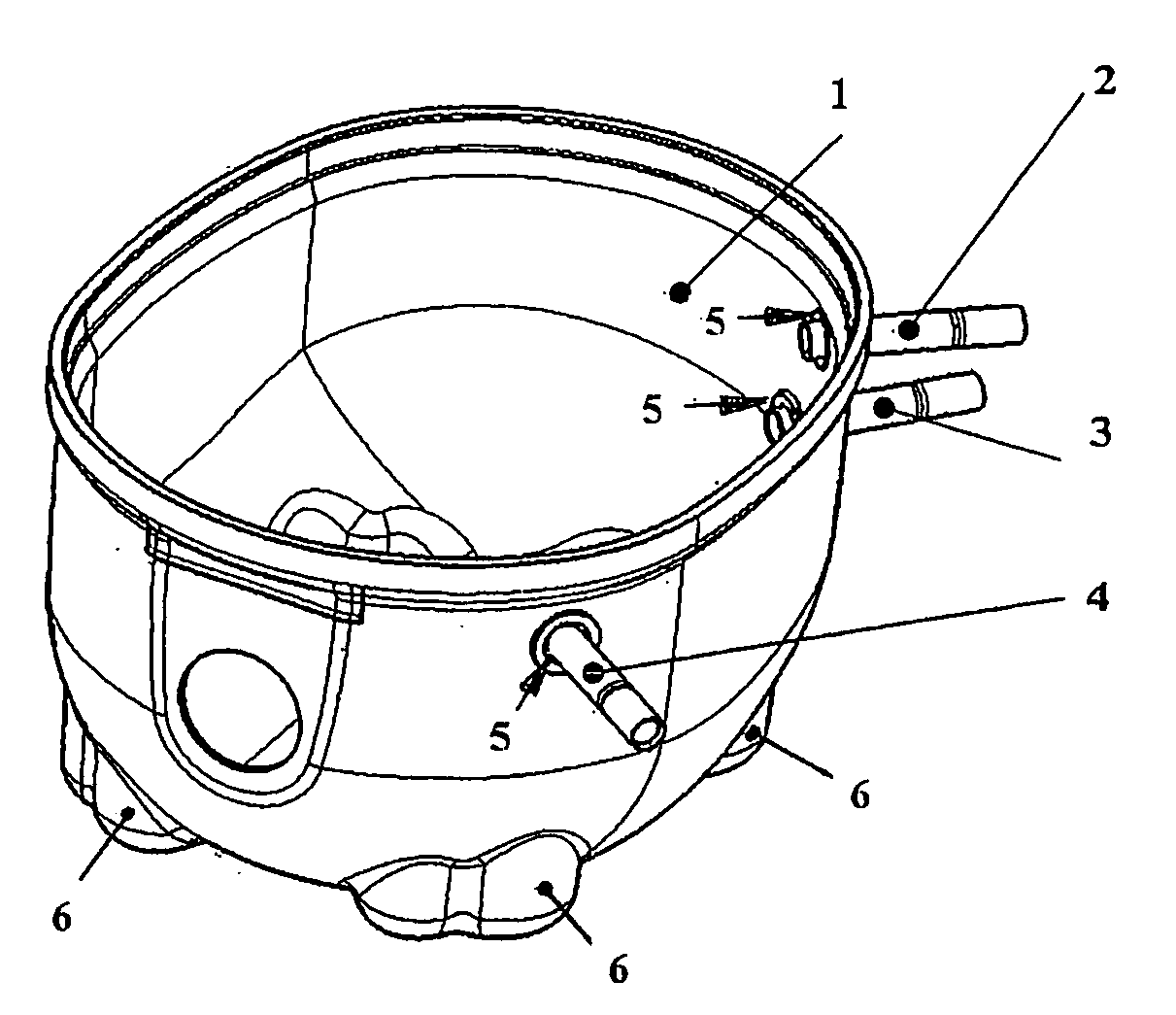

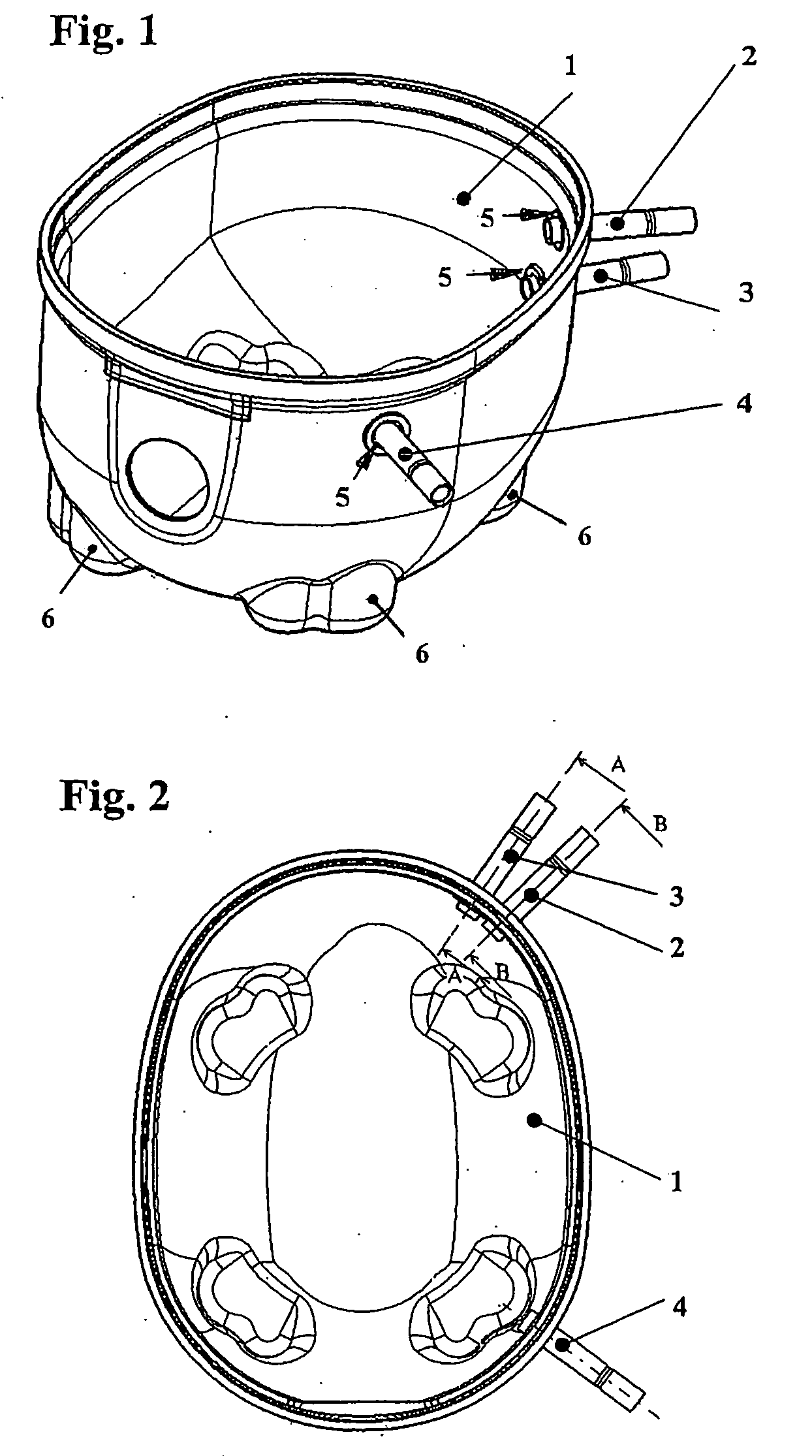

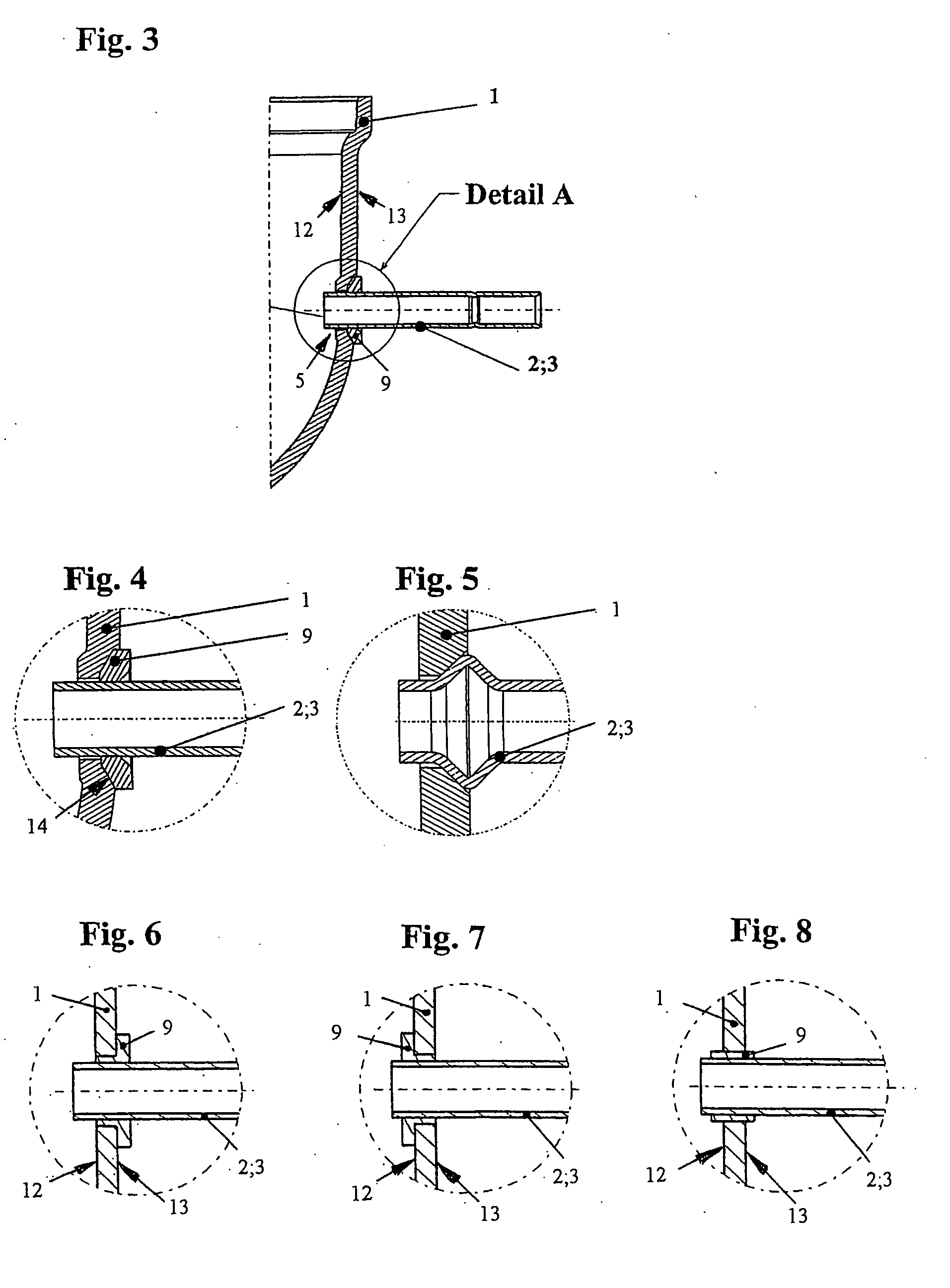

[0041]A refrigerant compressor comprises a hermetically sealed compressor housing 1, with a suction pipe 2, a pressure pipe 3 and a service pipe 4 opening into the same via connection openings 5.

[0042]A refrigerant flows via the suction tube 2 in the known manner to a piston-cylinder unit (not shown) which is arranged within the compressor housing 1 and in which a compression of the refrigerant occurs, with the pressure pipe 3 subsequently leading the compressed and therefore strongly heated refrigerant from the piston-cylinder unit out of the compressor housing 1 to a cooling circuit (also not shown) of a cooling space. The piston-cylinder unit is driven by an electromotor via a crankshaft, so that cooling space associated with the refrigerant compressor is continually cooled by means of the circulating refrigerant.

[0043]Compressor housing 1 comprises several standing elements 6 which are used to position the same on a floor space of a refrigerating device determined for this purpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com