Artificial hair and wig using the same

a technology of artificial hair and wig, applied in the field of artificial hair, can solve the problem of still having a rigidity for bending lower than natural hair, and achieve the effects of lowering the rigidity for bending, excellent appearance, and difficult to recogniz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0101]Explanation is next made in detail of examples of the present invention.

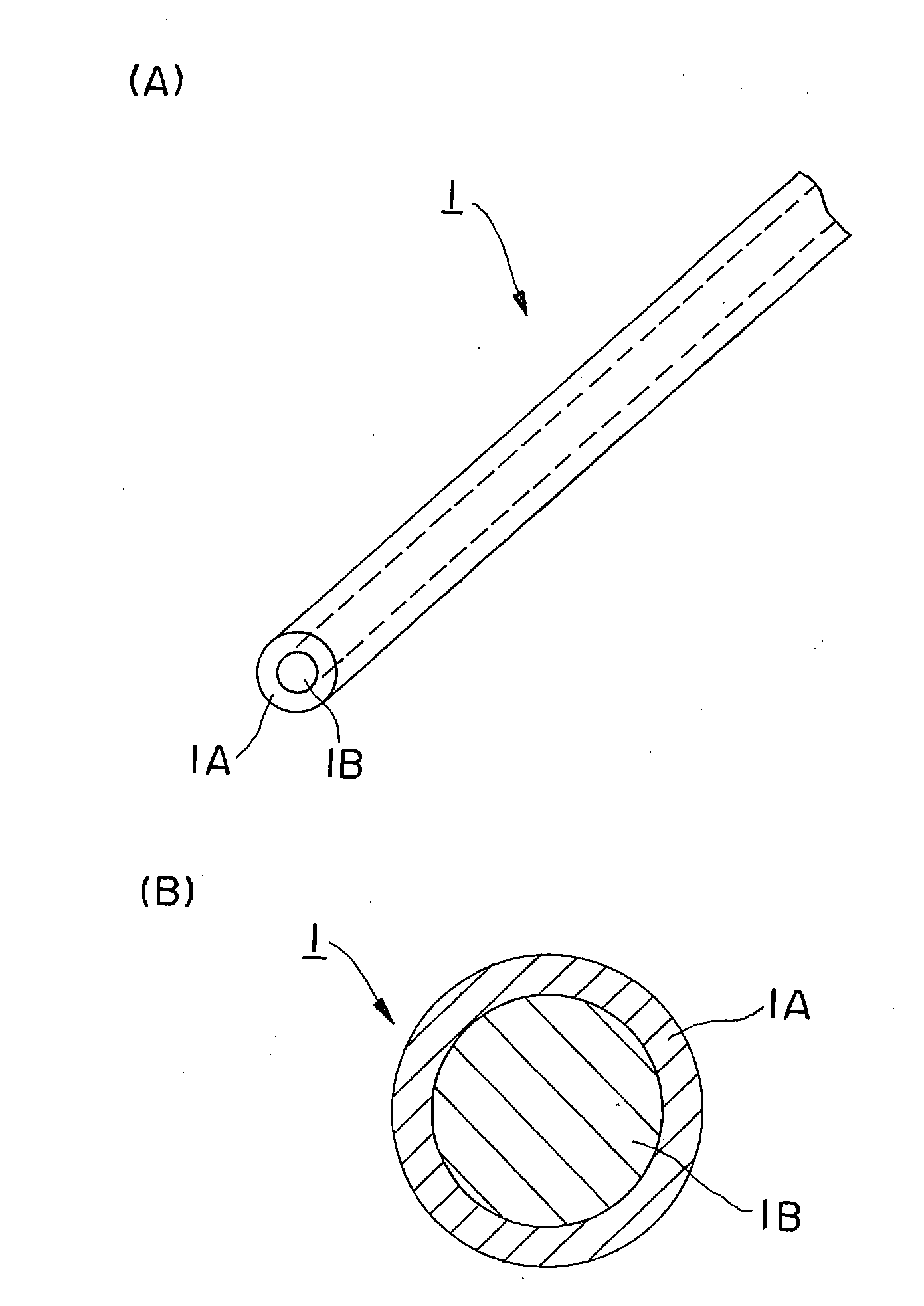

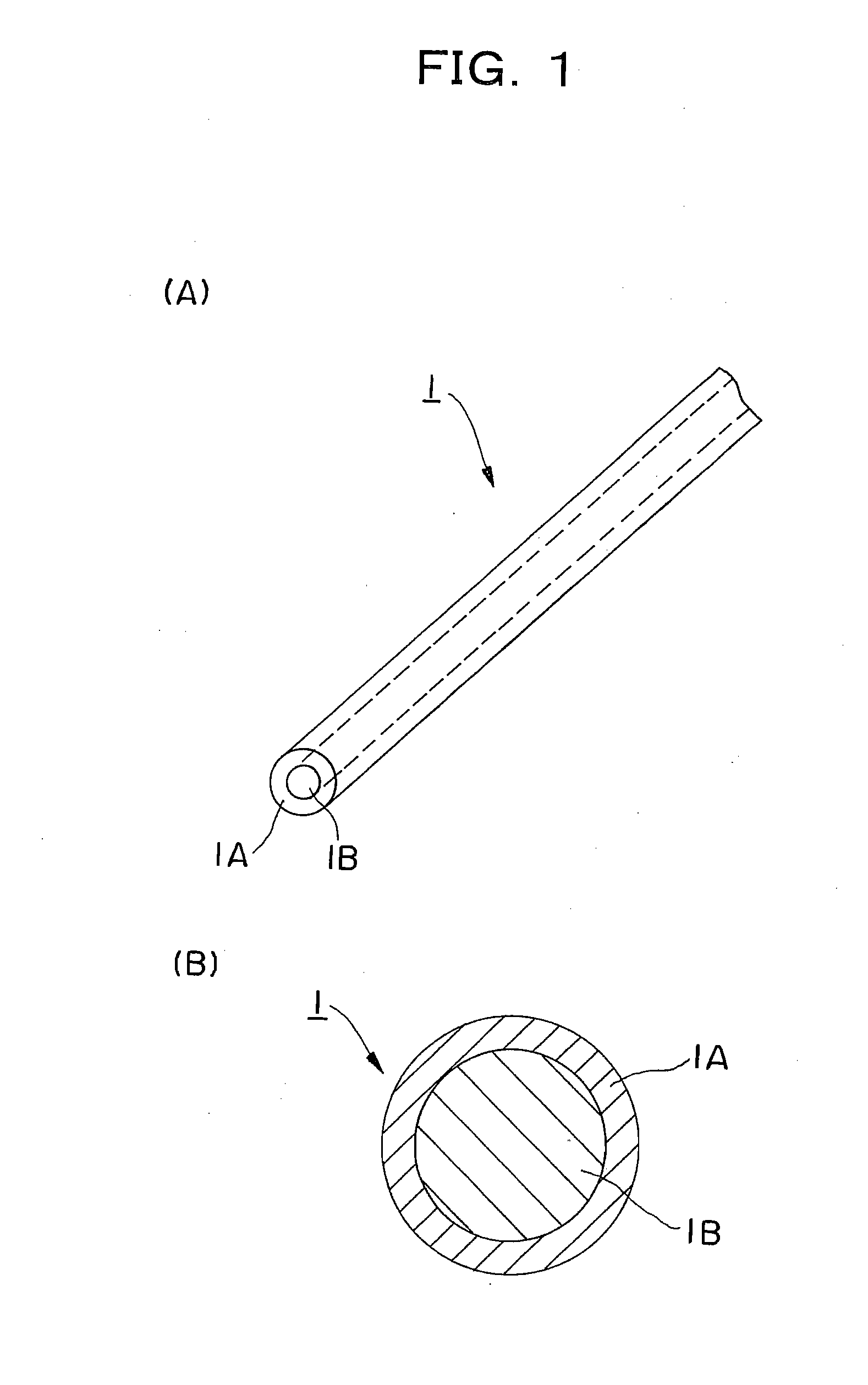

[0102]Using the spinning machine 20 shown in FIG. 3, the artificial hair 10 of Example 1 was manufactured. As a polyamide resin for the core portion 1B, nylon 6T (TOYOBO, LTD.) was used, and as a polyamide resin for the sheath portion 1A, nylon 6 (TOYOBO, LTD.) was used. For the quenching bath 24, hot water of 80° C. was used. By setting the sheath / core volume ratio as 1 / 7, and the outlet temperature at 310° C., the artificial hair 10 was manufactured. The sheath / core weight ratio was 12 / 88 for the artificial hair 10 of Example 1.

[0103]As a coloring agent, resin chips were used which were made by blending a polyamide resin used either for said sheath 1A or for core 1B and a pigment in pre-determined ratio, heating and melting, and cooling after kneading. These resin chips used as a coloring agent were defined as the master batch. As the master batch used in Example, the resin chips containing 3 weight % bl...

example 2

[0110]The artificial hair 10 of the sheath / core structure was manufactured by the same condition as Example 1, except that the sheath / core volume ratio was made 1 / 5 by adjusting respective gear pumps 21B and 22B. The sheath / core weight ratio of the artificial hair 10 of Example 2 was 16.1 / 83.9.

example 3

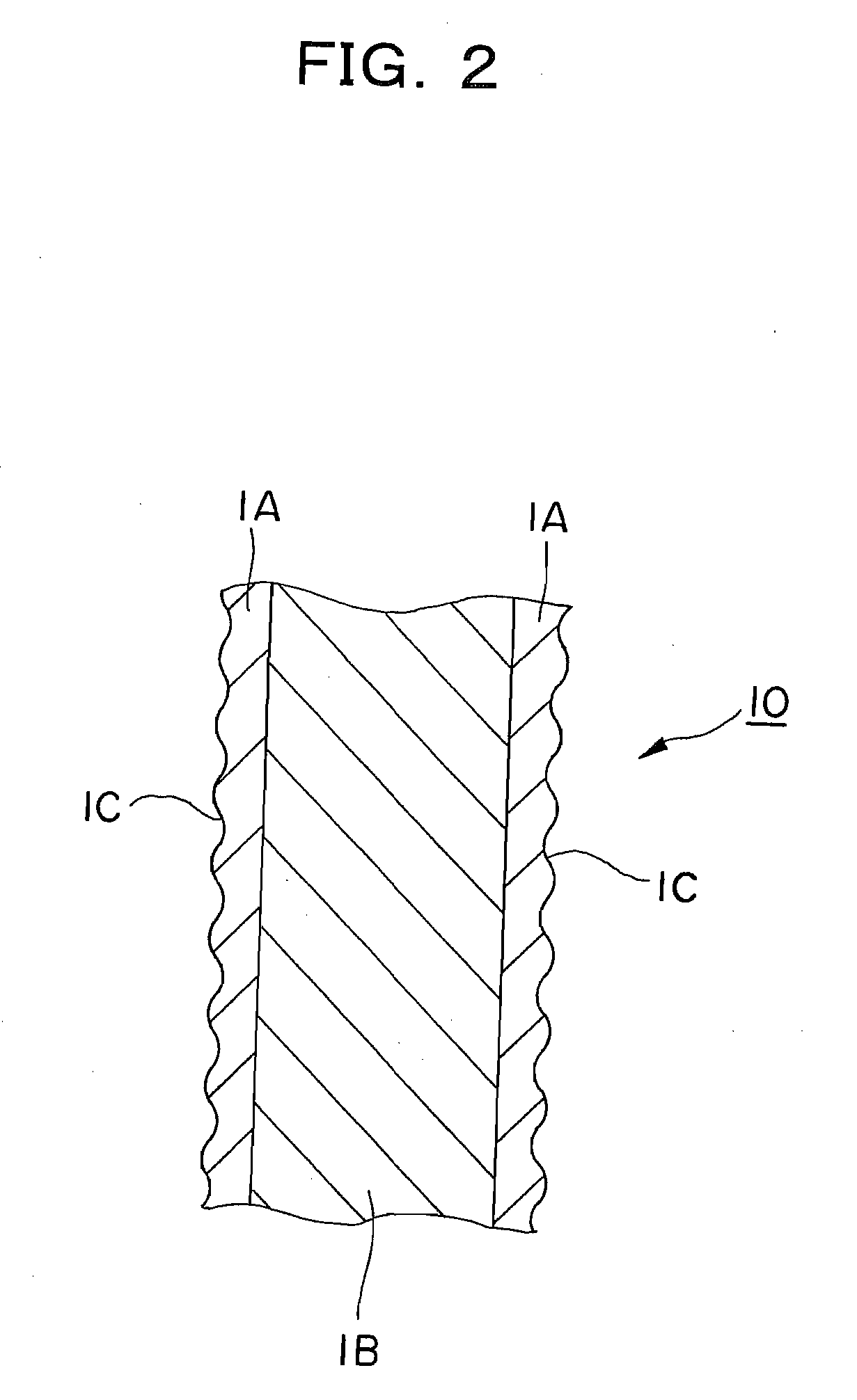

[0111]The artificial hair 10 of the sheath / core structure was manufactured by the same condition as Example 1, except that the sheath / core volume ratio was made 1 / 3 by adjusting respective gear pumps 21B and 22B. The sheath / core weight ratio of the artificial hair 10 of Example 3 was 24.2 / 75.8, and its diameter was 80 μm.

[0112]FIG. 7 is a graph showing the stretching ratio dependency of rigidity for bending of the artificial hair 10 of Example 3. In the figure, an abscissa axis shows a stretching ratio, and an ordinate axis shows rigidity for bending: 10−5 gfcm2 / strand. The measurement condition was temperature 22° C. and humidity 40%. As is obvious from FIG. 7, the rigidities for bending for stretching ratios 3 and 5.5 were 430×10−5 gfcm2 / strand and 720×10−5 gfcm2 / strand, showing that rigidity for bending increased linearly with the increase of stretching ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current | aaaaa | aaaaa |

| Digital information | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com