Semiconductor range-finding element and solid-state imaging device

a technology of solid-state imaging and electromagnetic field, which is applied in the direction of reradiation control devices, instruments, etc., can solve the problems of shooting noise causing the drop in range measurement precision, the inability of range-finding sensors and the inability to effectively reduce the influence of background light. achieve the effect of wide dynamic range, wide range measurement precision, and wide maximum range measurement coverag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

Modification of First Embodiment

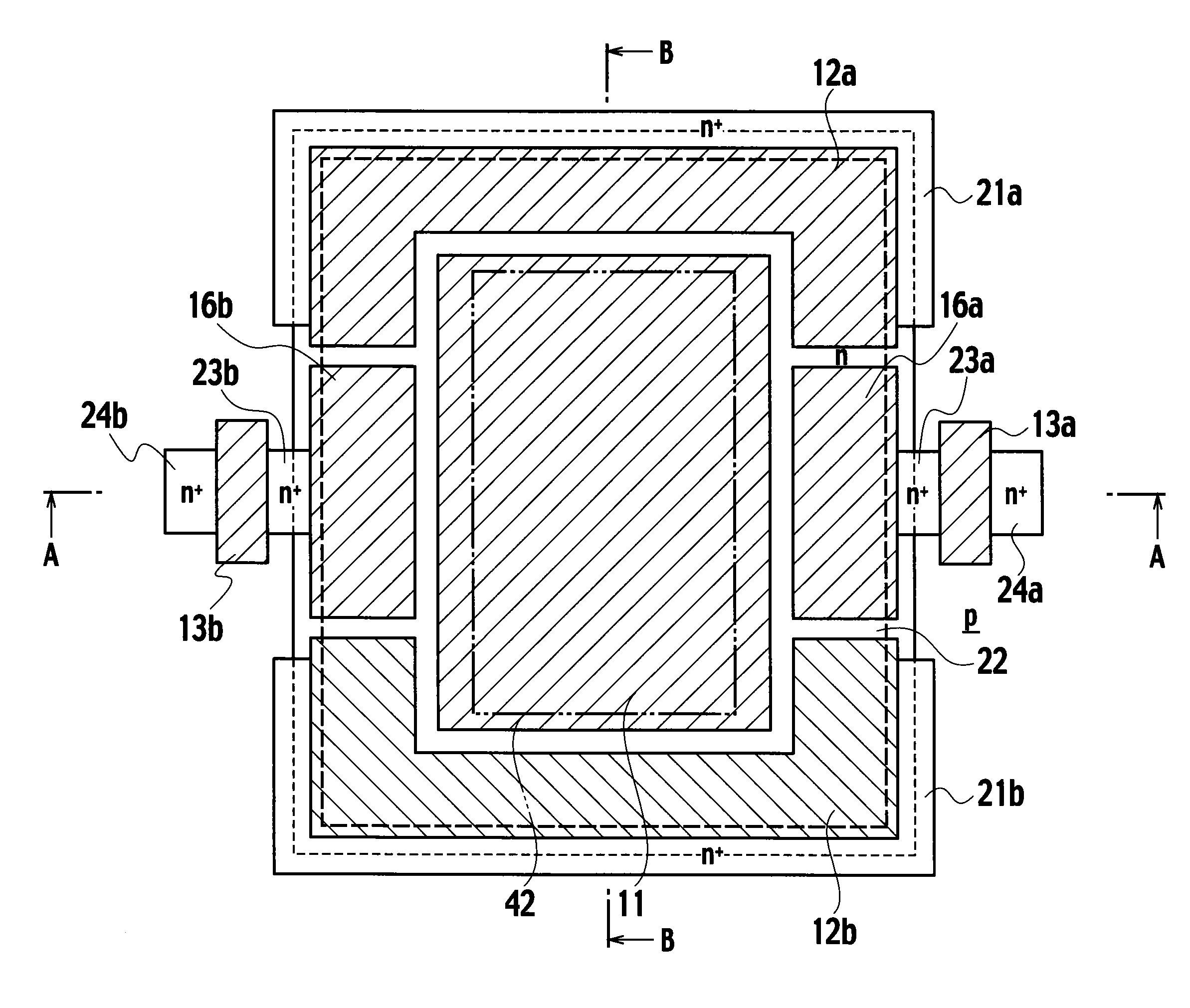

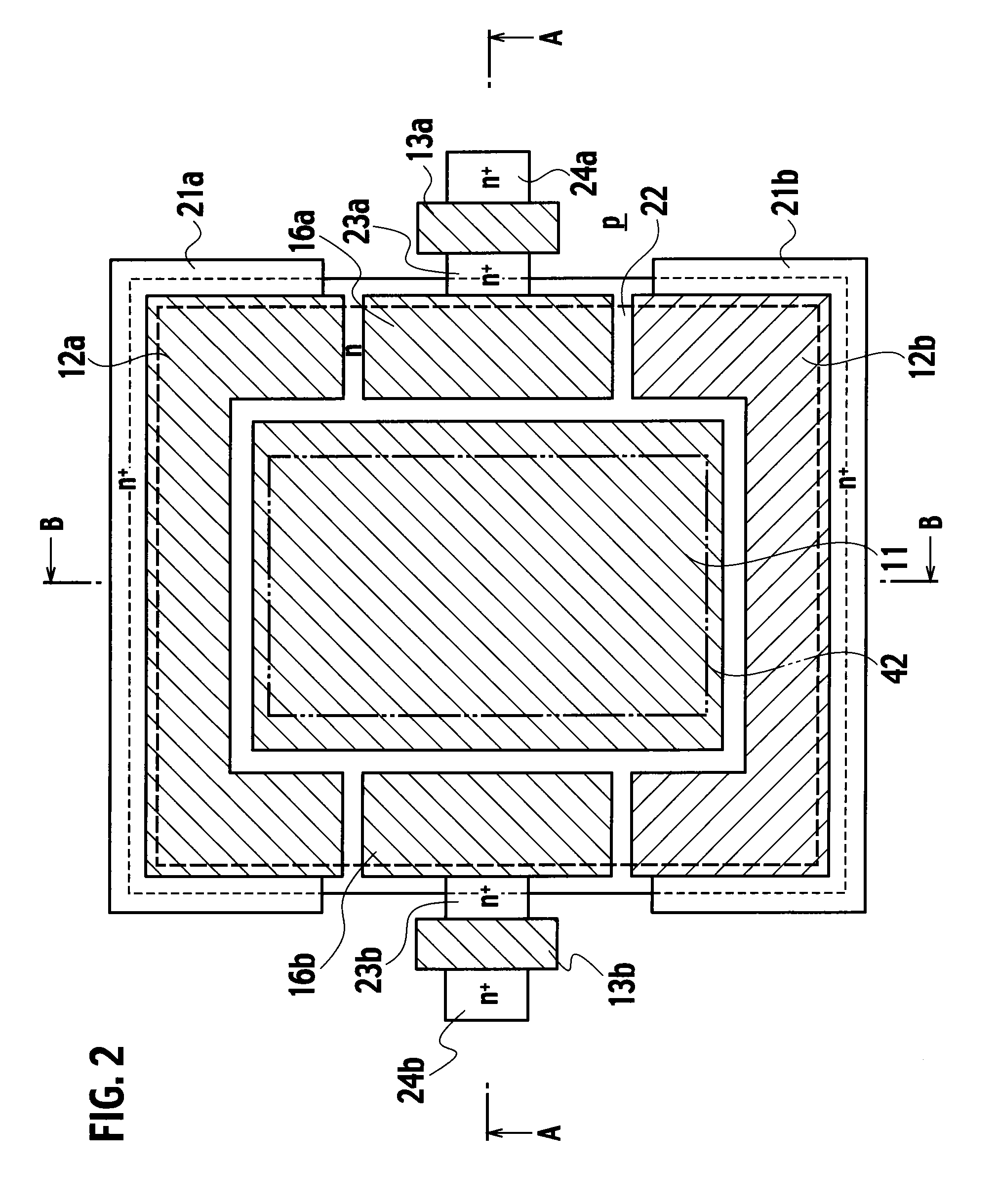

[0069]As shown in FIG. 2, in the semiconductor range-finding element according to the first embodiment, on the planar pattern, the respective central lines (whose illustrations are omitted) of the first transfer gate electrode 16a and the second transfer gate electrode 16b are aligned on the same straight line A-A in the horizontal direction (right and left direction) in FIG. 2, and the respective widths of the first transfer gate electrode 16a and the second transfer gate electrode 16b that are measured in the direction (the upper and lower direction in FIG. 2) orthogonal to the transfer direction of the signal charges are made narrower than the width of the light-receiving gate electrode 11 measured in the orthogonal direction. This structure is advantageous in that, even if the area of the light-receiving region directly under the light-receiving gate electrode 11 is increased, the perfect transfer of the signal charges through the first transfer g...

second embodiment

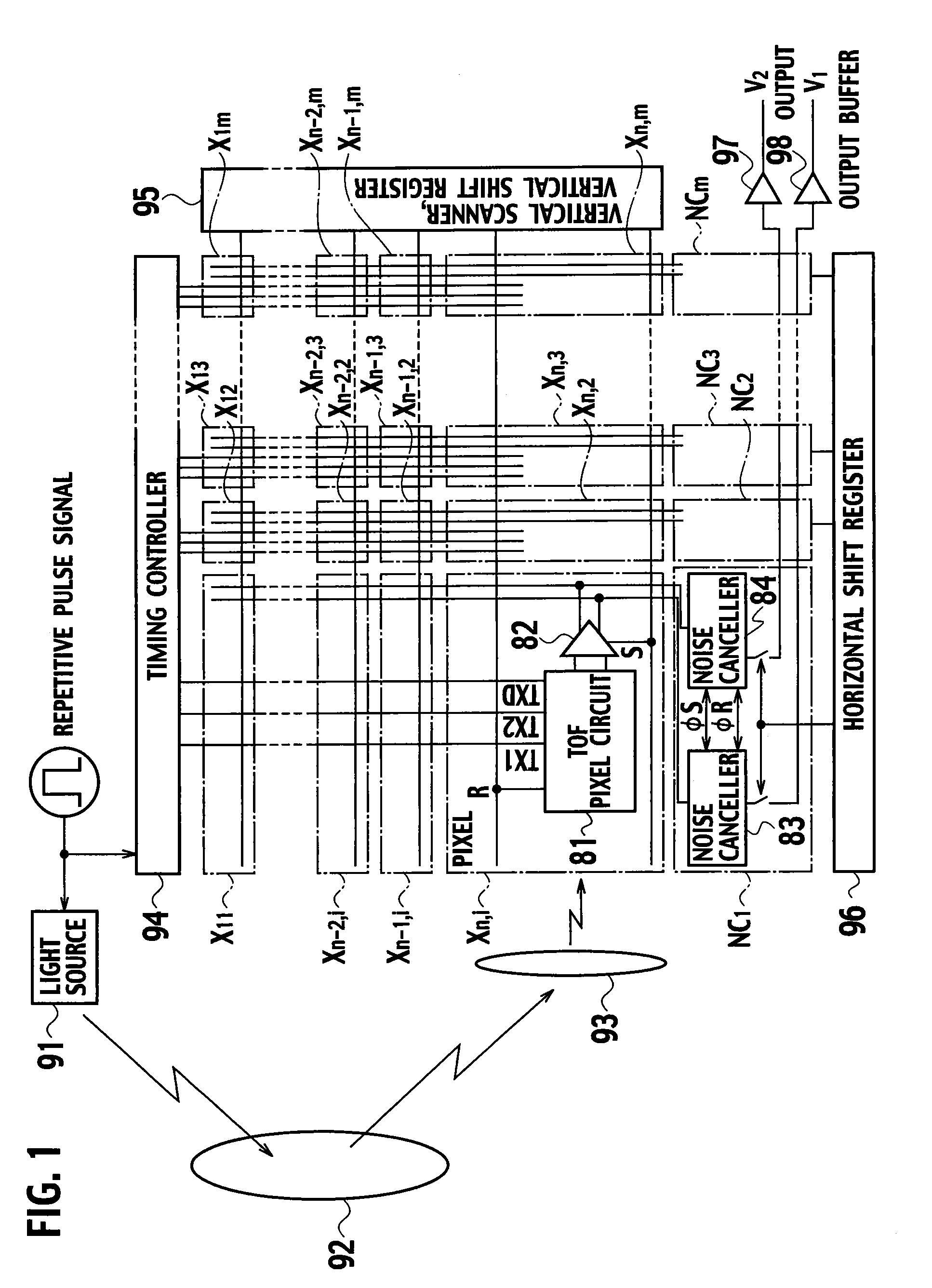

[0072]The entire configuration of a solid-state imaging device (two-dimensional image sensor) according to the second embodiment of the present invention is equivalent to the block diagram shown in FIG. 1. Thus, the overlapping or redundant description is omitted. However, the structure of the semiconductor range-finding element, which has the planar configuration shown in FIG. 12 and serves as the TOF pixel circuit 81 assigned in each of the pixels X11 to X1m, X21 to X2m, - - - , Xn1 to Xnm in the solid-state imaging device according to the second embodiment, differs from the planar configuration of the semiconductor range-finding element according to the first embodiment.

[0073]That is, the semiconductor range-finding element according to the second embodiment of the present invention has the function for reading even the component, which is caused by the background light, out to the external and canceling the background light component. Therefore, as shown in FIG. 12, a first floa...

third embodiment

[0083]The entire configuration of a solid-state imaging device (two-dimensional image sensor) according to the third embodiment of the present invention is equivalent to the block diagram shown in FIG. 1. Thus, the overlapping or redundant description is omitted. However, the structure of the semiconductor range-finding element, which has the cross-sectional structure shown in FIG. 14 and serves as the TOF pixel circuit 81 assigned in each of the pixels X11 to X1m, X21 to X2m, - - - , Xn1 to Xnm in the solid-state imaging device according to the third embodiment, differs from the cross-sectional structure of the semiconductor range-finding element according to the first embodiment, in that the semiconductor range-finding element according to the third embodiment does not contain the surface buried region 22. However, since the planar configuration is similar to the planar configuration of the semiconductor range-finding element according to the first embodiment shown in FIG. 2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com