Double-wall-tube heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

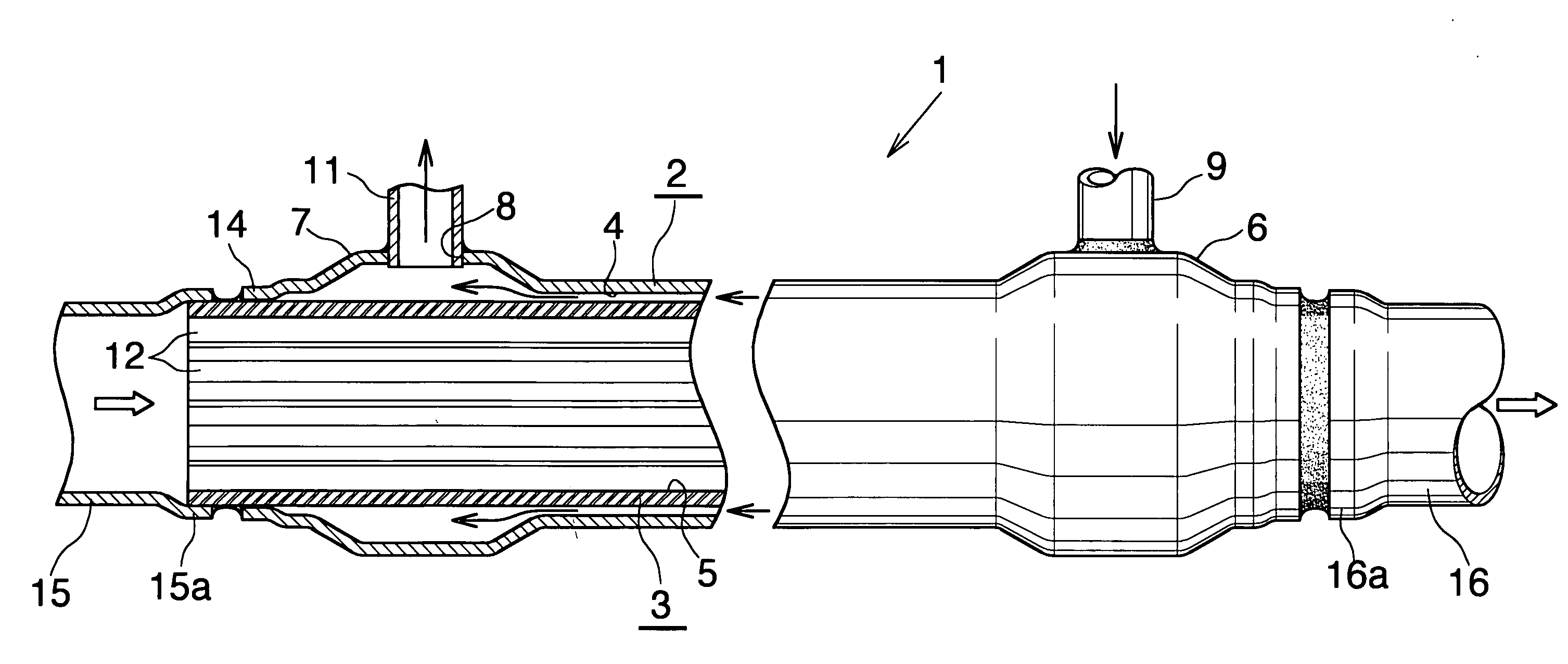

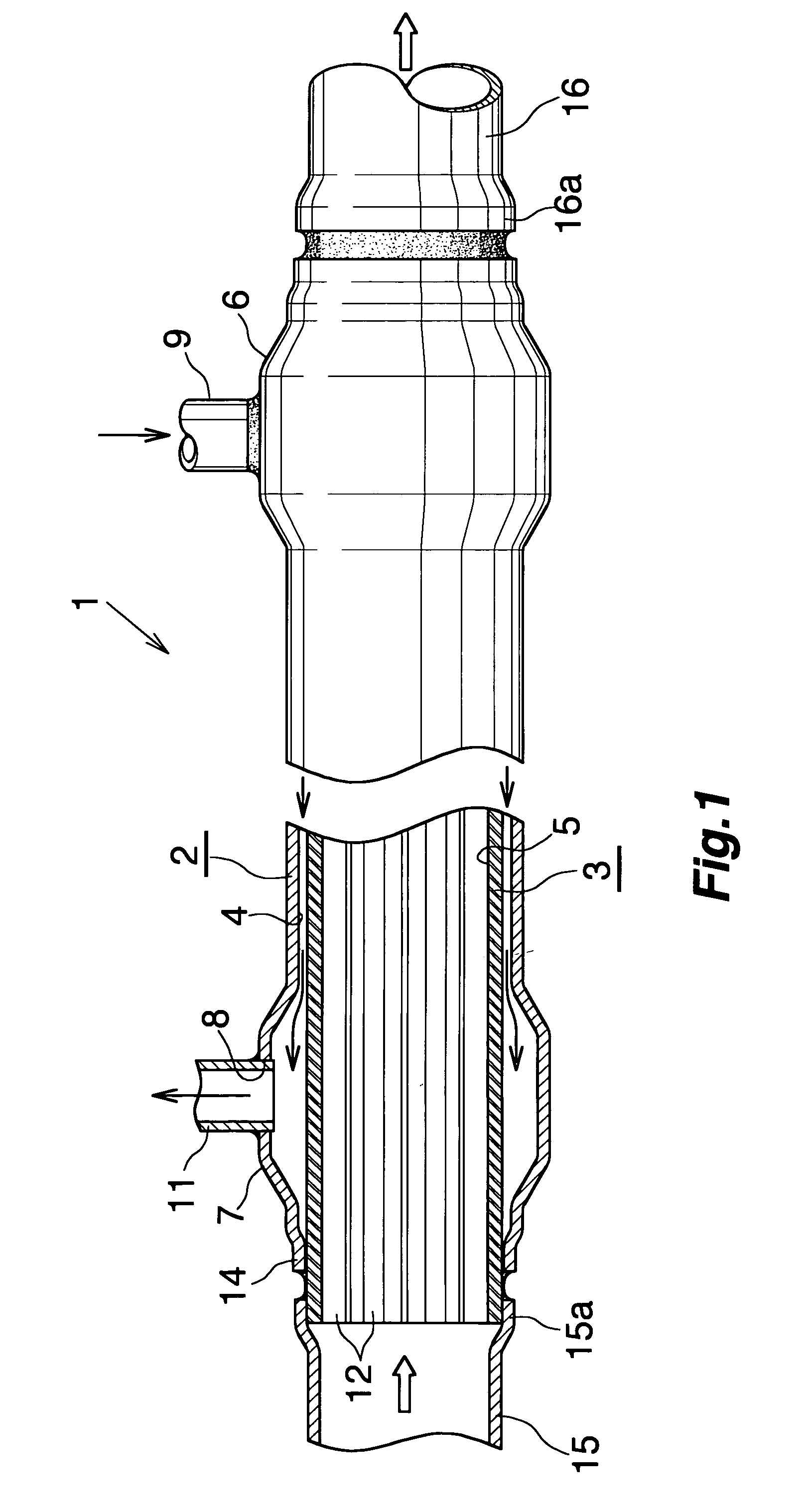

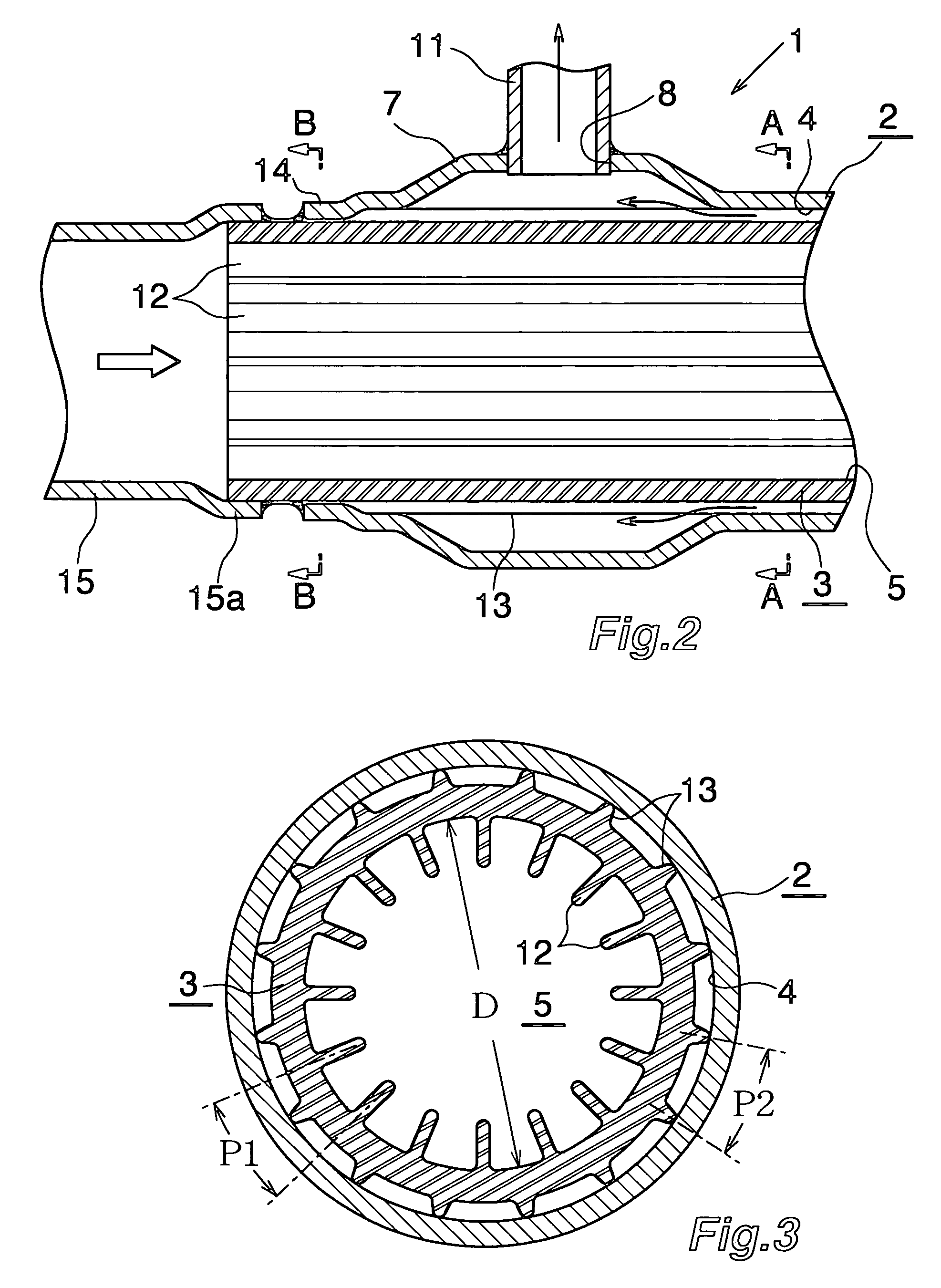

[0056]The present embodiment is shown in FIGS. 1 to 7.

[0057]FIG. 1 shows the configuration of a double-wall-tube heat exchanger according to Embodiment 1 of the present invention. FIGS. 2 to 6 show the configurations of essential portions of the double-wall-tube heat exchanger. FIG. 7 shows a refrigeration system which uses the double-wall-tube heat exchanger of Embodiment 1 as an intermediate heat exchanger.

[0058]In FIGS. 1 to 5, a double-wall-tube heat exchanger 1 includes an outer tube 2 and an inner tube 3. The outer tube 2 is formed of an aluminum extrudate having a circular cross section. The inner tube 3 is formed of an aluminum extrudate having a circular cross section and is inserted concentrically into and spaced apart from the outer tube 2. A clearance between the outer tube 2 and the inner tube 3 serves as a first refrigerant flow path 4. The interior of the inner tube 3 serves as a second refrigerant flow path 5.

[0059]The outer tube 2 has expanded tube portions 6 and 7 ...

embodiment 2

[0072]The present embodiment is shown in FIGS. 13 to 17.

[0073]FIGS. 13 to 17 show the configurations of essential portions of a double-wall-tube heat exchanger according to Embodiment 2 of the present invention.

[0074]In the case of the double-wall-tube heat exchanger 31 of Embodiment 2, the outer tube 2 has a plurality of elongated projections 32 formed integrally with the inner circumferential surface of the outer tube 2. The elongated projections 32 project radially inward, extend in the longitudinal direction, and are arranged at equal circumferential intervals. Also, the outer tube 2 does not have expanded tube portions at opposite end portions thereof.

[0075]The inner tube 3 has diameter-reduced tube portions 33 located slightly longitudinally inward of the opposite ends thereof. A refrigerant inlet (not shown) is formed in the wall of the outer tube 2 at a position corresponding to one diameter-reduced tube portion (not shown). The refrigerant outlet 8 is formed in the wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com