Hazardous-Environmental Diving Systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

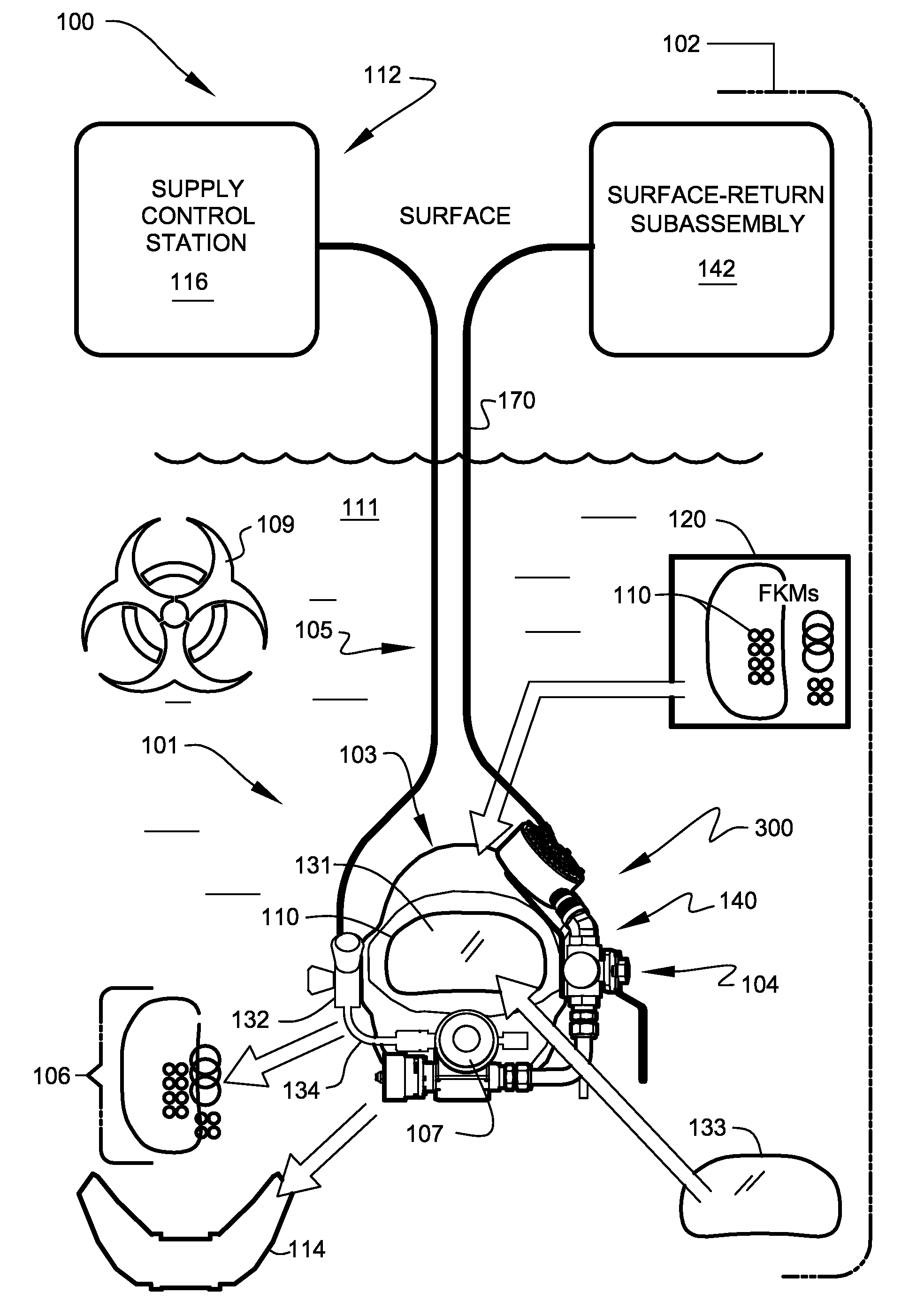

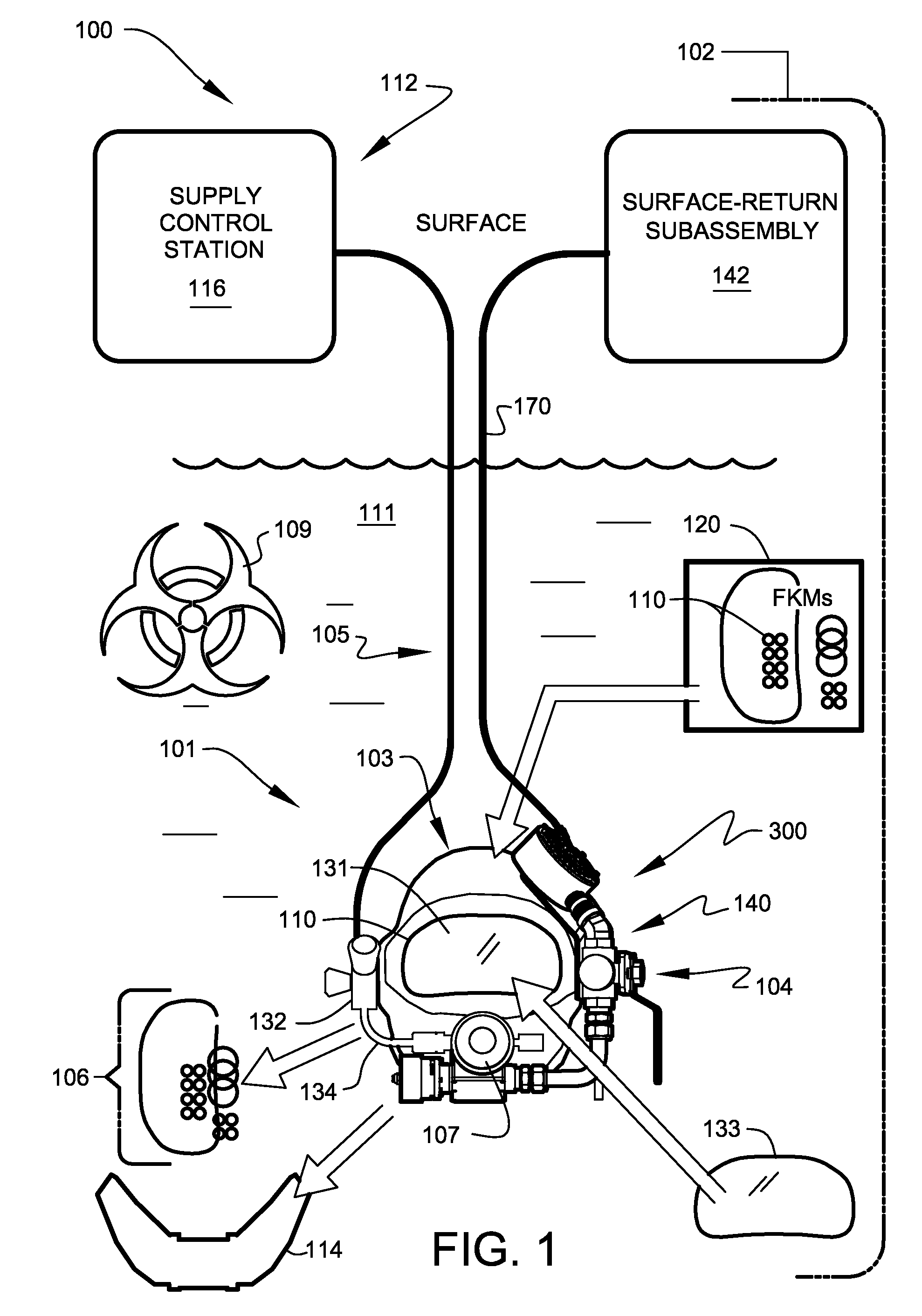

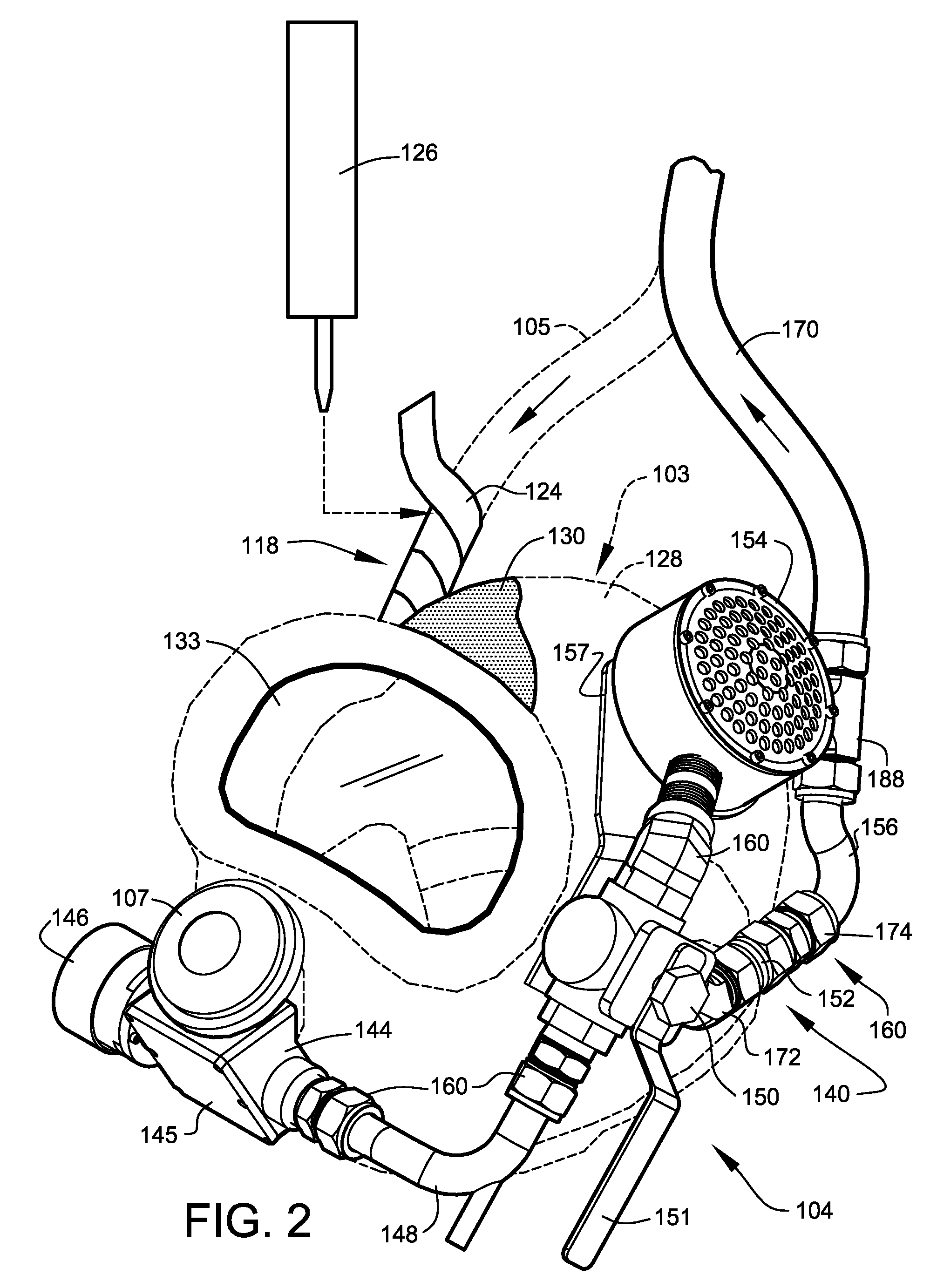

[0034]FIG. 1 shows a schematic diagram, generally illustrating preferred arrangements of Hazardous Material-hardened Regulated Surface Exhaust Diving System (HMRSEDS) 300, according to a preferred embodiment of the present invention. Preferred embodiments of hazardous-environmental diving system 100, preferably including HMRSEDS 300, are preferably generated by applying one or more specific modifications to an existing underwater dive system 101, preferably using a component-based kit system identified herein as Hazardous Environment Modification Assembly (HEMA) 102. HEMA 102 is preferably adapted to implement one or more risk-mitigating modifications to the diver-worn equipment of existing underwater dive system 101. In HMRSEDS 300, HEMA 102 is preferably used to convert a commercially available dive helmet 103 into a fully encapsulated protection system to isolate the diver from hazardous diving environment 111 containing hazardous materials 109.

[0035]The following descriptions ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com