Temperature sensor assembly

a temperature sensor and assembly technology, applied in the field of air temperature sensors, can solve the problems of not preventing the removal and assembly, and achieve the effects of preventing inadvertent displacement, and reducing the risk of damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

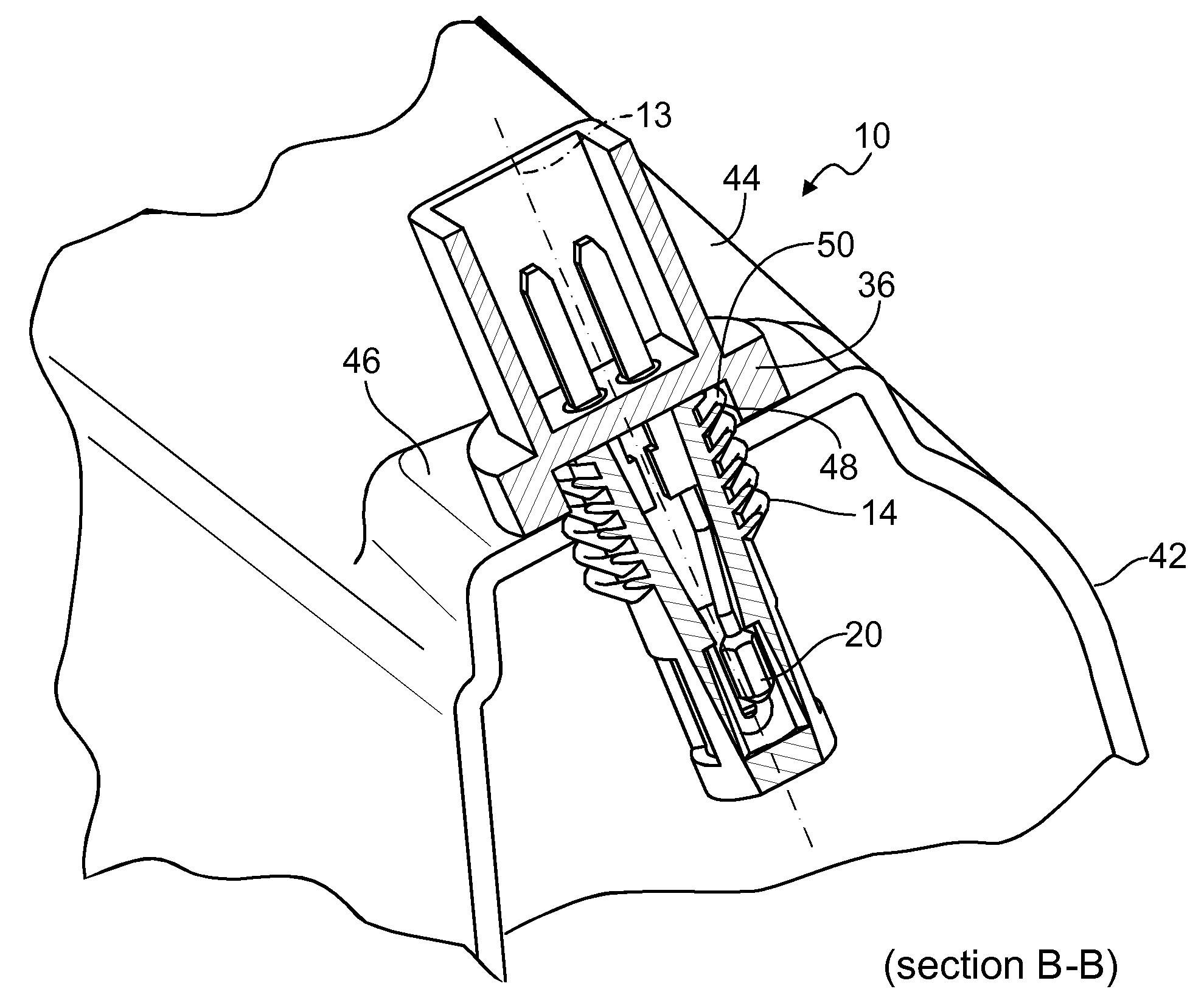

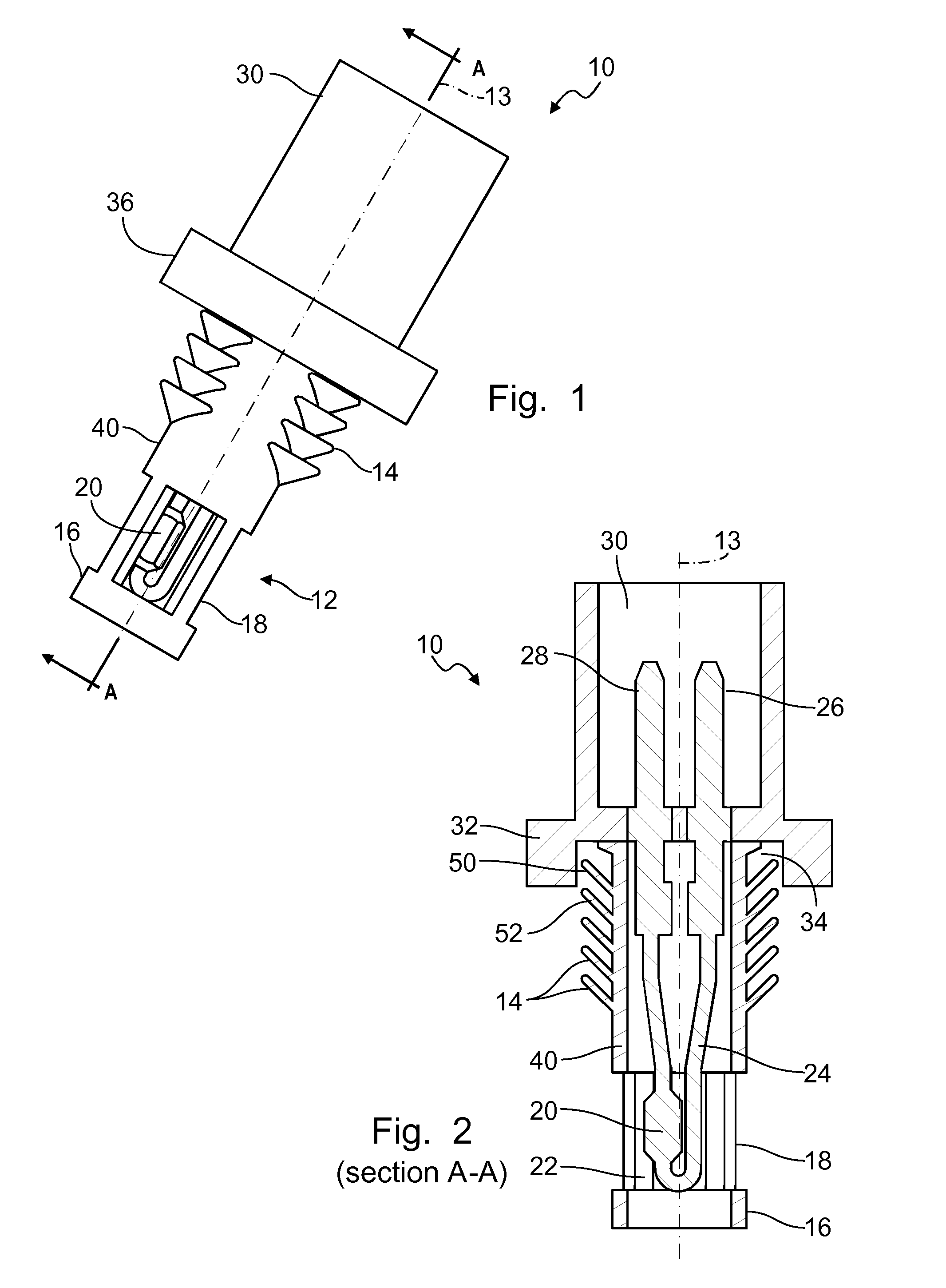

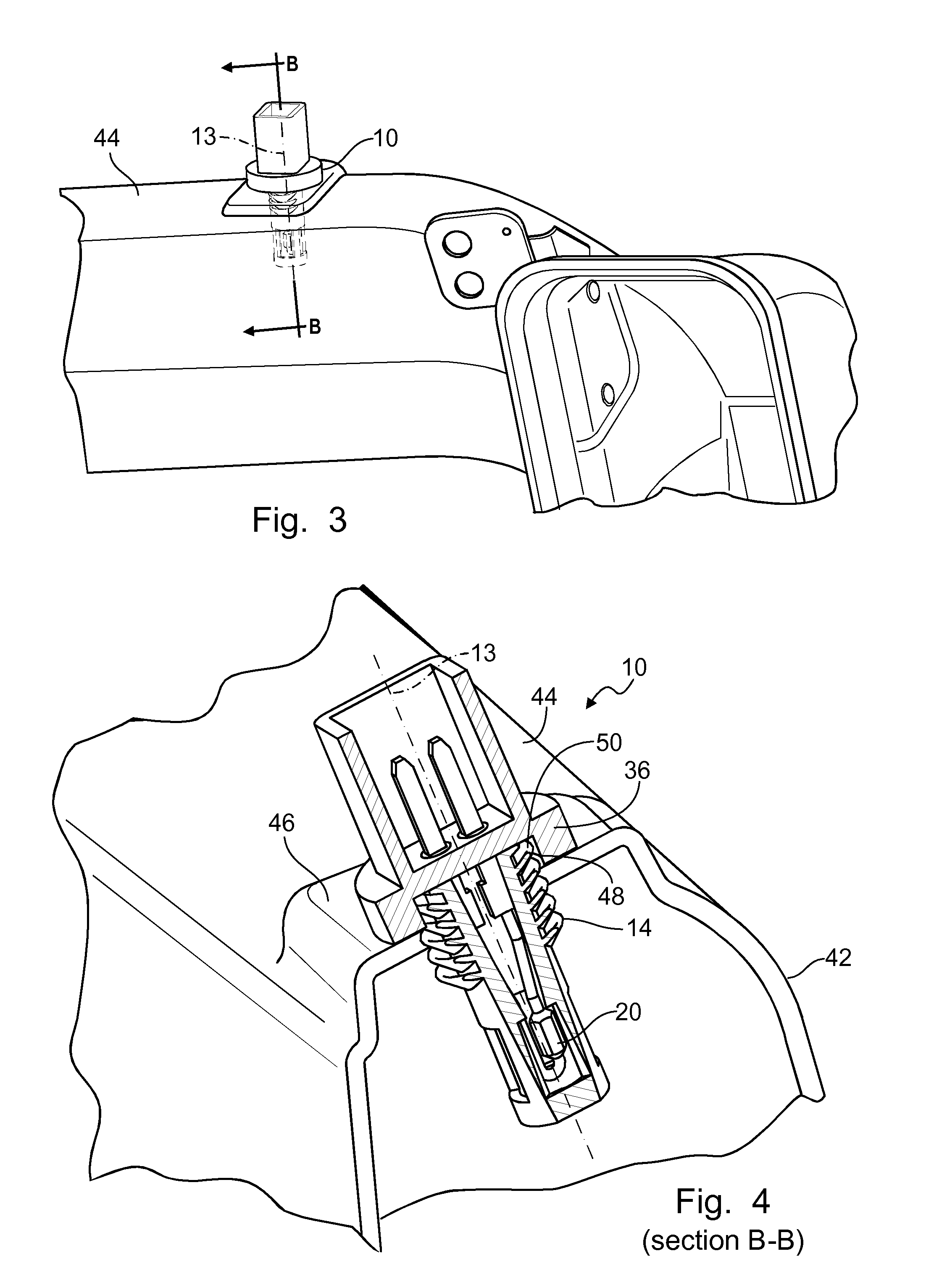

[0013]FIGS. 1 and 2 illustrate an electronic duct air temperature sensor assembly 10 that includes a body 12 having a central axis 13 and formed with a series of ribs 14 spaced along the body, a cylindrical base 16 and a cage 18 containing an air temperature sensor 20. The cage 18 includes open passages 22 that allow air in the duct to flow through the assembly 10 and across the sensor 20.

[0014]Electric conducting leads 24 extend from sensor 20 along the body 12 to terminals 26, 28, which are enclosed in a receptacle portion 30 of the body 12, into which receptacle is inserted a plug secured to a wiring harness (not shown) for electrically engaging the terminals. The body 12 includes a cylindrical shoulder 32, which is formed with an annular recess 34.

[0015]FIG. 2 shows that the ribs 14 extend radially outward and upward toward the shoulder 32. The ribs 14 are relatively thin, flexible, elastically displaceable and resilient, i.e., they tend to return to the position shown in FIG. 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastically resilient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com