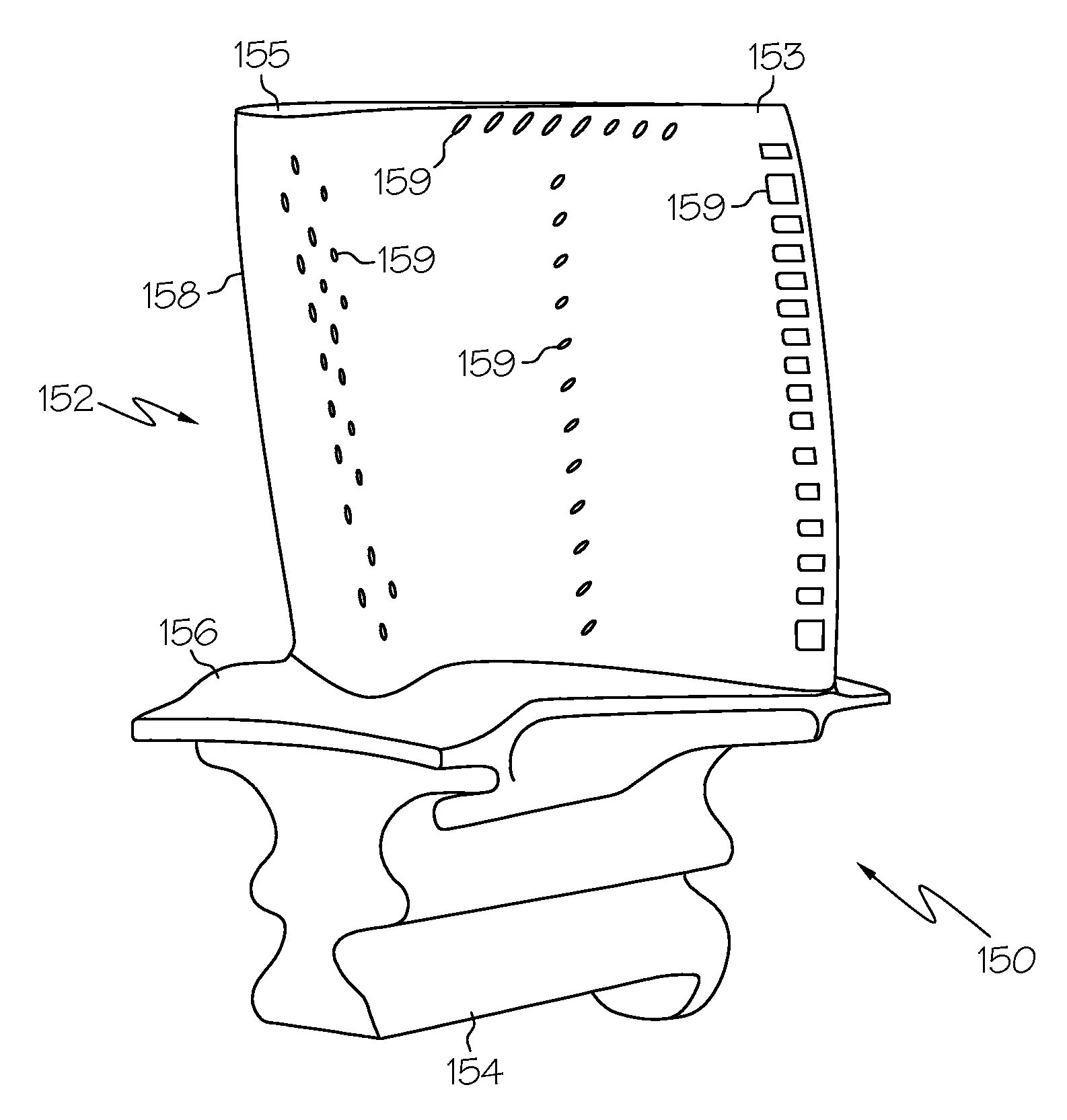

Superalloy compositions with improved oxidation performance and gas turbine components made therefrom

a technology of superalloy and oxidation performance, which is applied in the field of superalloy compositions with improved oxidation performance and gas turbine engine components made therefrom, which can solve the problems of exposed superalloy substrate oxidation, hpt blade oxidation, chemical degradation,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

In Weight Percent

[0041]

Co 9.8-10.2Cr5.2-5.4Mo1.6-1.8W4.8-5.2Re2.8-3.2Ta8.0-9.0Al5.0-5.4Ti0.9-1.1Hf0.08-0.12S≦0.0002Zr≦0.007 OthersLa: 0.001-0.013NiBalance

example 2

In Weight Percent

[0042]

Co 9.8-10.2Cr5.2-5.4Mo1.6-1.8W4.8-5.2Re2.8-3.2Ta8.0-9.0Al5.0-5.4Ti0.9-1.1Hf0.08-0.12S≦0.0002Zr≦0.007 OthersY: 0.001-0.013NiBalance

example 3

In Weight Percent

[0043]

Co 9.8-10.2Cr5.2-5.4Mo1.6-1.8W4.8-5.2Re2.8-3.2Ta8.0-9.0Al5.0-5.4Ti0.9-1.1Hf0.08-0.12S≦0.0002Zr≦0.007 OthersLa and Y (combined weight percent): 0.001-0.013;C: 0.03-0.06;B: 0.004-0.006NiBalance

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com