Reflector element for a solar heat reflector and the method for producing the same

a solar heat reflector and reflector element technology, applied in the field of reflector elements, can solve the problems of sun energy reflection loss, optical deficiencies, environmental concerns, etc., and achieve the effect of preventing water salt pollution deposits on glass surfaces and preventing glass from stress breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

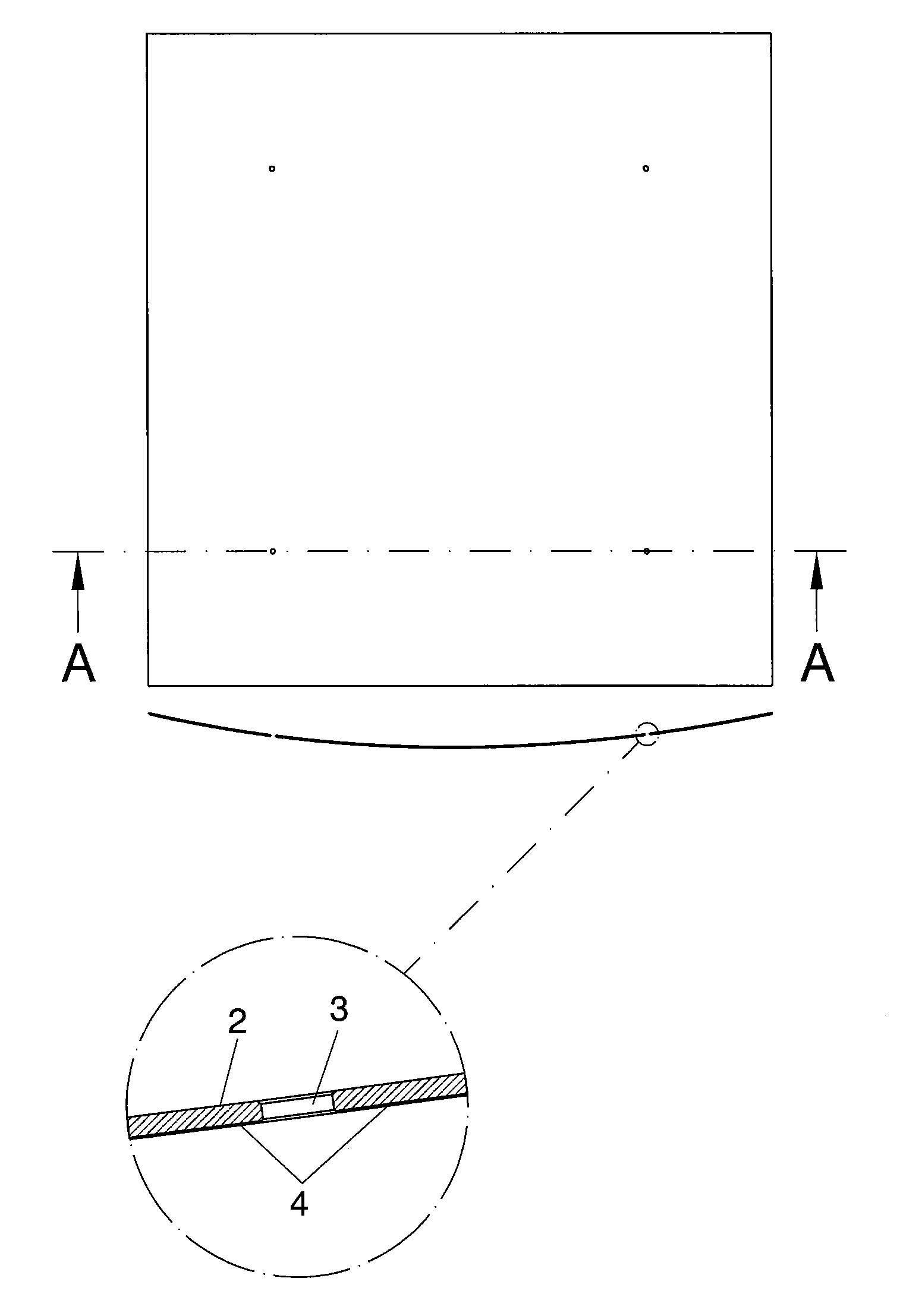

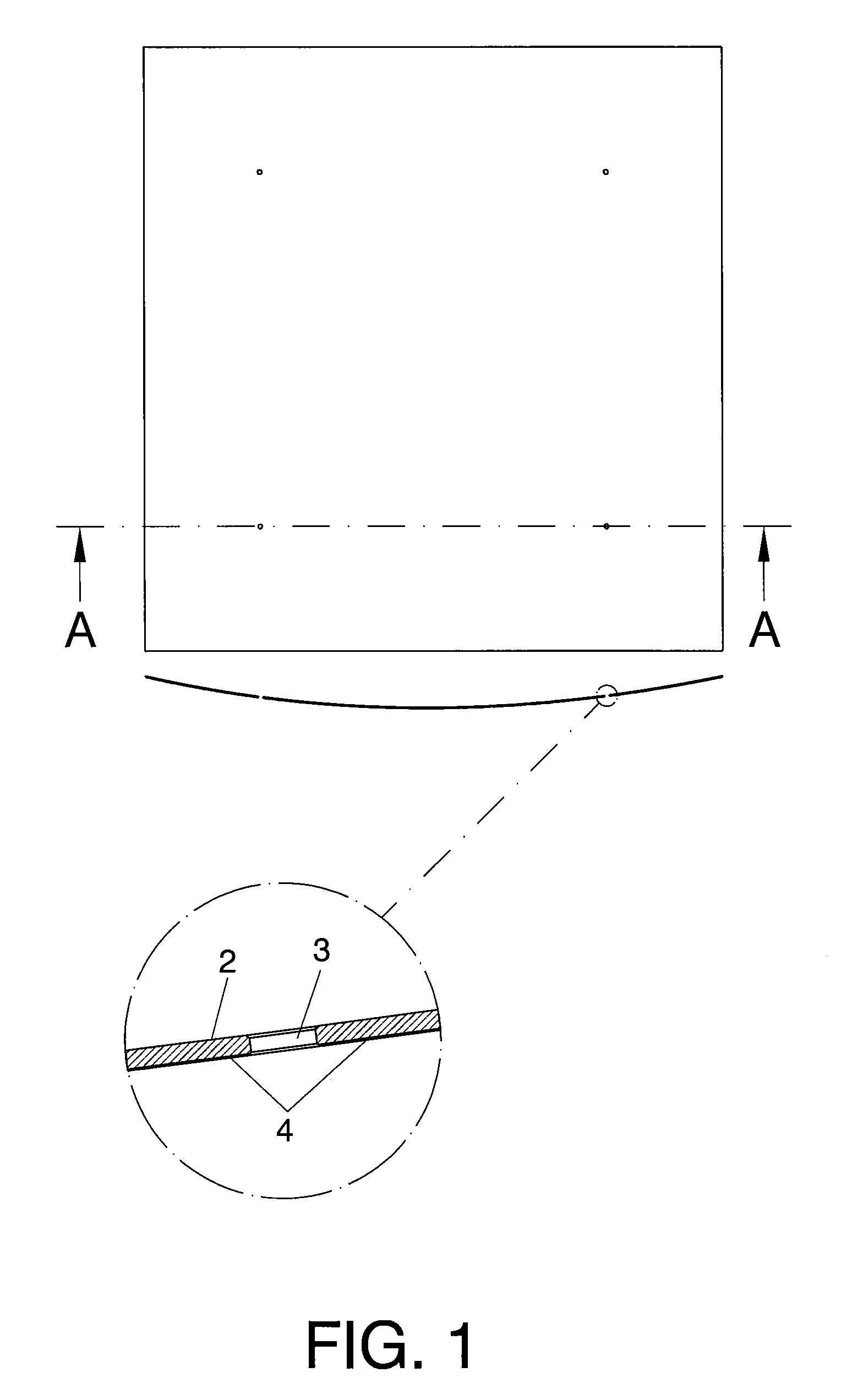

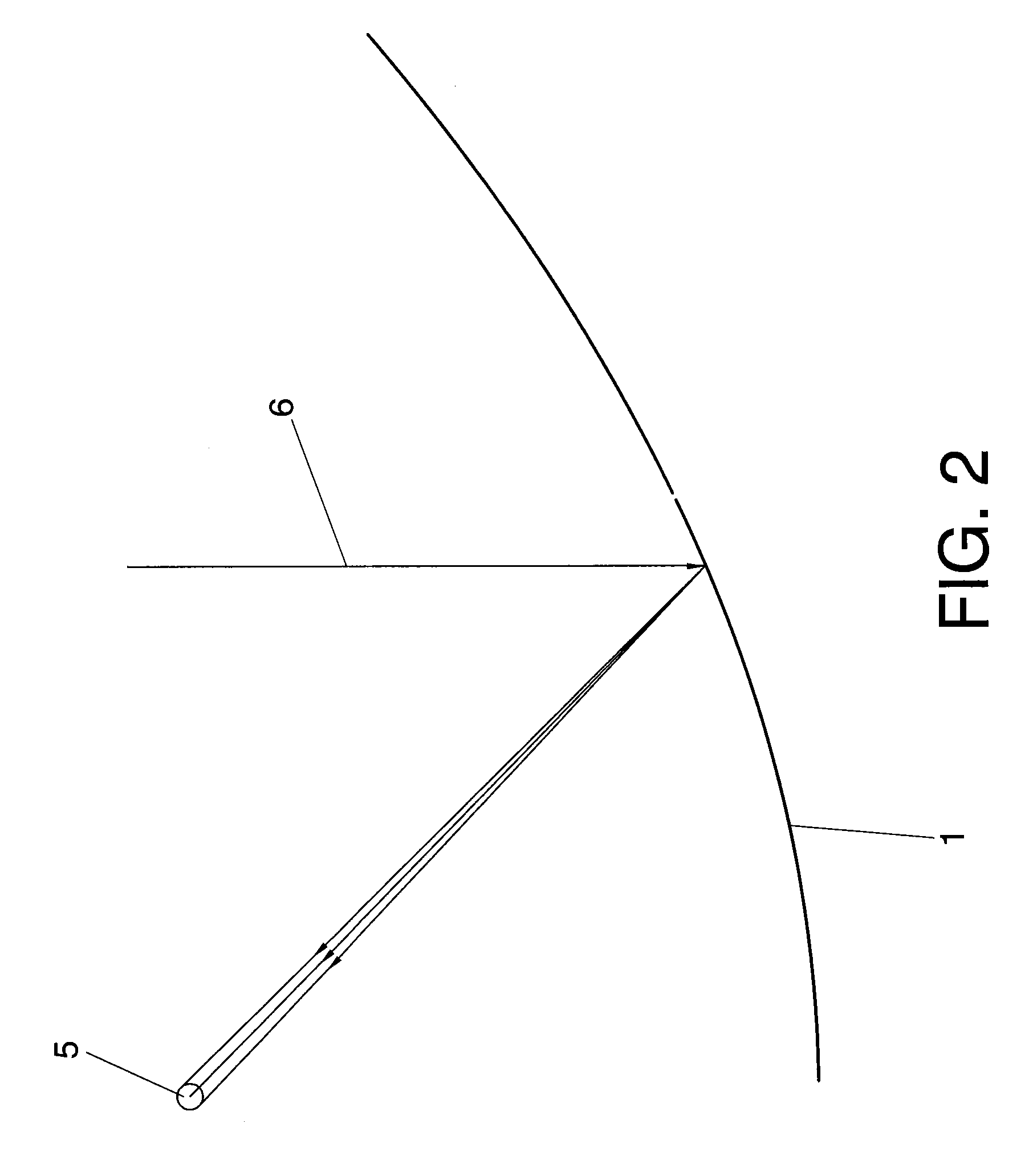

[0055]In FIG. 1 a reflector element (1) for a solar collector according to a preferred embodiment of the invention is shown in both, top and side—section AA—views. Said reflector element comprises a not mechanically flexed monolithic glass pane (2) of heat treated glass which due to its enhanced resistance properties becomes self-supported without requiring the presence of any kind of frame member or device to maintain its shape at the normal utilization temperatures. The principle of reflection of an incident solar ray (6) in a reflector element (1) and the corresponding absorbing tube (5) is shown in FIG. 2.

[0056]In an embodiment the thickness of the glass pane is equal or less than 5 mm.

[0057]FIG. 3 shows the reflector element (1) of the invention and a detail of a conventional mounting means (7) for fixing the reflector element (1) to a solar heat reflector's structure. These conventional mounting means (7), which do not require bores in the reflector, comprises supporting pads ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com