Rotor sail and ship with a rotor sail

a technology of rotor sails and sails, applied in the field of rotor sails, can solve the problems of environmental pollution caused by the drive, and achieve the effect of reducing the risk of damage to the environmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

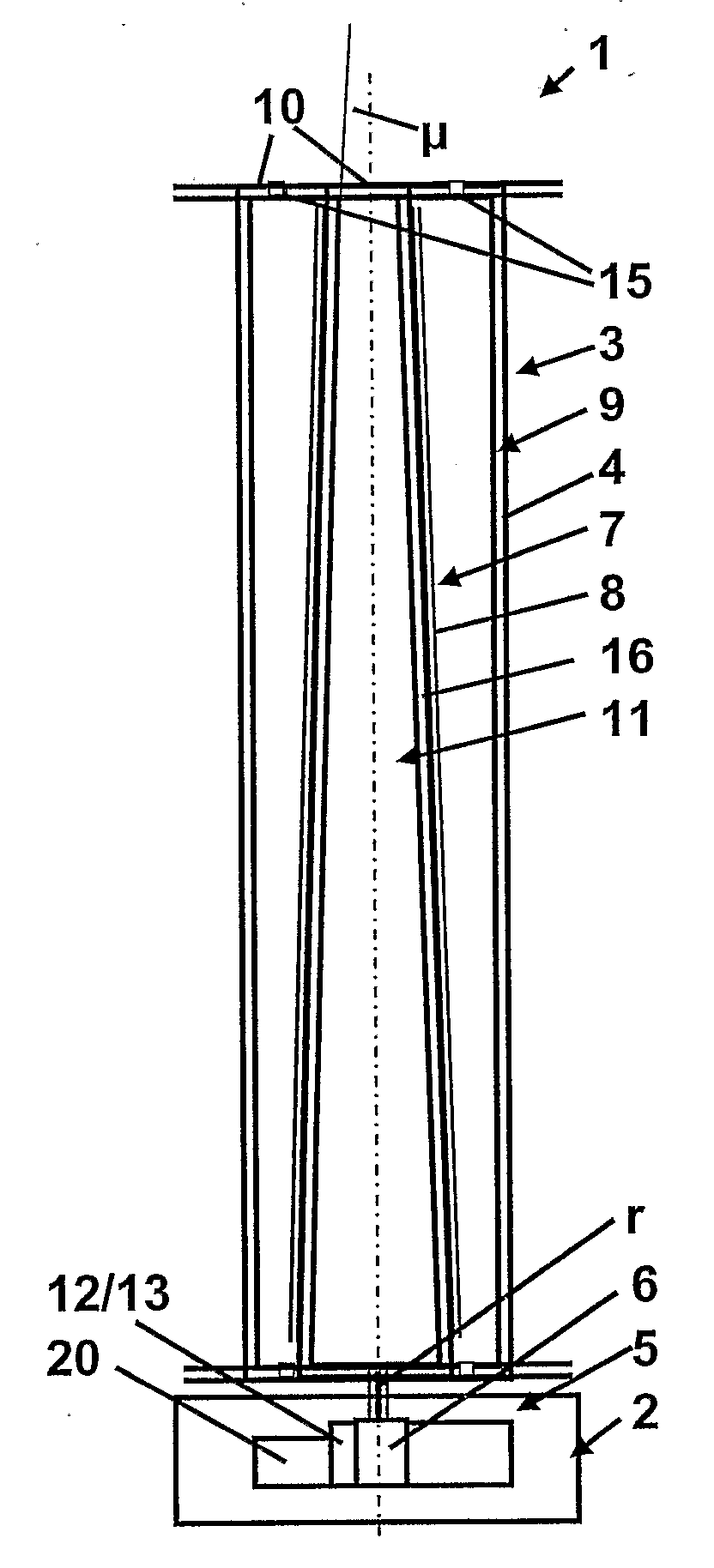

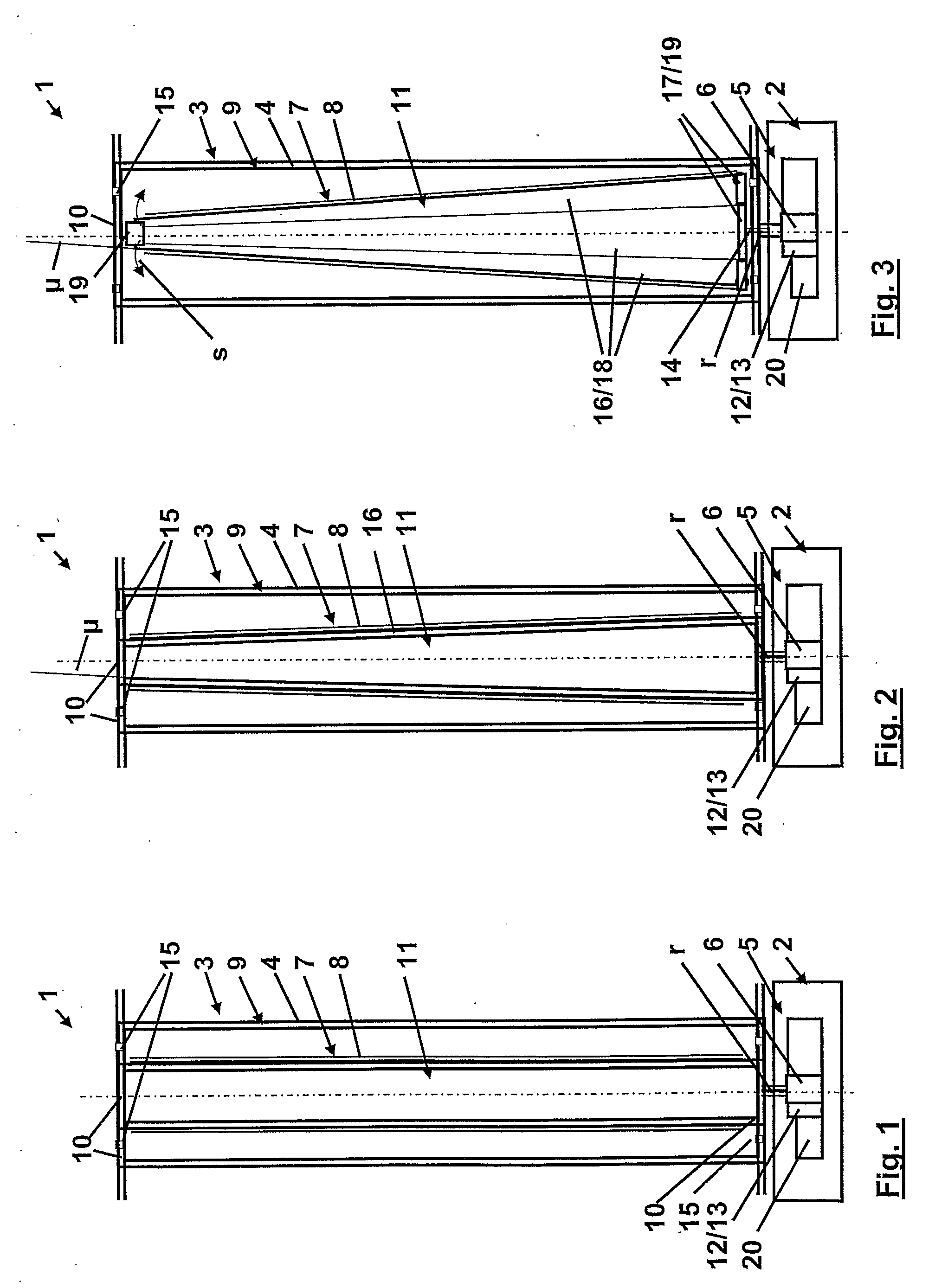

[0029]FIGS. 1 to 3 each show, in the form of a highly schematic and simplified diagram, a rotor sail 1 in three different embodiments. Rotor sail 1 has a base 2, a rotary cylinder 3, which is mounted on base 2 in a manner permitting rotation about its longitudinal axis designed as the rotor axis r, and whose enclosing outer surface 4 serves as a wind-exposed surface in operation, and a drive 5 having an electric motor 6 for rotating rotary cylinder 3. Drive 5 and motor 6 are located in base 2, where rotor axis r extends into drive 5.

[0030]According to embodiments of the invention, a photovoltaic system 7 with solar cells 8 is provided to generate electric energy for drive 5. Solar cells 8 are arranged in rotary cylinder 3 in such a way that their photoelectrically active layers face toward enclosing outer surface 4. Provision is furthermore made for rotary cylinder 3 to be of transparent design in its sleeve 9 and in its end face 10 pointing away from base 2. Moreover, end faces 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com