High Strength Thick-Gauge Electric-Resistance Welded Steel Pipe Excellent in Hardenability, Hot Workability and Fatigue Strength and Method of Production of the Same

a technology of electric resistance and welded steel pipe, which is applied in the direction of furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems that cannot be said to be sufficient in terms of fatigue characteristics either, and achieve the effects of excellent hardenability, sufficient hardening effect and sufficient hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

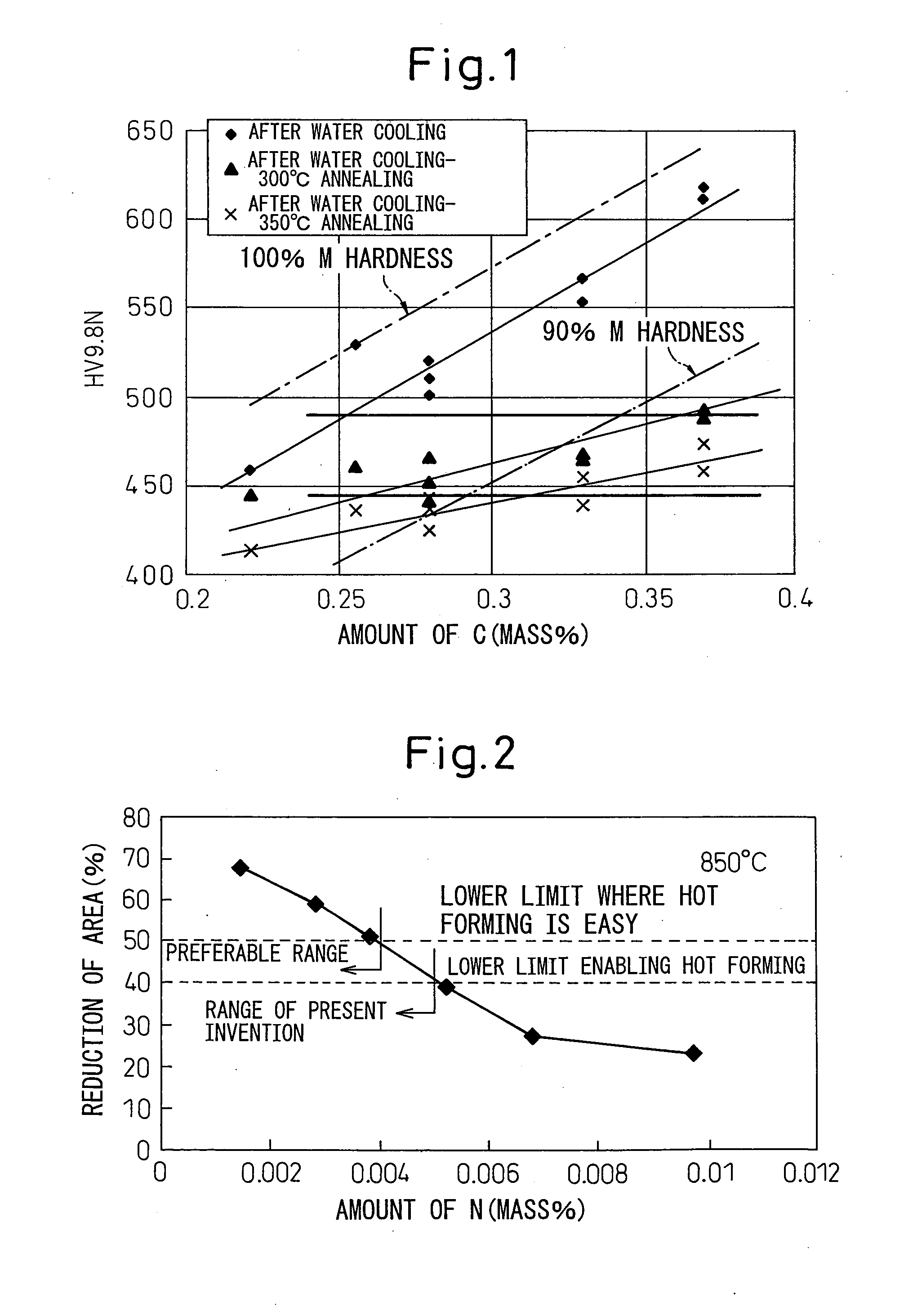

[0079]Various steels having the compositions shown in Table 2 were melted and cast into slabs. Each slab was heated to 1150° C. and hot rolled at a rolling finish temperature of 890° C. and a coiling temperature of 630° C. to obtain steel sheet having a sheet thickness of 6 mm. This hot rolled steel sheet was slit to predetermined widths and welded by high frequency electric-resistance welding to obtain electric-resistance welded steel pipe (master pipe) with an outside diameter of 90 mm. Next, high frequency induction heating was used to heat this steel pipe to 980° C., then this was stretch reducing rolled to obtain thick-gauge electric-resistance welded steel pipe having a thickness of 7 mm and an outside diameter of 35 mm.

[0080]Further, the electric-resistance welded steel pipe produced by the Steel No. 1 of Table 2 was changed in cross-section reduction rate in the stretch reducing rolling to produce thick-gauge electric-resistance welded steel pipe having a thickness of 5 to 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical cooling rate | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com