Structural building component having a decorative overmolding, apparatus for fabricating such an article and its method of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

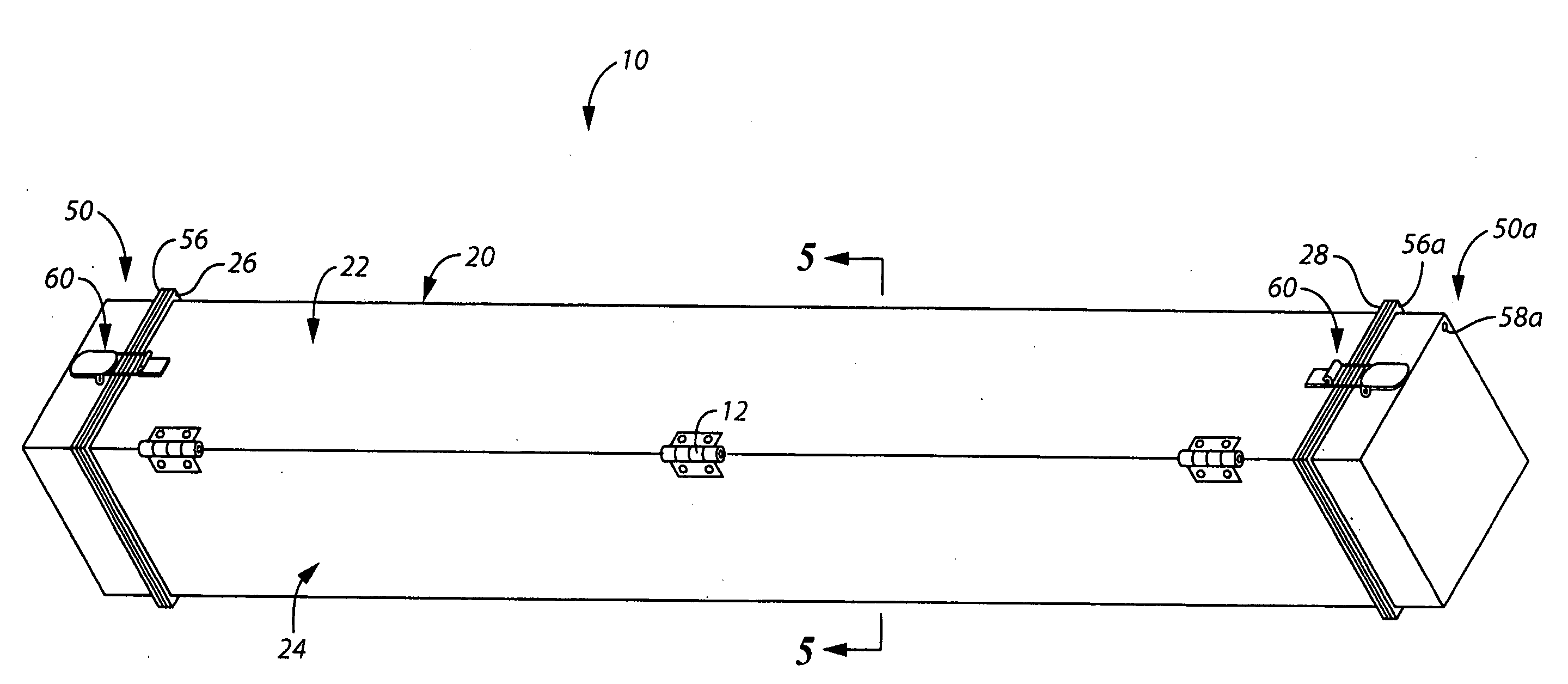

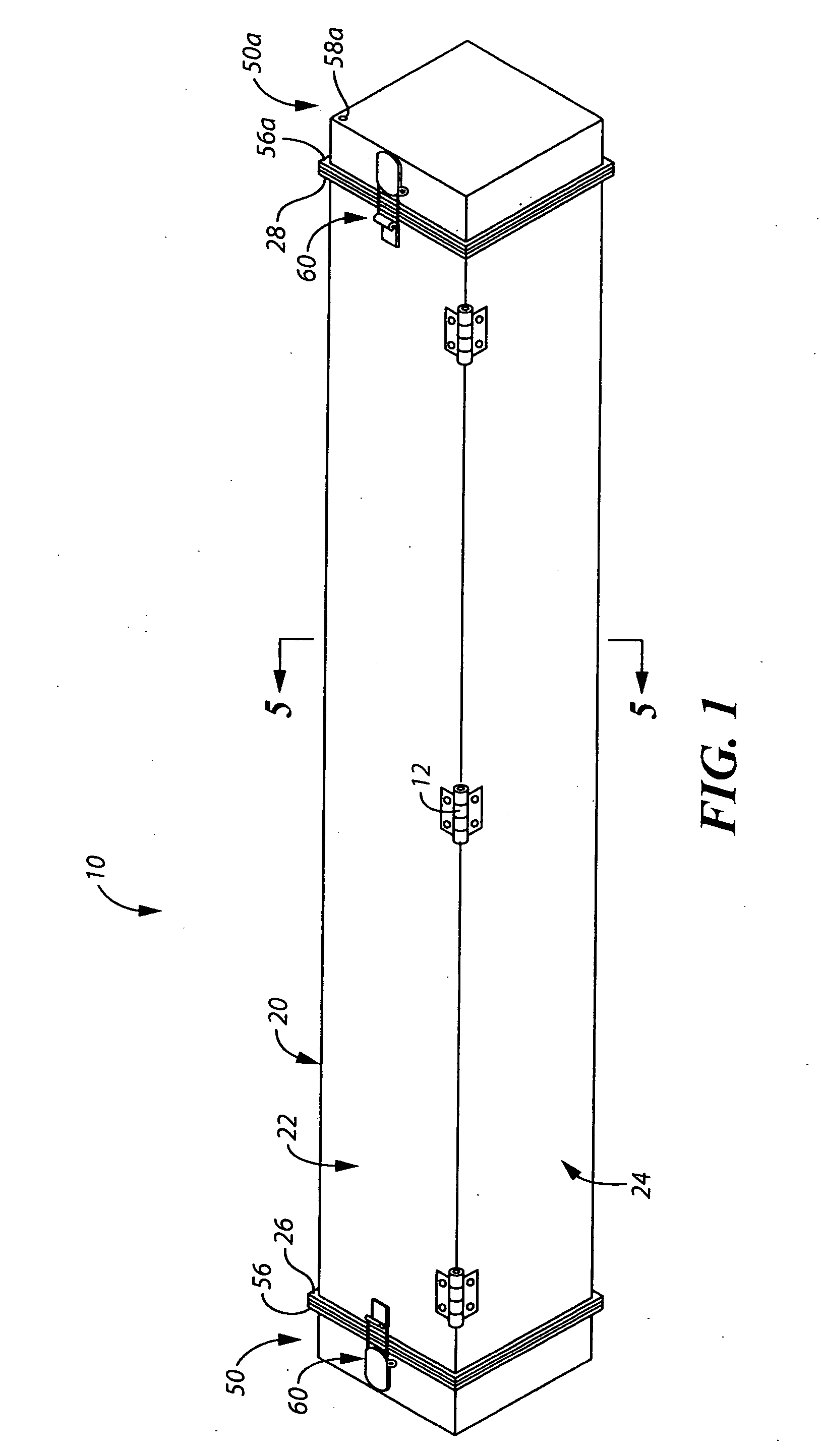

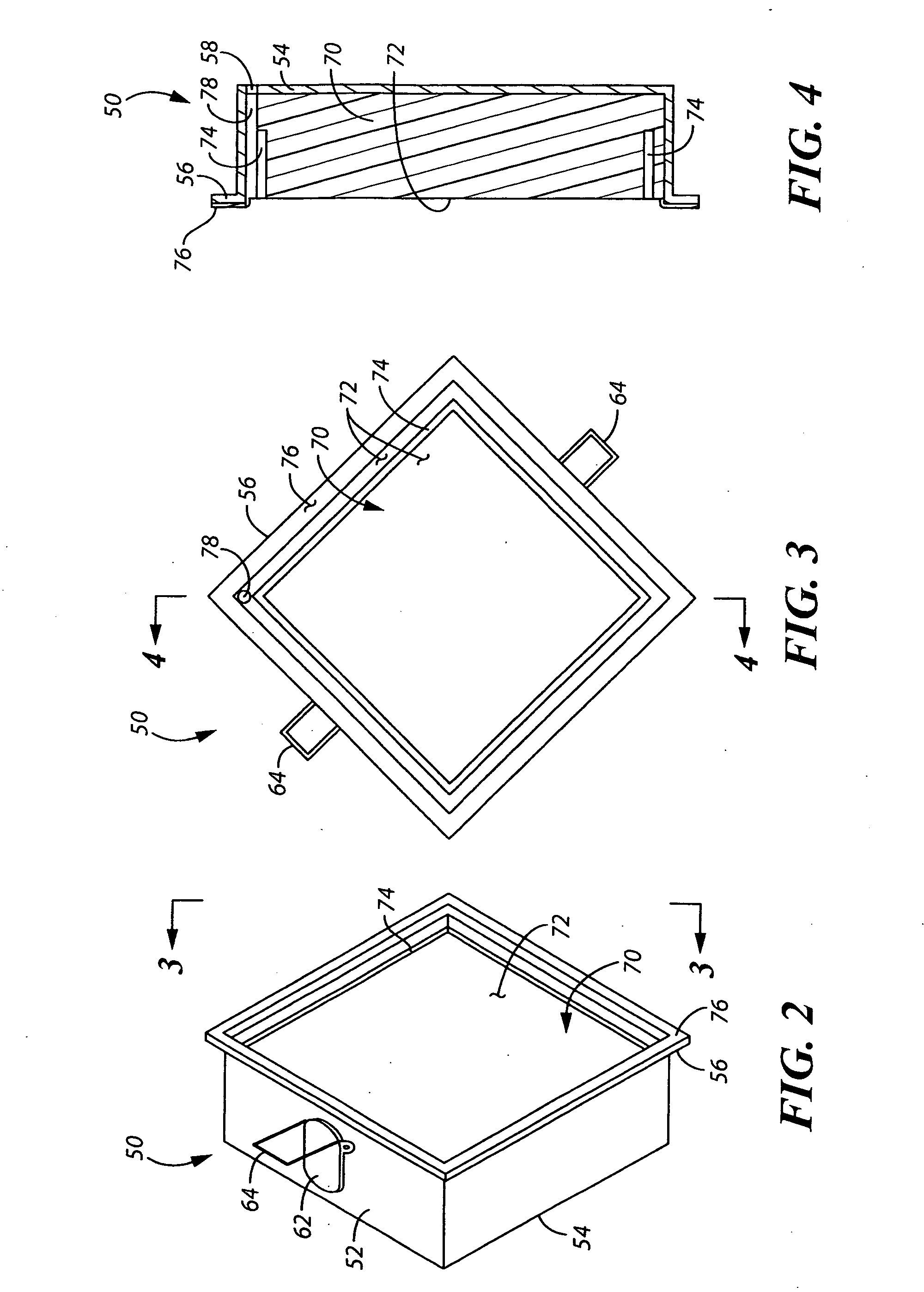

[0034]Shown throughout the figures, the present invention is generally directed to a method and apparatus for overmolding the exterior surface of a non-planar structural building component with a preferred highly-durable, Thermo-Set decorative Polyaspartic Aliphatic Polyurea overlay, as well as, Aromatic Polyurea, Aromatic Polyurethane, Unsaturated Polyester and Epoxy as to the resulting overmolded article. The preferred decorative Thermo-Set, Polyaspartic Aliphatic Polyurea overmolding is particularly fabricated to have an exposed surface simulating a non-polymeric material, such as natural wood, stone, metal, to name just a few, wherein the simulated surface has an exceptionally authentic appearance. The method is particularly well suited for use over-molding aluminum, metal, steel, iron or structural composite building components such as columns, brackets, trellises, railings, beams and the like, with a Polyaspartic Aliphatic Polyurea molding composition. However, it will be appa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com