Variable output fluid pump system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

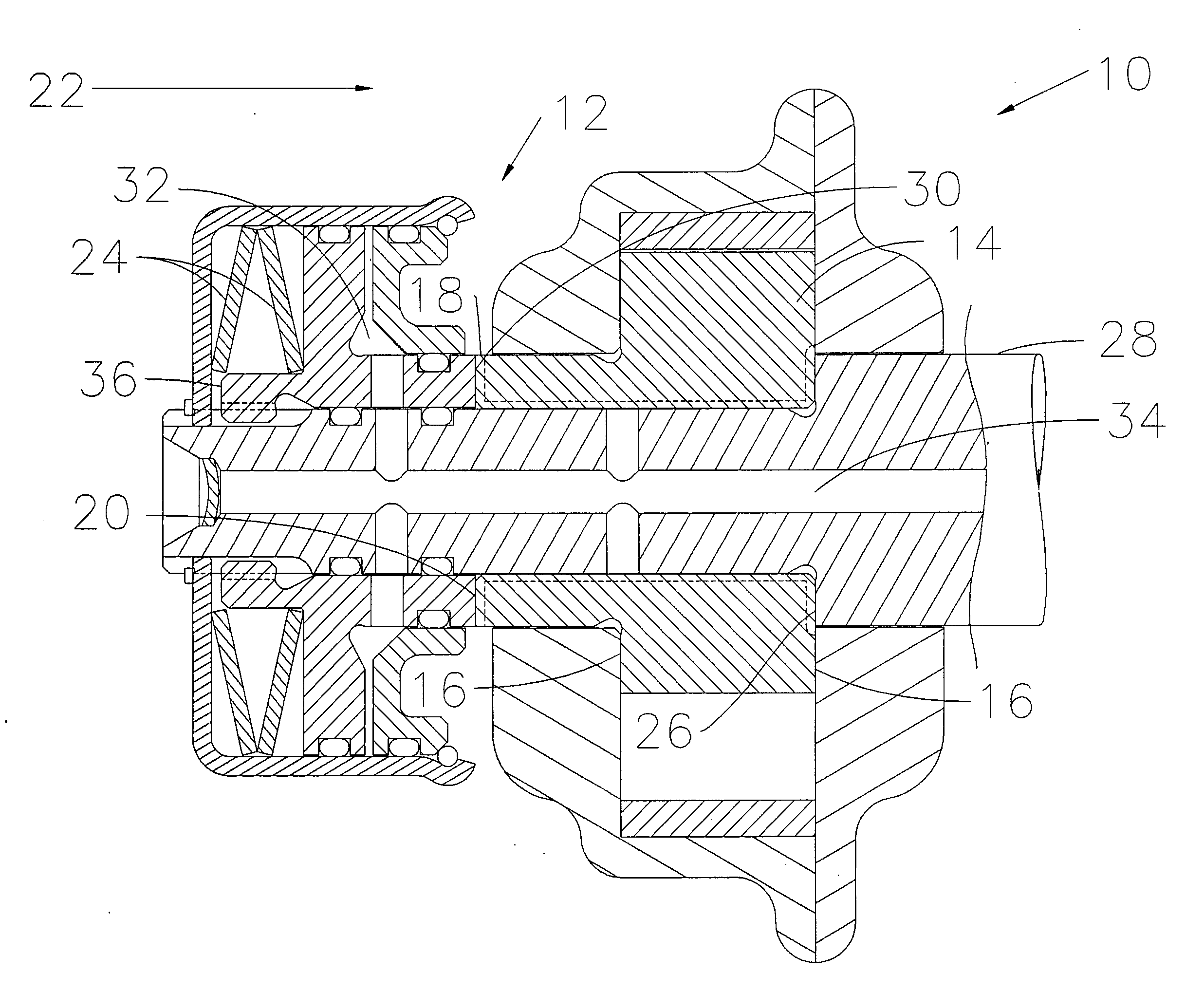

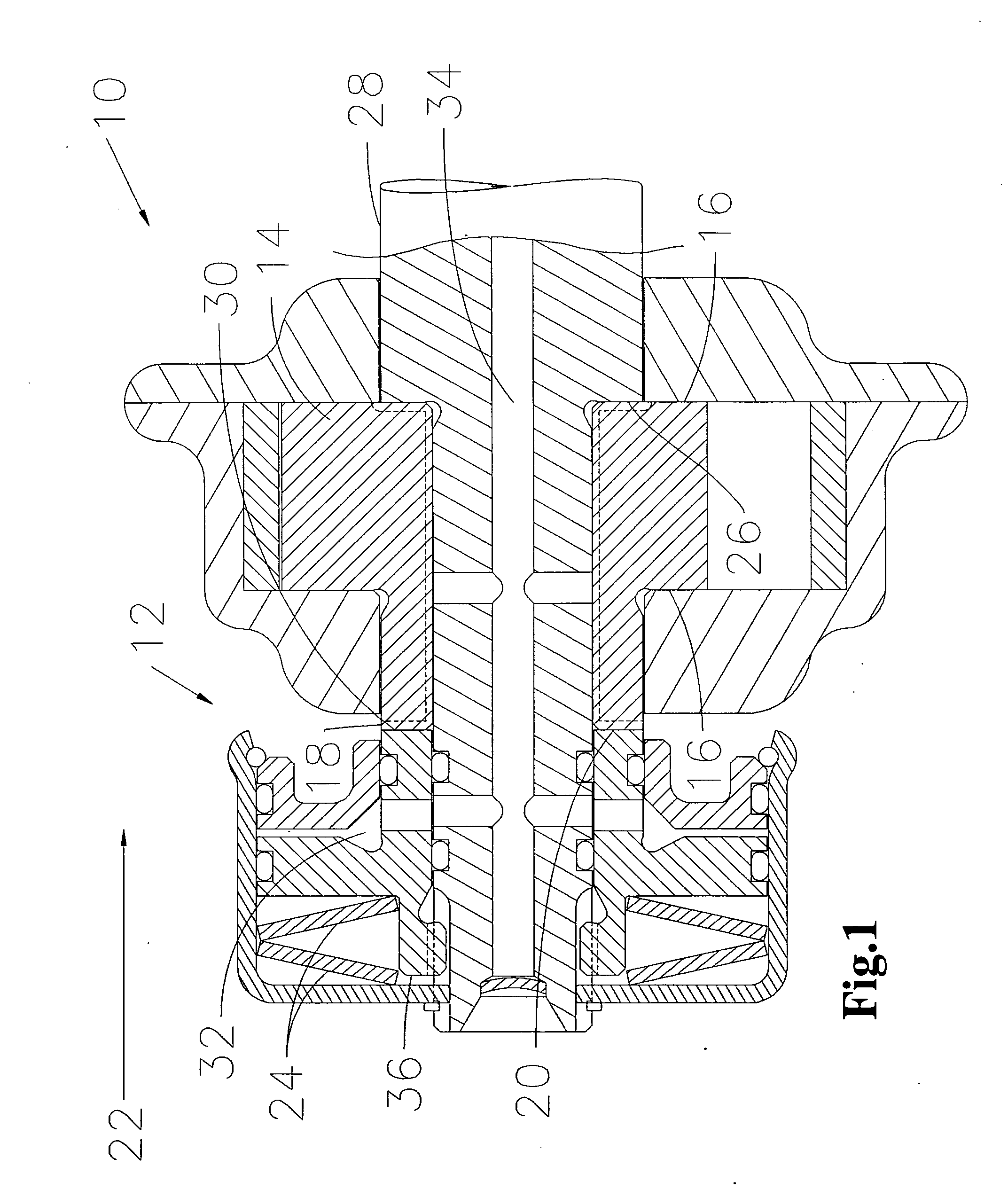

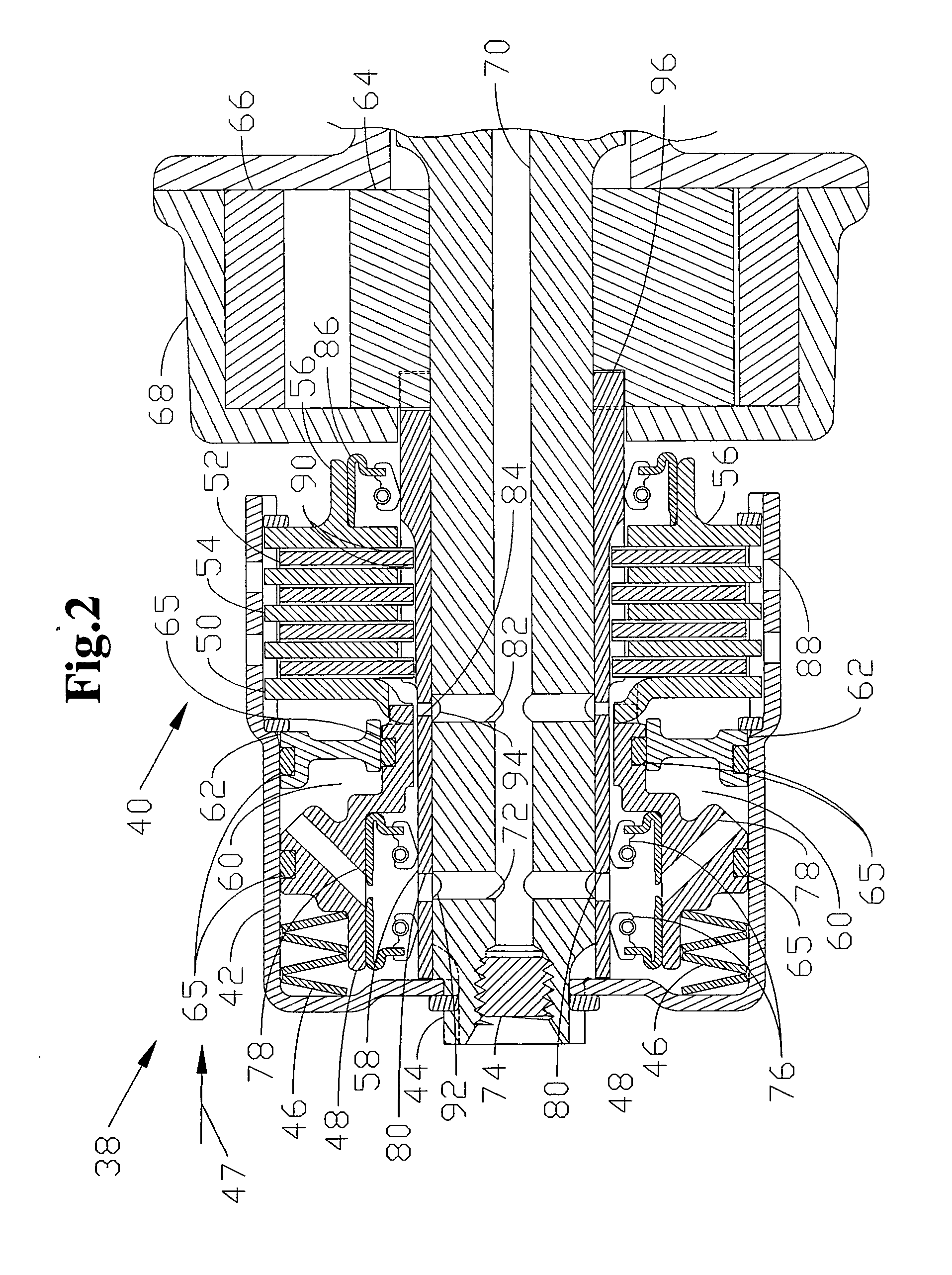

[0029]Exemplary embodiments of the present invention relate to a system comprising a low cost slip drive unit for the pressure-controlled driving of a positive displacement oil pump. The slip drive unit utilizes a predetermined axial clamping load that is applied to friction drive surfaces via a resilient biasing member (e.g., at least one Belleville disc spring or equivalents thereof). The axial clamping load is then reduced by hydraulic pressure that overcomes the biasing force of the biasing member to allow slippage of the friction drive surfaces, as needed, after a predetermined control pressure is attained, so as to limit pump speed to that which is necessary to maintain the predetermined pressure.

[0030]In one exemplary embodiment, the control pressure is taken from a remote branch of the lubrication network such as a balance shaft bearing, in order to assure that the desired pressure is available to all components downstream of the flow restrictions of, for example, those of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com