Rewinding Machine, Method for Producing Logs of Web Material

a web material and winding machine technology, applied in the direction of thin material processing, article delivery, transportation and packaging, etc., can solve the problems of web material tearing along the perforation line, high air pressure, special configuration and other problems, to achieve the effect of ensuring a high level of production flexibility, efficient and economical reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

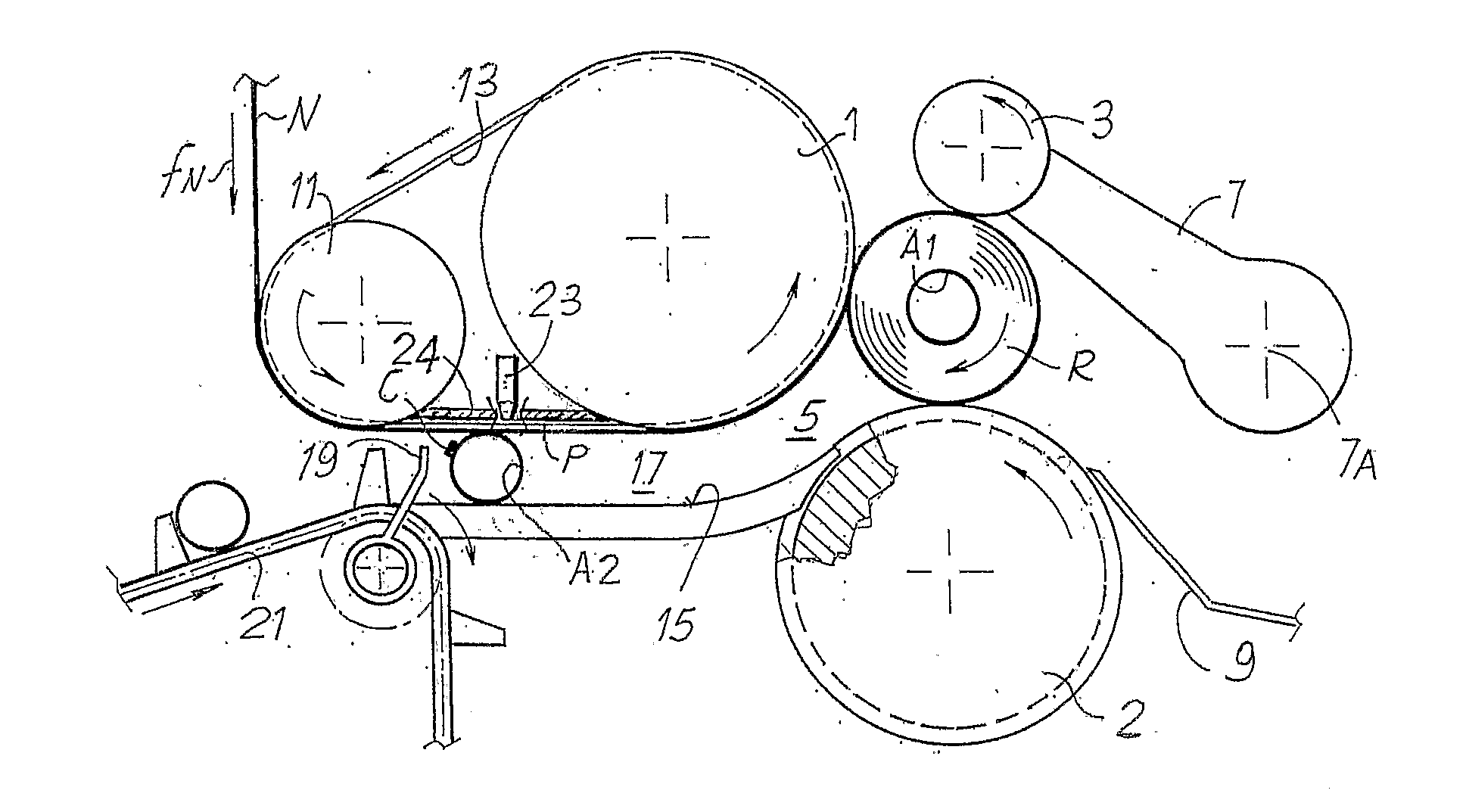

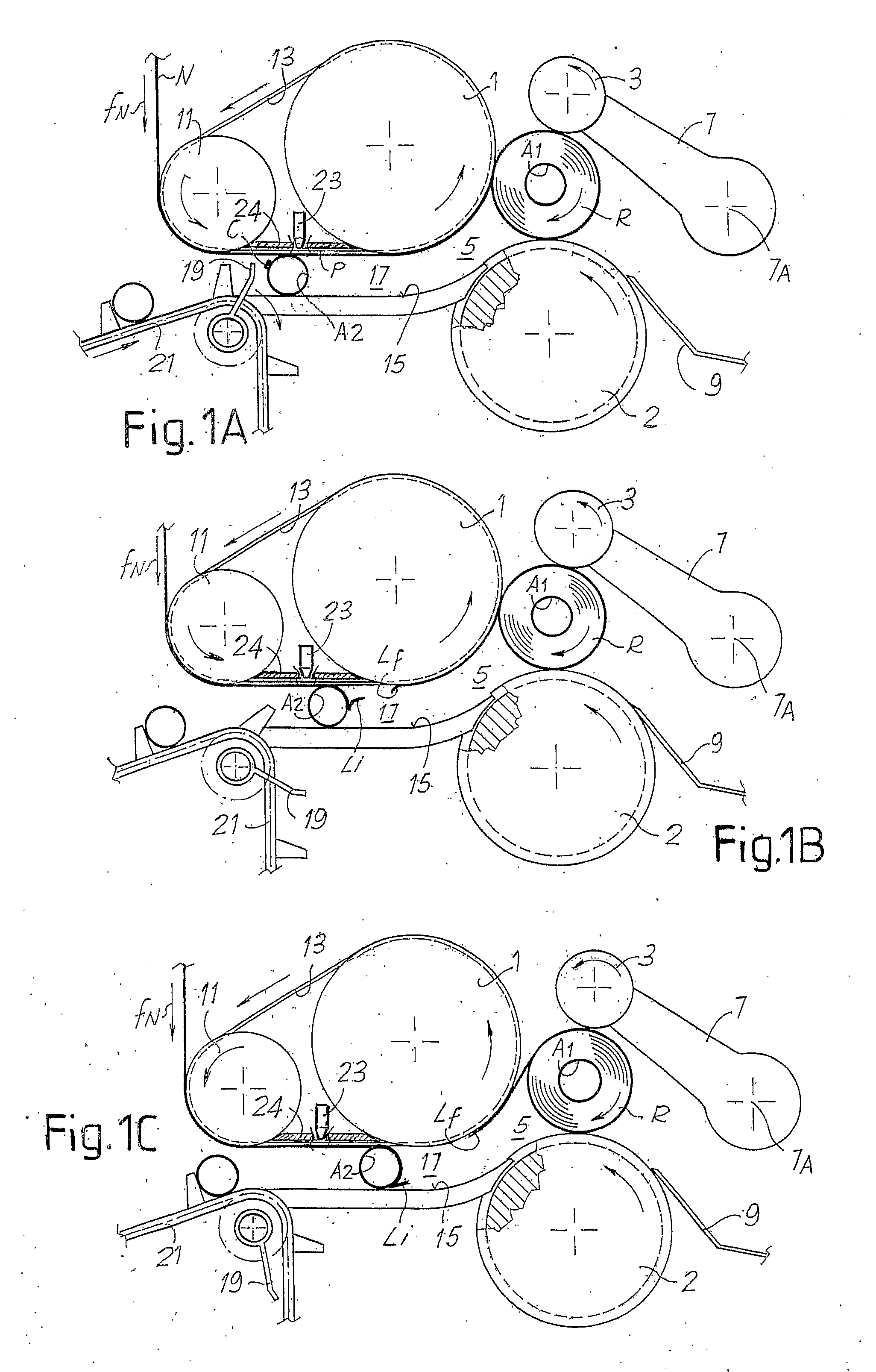

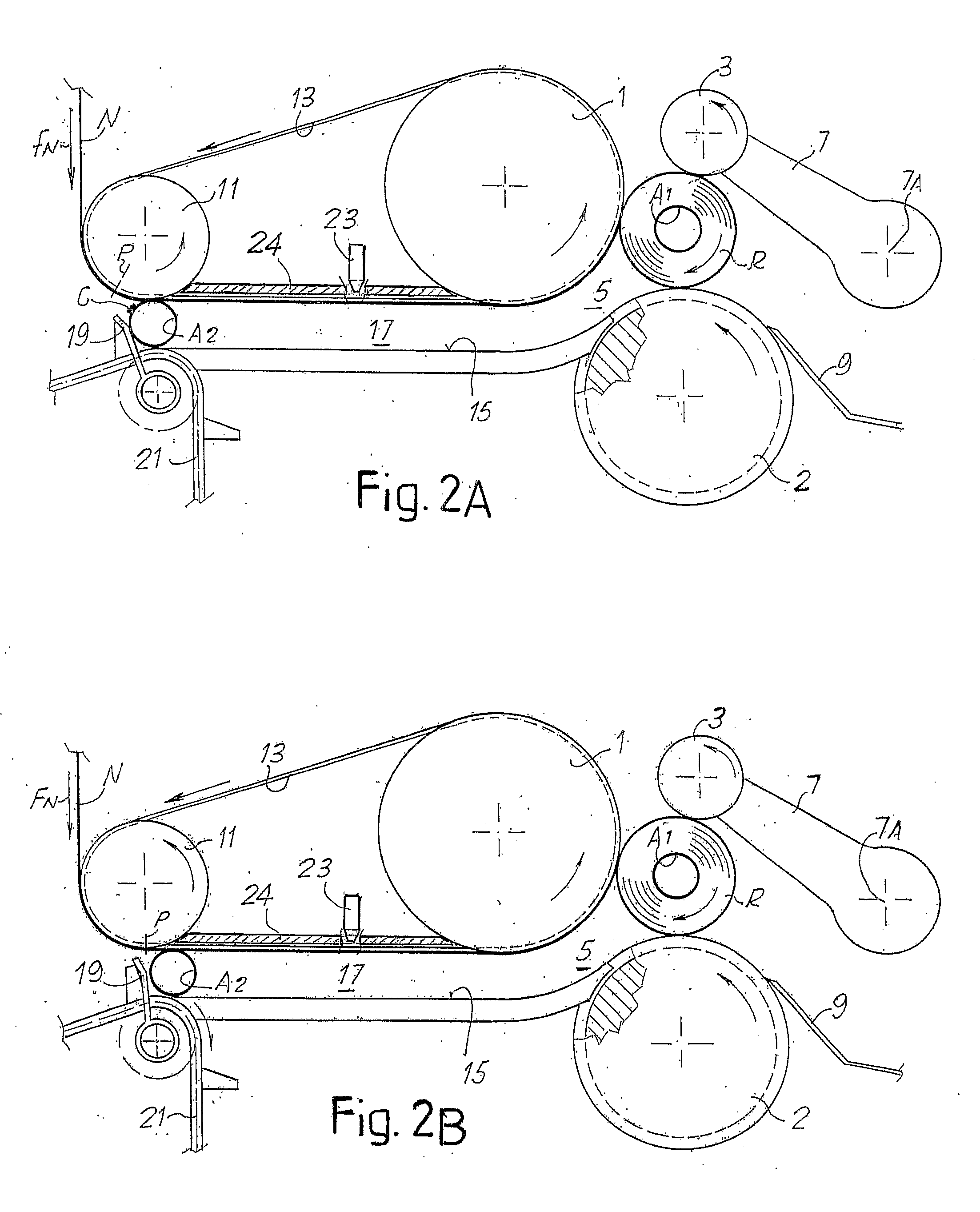

[0048]In the embodiment illustrated in FIGS. 1A, 1B and 1C, the winding machine comprises a winding cradle formed of three winding rollers and more specifically: a first winding roller 1, a second winding roller 2 and a third winding roller 3. The three rollers 1, 2, 3 rotate about axes parallel to one another and with peripheral speeds which—during the winding cycle—are substantially the same as one another, while they can vary, in a way known per se, at the end of winding to unload the completed log and / or to insert the new core, around which winding of the subsequent log has started, through a nip defined between the winding rollers 1 and 2.

[0049]The winding roller 3 is supported on a pair of oscillating arms 7, hinged about an oscillation axis 7A. The oscillating movement allows increase in the roll R being formed inside the winding cradle 1, 2, 3 and unloading of the completed roll along a chute 9.

[0050]The web material to be wound to form the logs R is indicated with N. It is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Electric charge | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com