Cysteine granules and use thereof as bifidobacterium animalis lactis growth stimulants

a technology of bifidobacterium animalis and cysteine granules, which is applied in the field of cysteine granules and use thereof as bifidobacterium animalis lactis growth stimulants, can solve the problems of difficult to achieve good compromise between the growth of technological ferments and probiotics, the quantity of activator compounds which have to be used in order to provide stimulation and the above constraints are generally very small, and the problem of difficult to

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Using Cysteine-HCl is not Suitable for the Manufacture of Granules Termed “Integrated” Granules which would Comprise both Cysteine and B. animalis lactis

Process and Apparatus

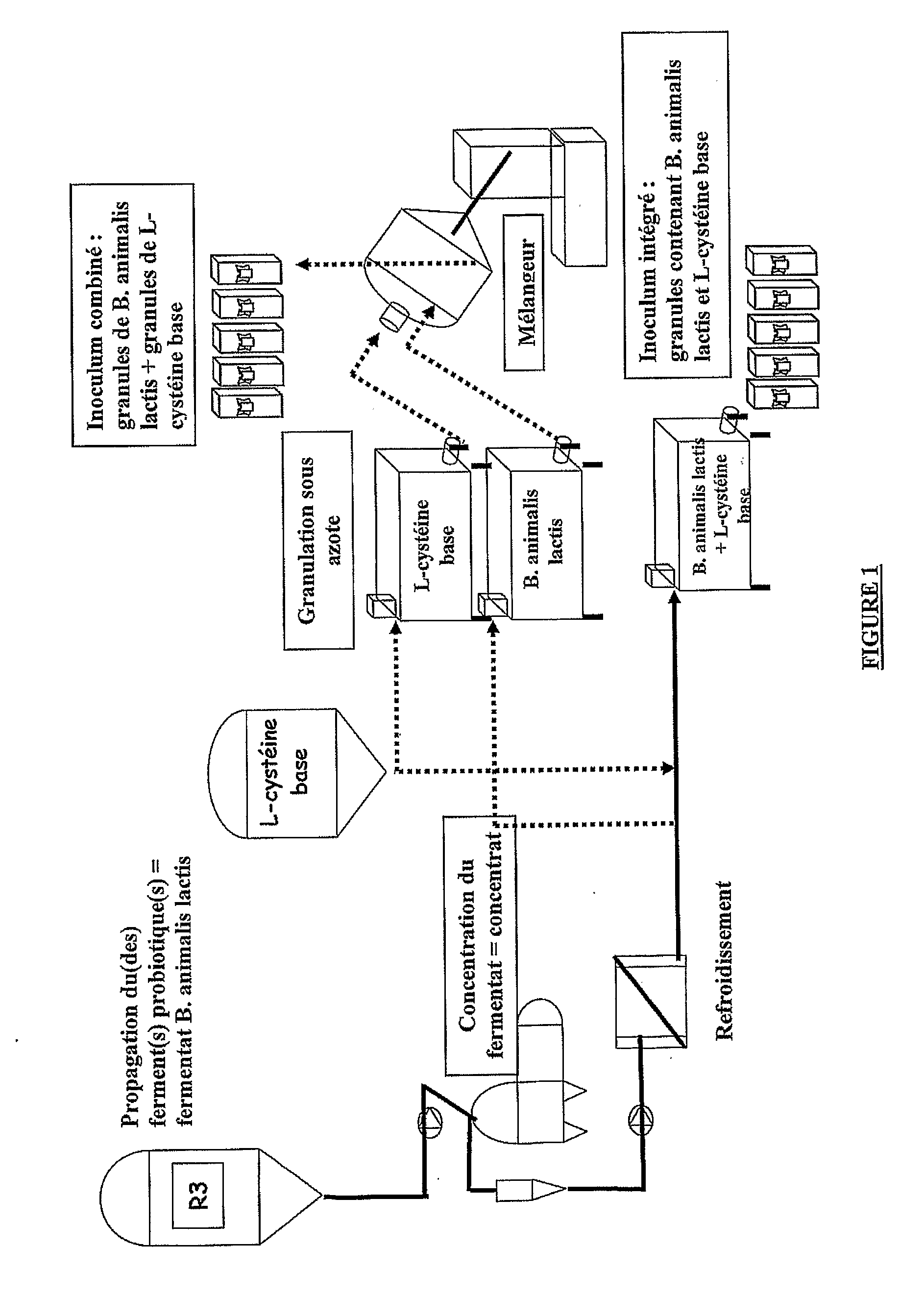

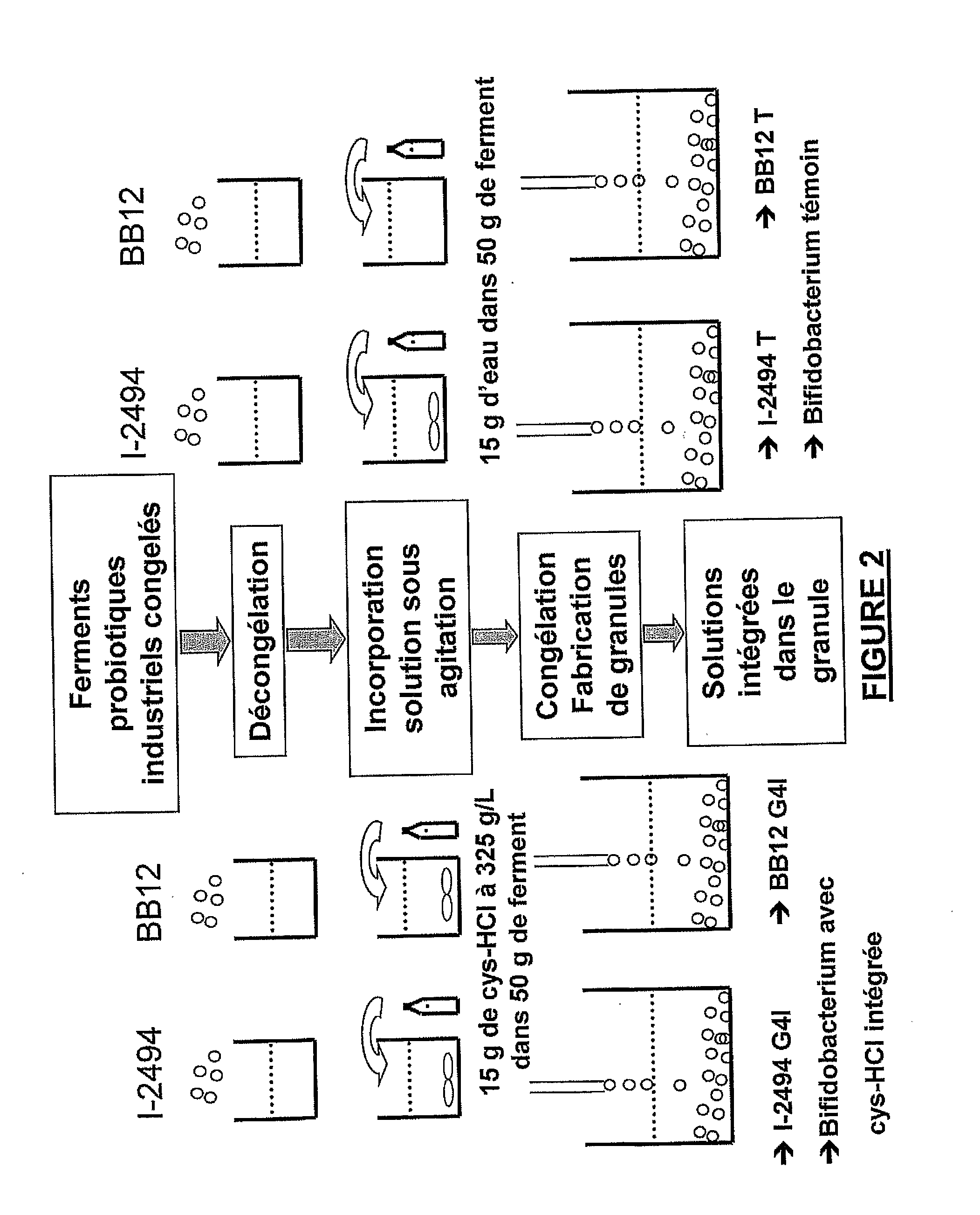

[0314]In this example, the granule manufacturing principle shown in FIG. 2 was followed.

[0315]The following probiotic strains were used in this example:[0316]Bifidobacterium animalis lactis strain BB12® (sold by Chr Hansen A / S, Hoersholm, Denmark;[0317]Bifidobacterium animalis lactis strain I-2494 available from the CNCM (date of deposit with CNCM=20 Jun. 2000); see International patent application WO-02 / 02800 filed on 4 Jul. 2001 in the name of Compagnie Gervais Danone and the national and regional counterparts of this international application; more particularly as regards the US counterparts of this international application, see U.S. Pat. No. 7,008,785.

[0318]If necessary, the strains were defrosted before use.

[0319]The cysteine used was cysteine-HCl, which is normally used to provide cysteine because of its...

example 2

Selection of an L-Cysteine Base which is Suitable for the Production of Highly Effective “Integrated” Granules Despite Problems Linked to Low Solubility of this Form of Cysteine

[0353]The procedure was comparable to that described in Example 1 above, but L-cysteine base (L-cysteine; C3H7NO2S; CAS number: 52-90-4; molar mass: 121.16) was selected instead of and in place of the cysteine-HCl.

[0354]L-cysteine base is available from Ajinomoto Aminoscience LLC, Raleigh N.C. 27610, USA.

[0355]The solubility of said cysteine base is 16 g per 100 g of H2O at 20° C.

[0356]The pH of a solution containing 1.15 g of cysteine base per 50 mL of H2O is 4.5 to 5.5.

[0357]A stock solution was prepared containing 160 g / L of cysteine base and 3 grams of this stock solution was mixed with 10 grams of B. animalis lactis ferment (B. animalis lactis strain I-2494 or strain BB12®) which was formulated into frozen granules (I-2494 G4I Cys-base; and BB12 G4I Cys-base) as described in Example 1 above.

[0358]Referen...

example 3

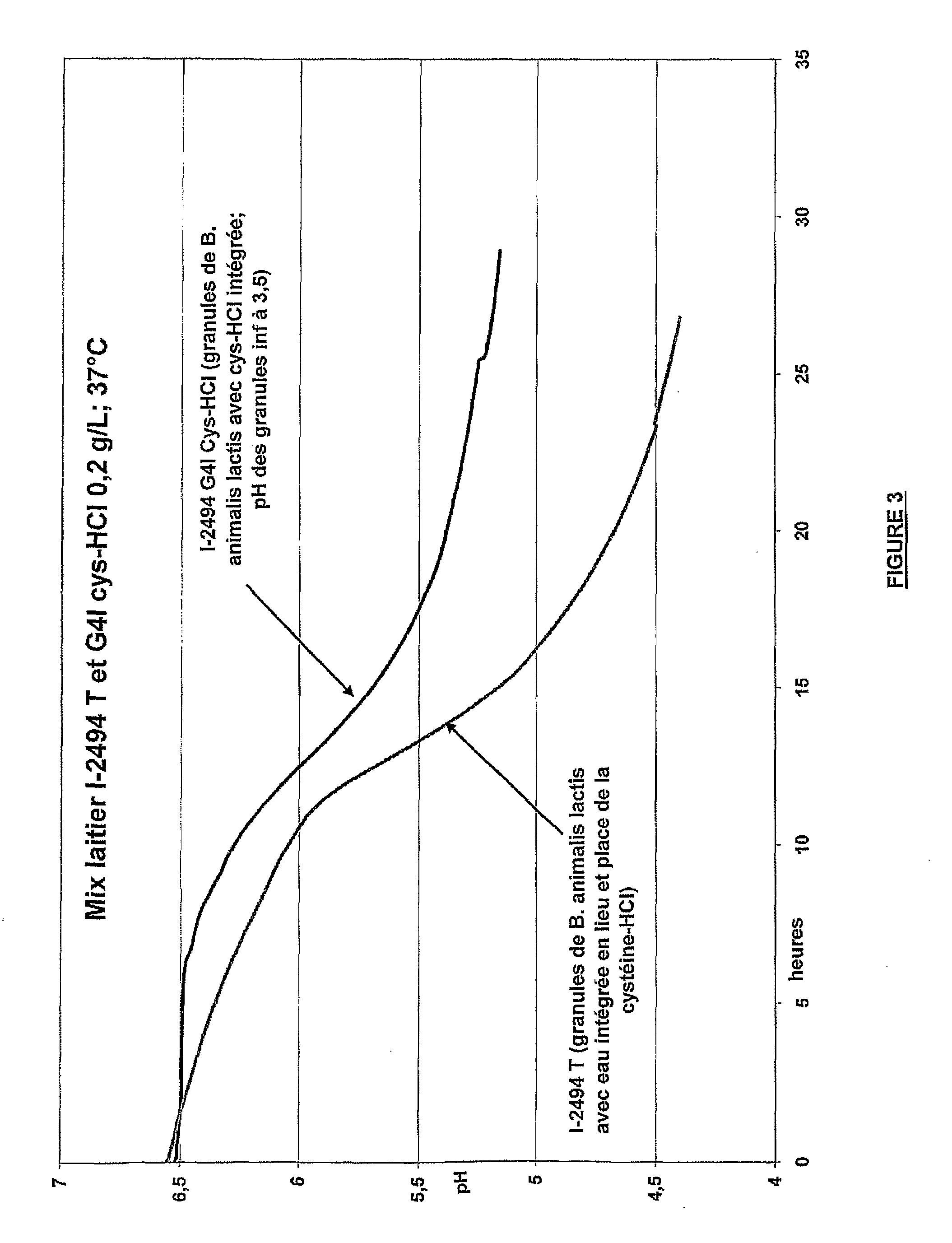

Performance of Integrated G4I Cys-Base System Firstly Compared with the Combined G4 System (Cysteine Granules Distinct from Probiotic Ferment Granules) and Secondly Compared with a Reference System (T Granules, No Cysteine)

[0369]In this example, granules of B. animalis lactis ferment produced as described in Example 2 were used, namely:[0370]BB12 T granules (reference granules containing B. animalis lactis BB12®+water);[0371]BB12 G4I granules (integrated granules containing B. animalis lactis BB12®+L-cysteine base in a concentration of approximately 1.85 mg of L-cysteine, C3H7NO2S, per billion cfu of probiotic ferment);[0372]I-2494 T granules (reference granules containing B. animalis lactis I-2494+water); and[0373]I-2494 G4I granules (integrated granules containing B. animalis lactis I-2494+L-cysteine base in an amount of approximately 1.85 mg of cysteine, C3H7NO2S, per billion cfu of probiotic ferment).

[0374]In this example, ferments termed technical ferments were also used; they ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com