Solenoid valve for brake system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]Reference will now be made in detail to the embodiment of the present invention, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout.

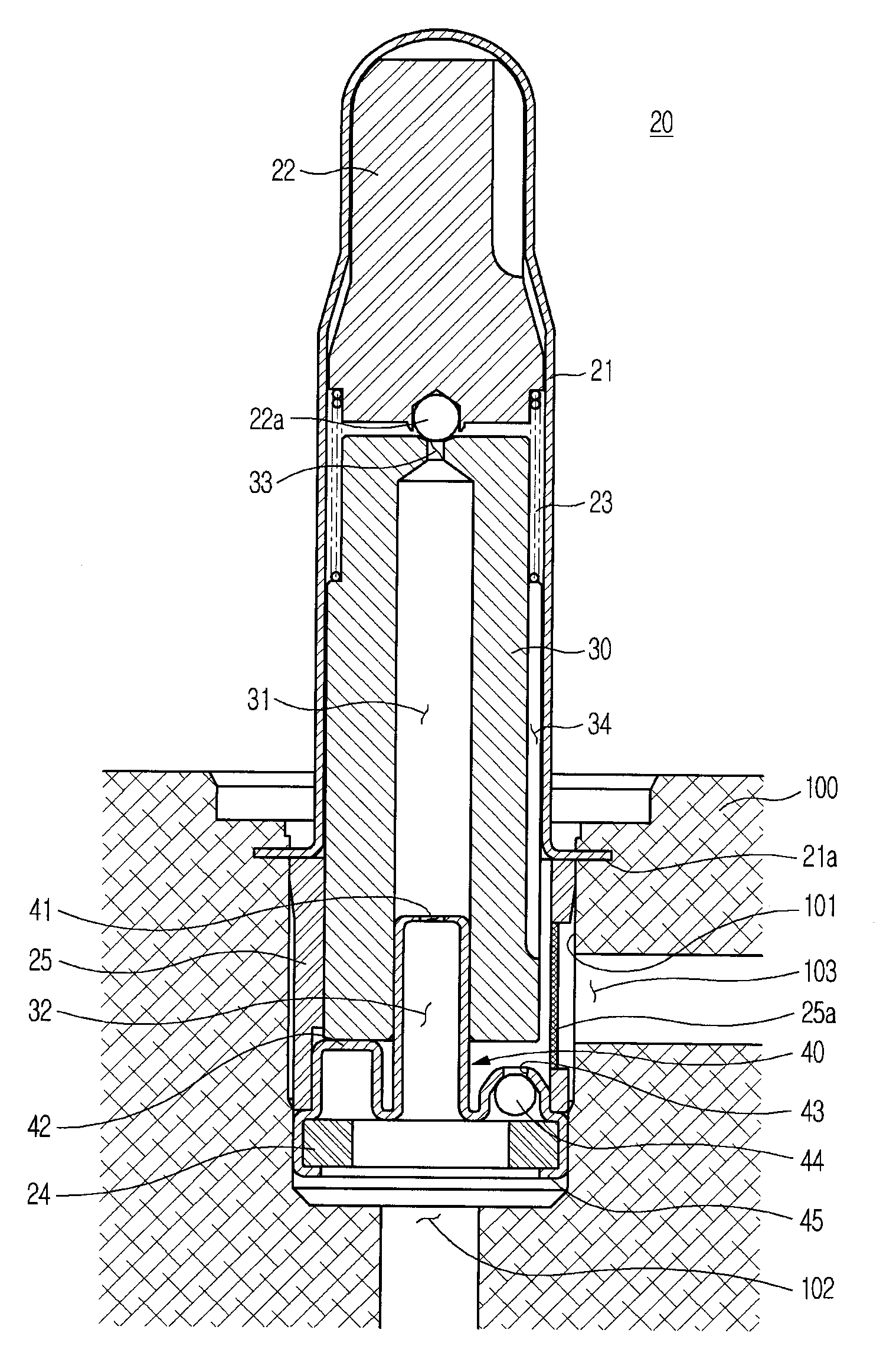

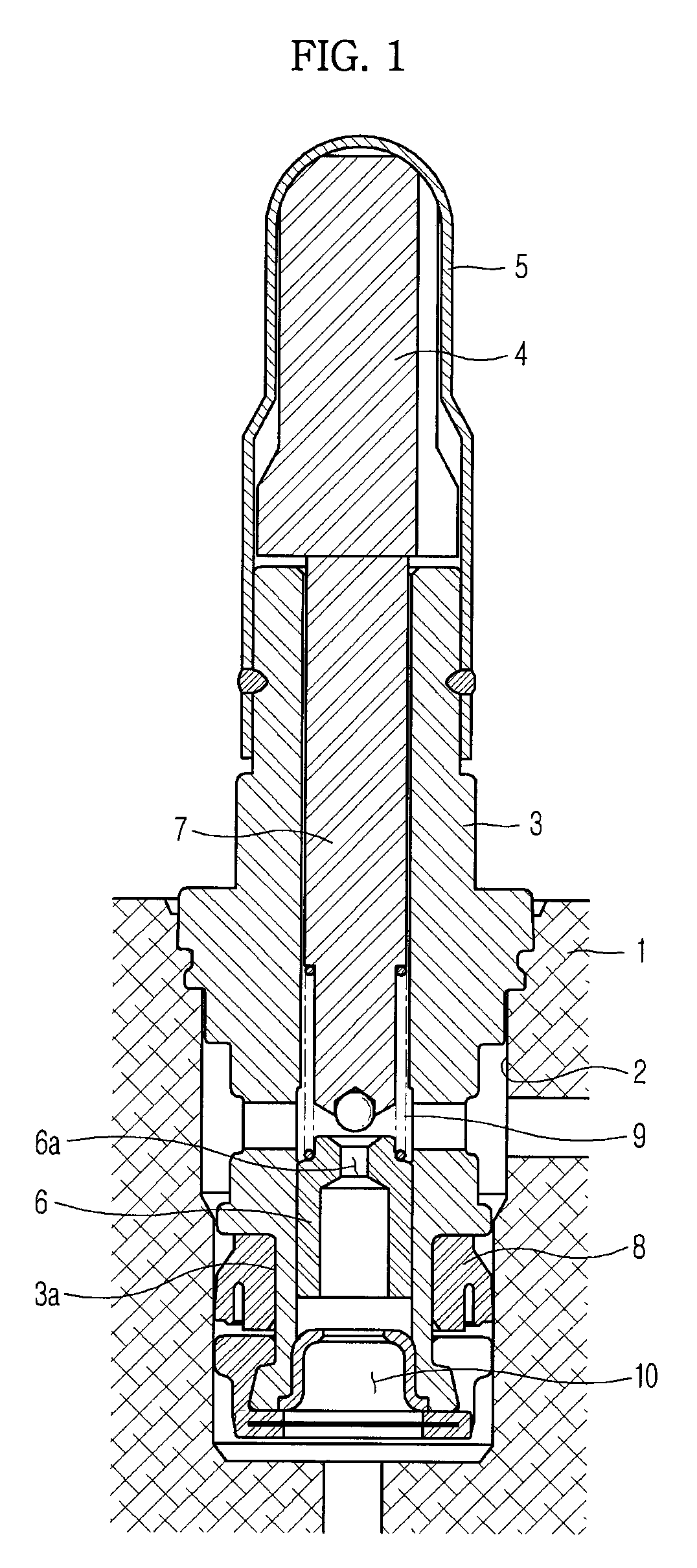

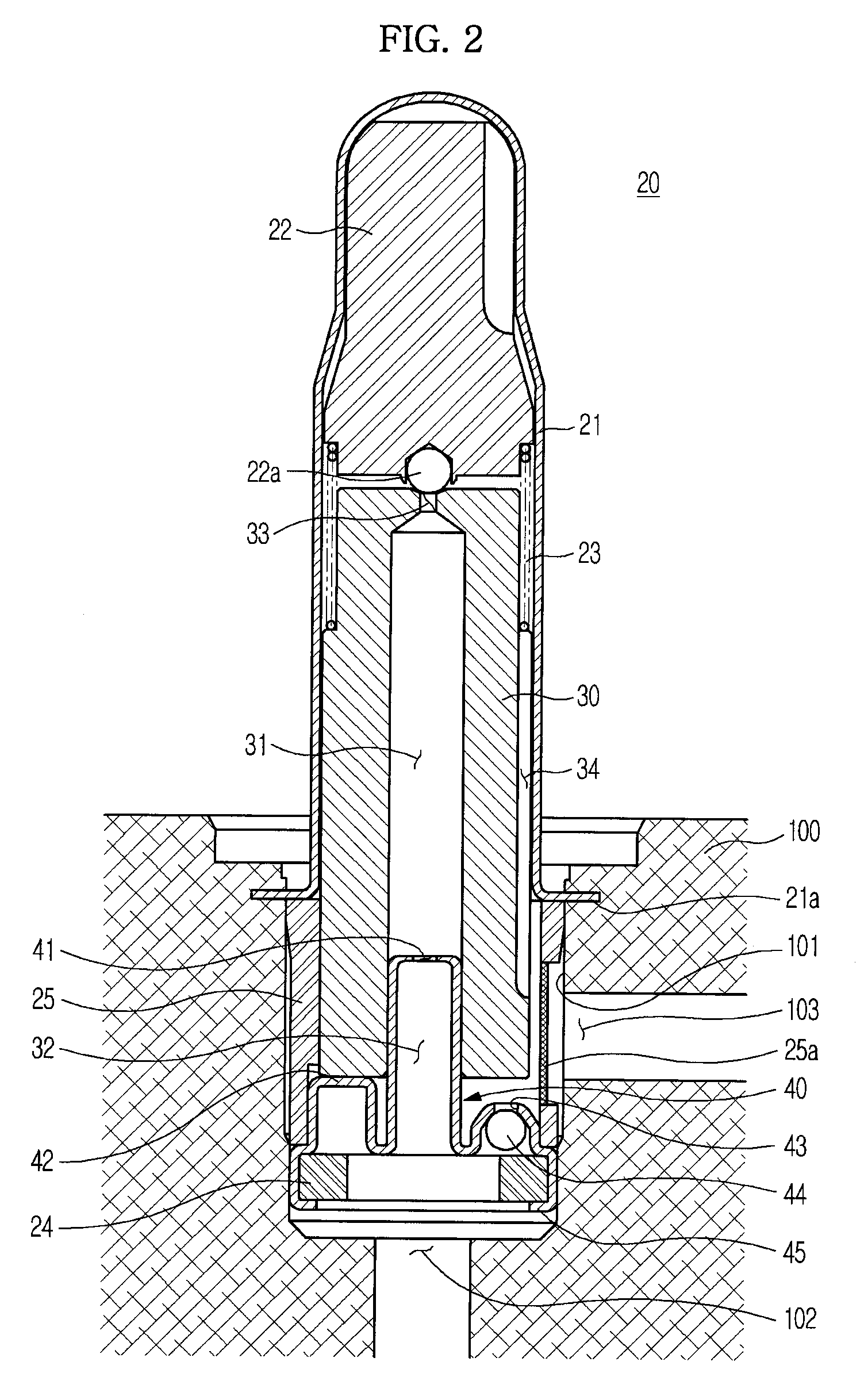

[0029]Referring to FIG. 2, a valve 20 for a brake system according to the present embodiment is installed in a bore 101 formed in a modulator block 100 in the form of a hexahedral block. An inlet 102 is provided below the bore 101 and is connected to a master cylinder (not shown) to receive oil from the master cylinder. Also, an outlet 103 is provided at a side of the bore 101 and is connected to a brake (not shown) to transmit the oil to the brake.

[0030]In the present embodiment, the shown valve 20 is a normally opened type solenoid valve and thus, is normally kept in an opened state but closes a flow-path upon receiving power.

[0031]The valve 20 includes a cylindrical sleeve 21 having an inner hollow, an armature 22 movably received in the sleeve 21, a magnet core 30 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com