Unitary light guide plate, light guide plate unit, planar lighting device and liquid crystal display device

a technology of light guide plate and light guide plate, which is applied in the direction of lighting and heating apparatus, instruments, mechanical instruments, etc., can solve the problems of difficult to achieve the irregular light amount of a backlight unit having a thickness of 10 mm or less, and achieve the effect of improving light emission efficiency, reducing cost, and reducing the thickness of the backlight uni

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

third embodiment

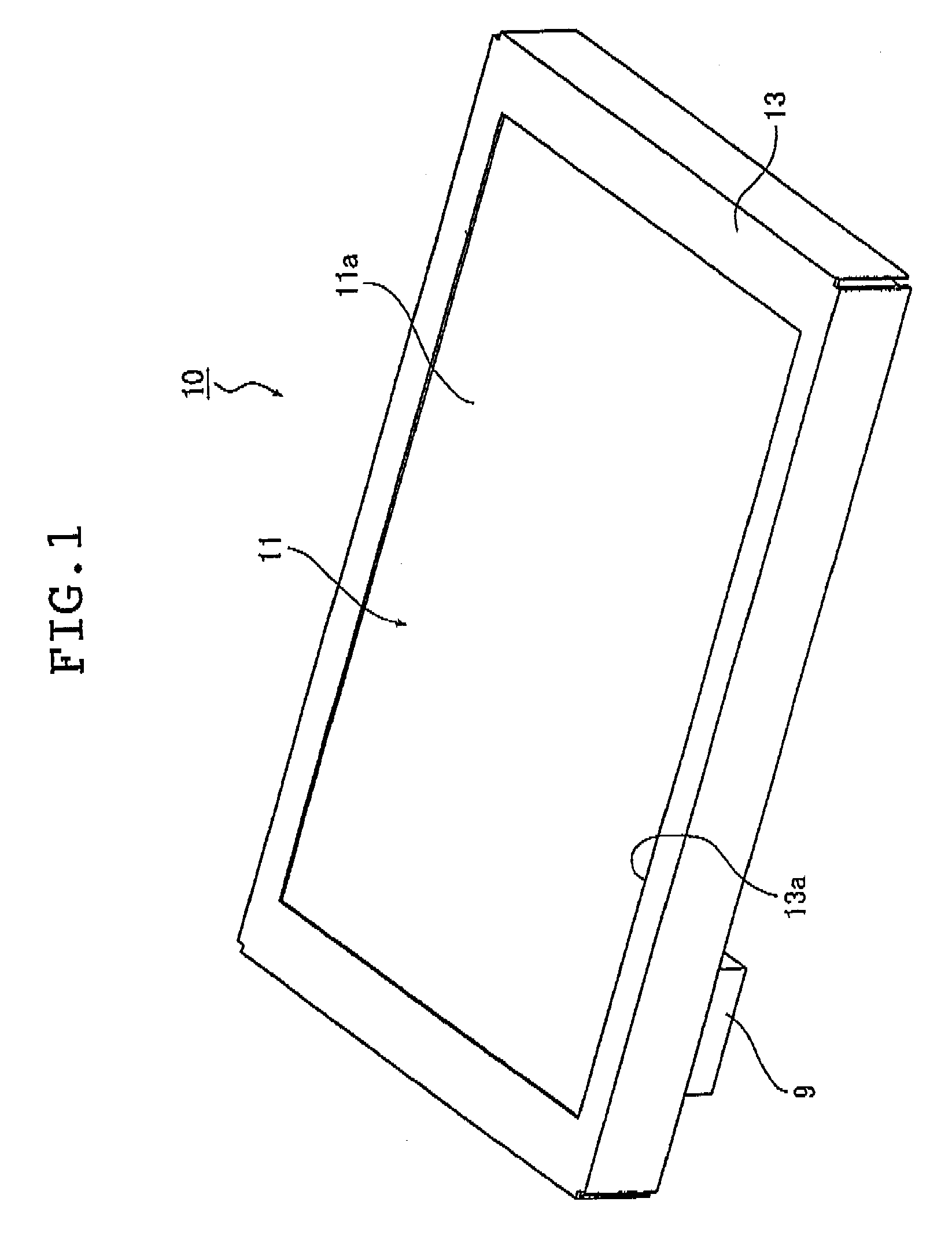

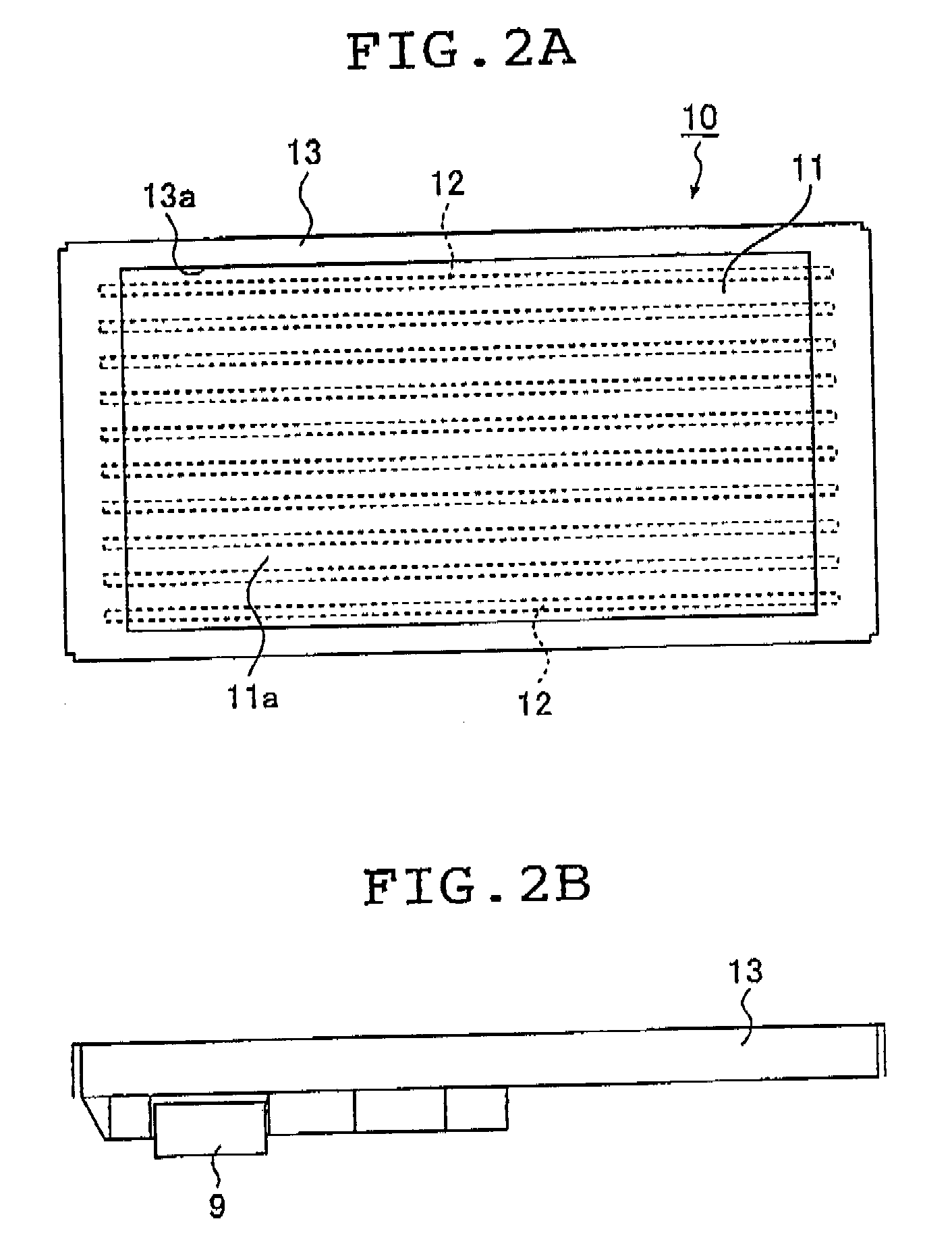

[0165]FIG. 1 is a schematic perspective view illustrating the exterior of the planar lighting device according to the present invention, which is a first aspect of the present invention, seen from a light exit plane side. FIGS. 2A, 2B, 2C and 2D are each a front view, a bottom view, a lateral view, and a rear view of the planar lighting device illustrated in FIG. 1. In the following drawings including these drawings, the planar lighting device is illustrated under magnification in a thickness direction thereof for ease of understanding.

[0166]As illustrated in FIG. 1 and FIGS. 2A to 2D, a planar lighting device 10 includes a lighting device main body 11 including a plurality of linear light sources 12 and emitting uniform light from a rectangular light exit plane 11a, a housing 13 accommodating the lighting device main body 11 therein and including a rectangular opening 13a on a side of the light exit plane 11a (surface side), an inverter accommodating portion 9 provided on a side of...

first embodiment

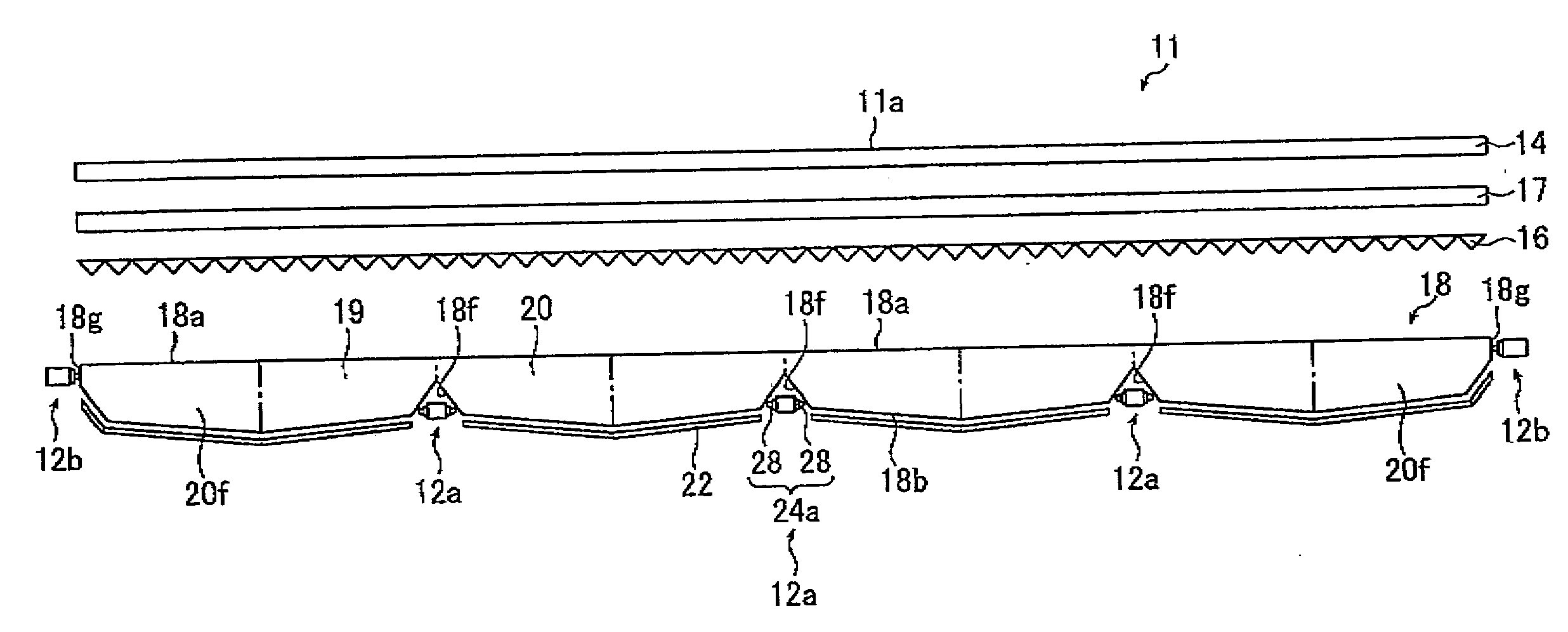

[0168]The lighting device main body 11 is for emitting uniform light from a rectangular light exit plane 11a, and basically configured, as illustrated in FIG. 3, so as to form a rectangular light exit plane 18a on the light exit plane 11a side by coupling a plurality of linear light sources 12 and a plurality of unitary light guide plates 19 or 20 of the first aspect of the present invention in parallel, and includes a light guide plate unit 18 having a plurality of parallel grooves 18f formed on the backside of the light exit plane 18a to accommodate the linear light sources 12, two prism sheets 16 and 17 arranged on the light exit plane 18a side of the light guide plate unit 18, and a diffusion sheet 14.

second embodiment

[0169]Note that, as illustrated in FIG. 3, the lighting device main body 11 is constituted of the light guide plate unit 18 of the first aspect of the present invention, and needless to say, the two prism sheets 16 and 17 and the diffusion sheet 14 arranged over the light guide plate unit 18 all have sizes (areas) substantially equal to that of the light exit plane 18a of the light guide plate unit 18.

[0170]The coupling of the unitary light guide plates 19 and 20 of the first embodiment of the first aspect of the present invention constituting the light guide plate unit 18 described above, and the coupling of the unitary light guide plates 19 or 20 for constituting the light guide plate unit 18 are described below in detail.

[0171]In FIG. 3, the linear light source 12 includes linear light sources 12a disposed in the parallel grooves 18f formed in the light guide plate unit 18 for emitting light from both sides toward the opposing wall planes of the parallel groove 18f, and linear li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com