Heat exchanger unit

a heat exchanger and semiconductor technology, applied in the direction of semiconductor devices, lighting and heating apparatus, basic electric elements, etc., can solve the problems of increasing the thermal resistance, reducing so as to improve optimize the heat conduction effect. , the effect of small surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0046]As illustrated in FIG. 5, a heat exchanger unit given with a flow path 12 for refrigerant, formed so as to allow the refrigerant to pass over a flat plate 7 provided with a surface-modified portion, is manufactured. The heat exchanger unit has a heating element 6, and a heat exchanger block 10 provided over the heating element 6. The heat exchanger block 10 has a heat exchanger upper holder 11 and a modified surface 7. The heat exchanger upper holder 11 is provided with an inlet 8 and an outlet 9, allowing therethrough introduction and discharge of a liquid refrigerant, respectively. Inside the heat exchanger block 10, there is provided the flow path 12 allowing therethrough circulation of a liquid refrigerant. Since the flow path 12 is provided so as to allow the refrigerant to pass over the modified surface 7, the flow rate of the refrigerant may be varied, making it possible to avoid adverse effects such as dry-out ascribable to generation of a large amount of bubbles.

example 2

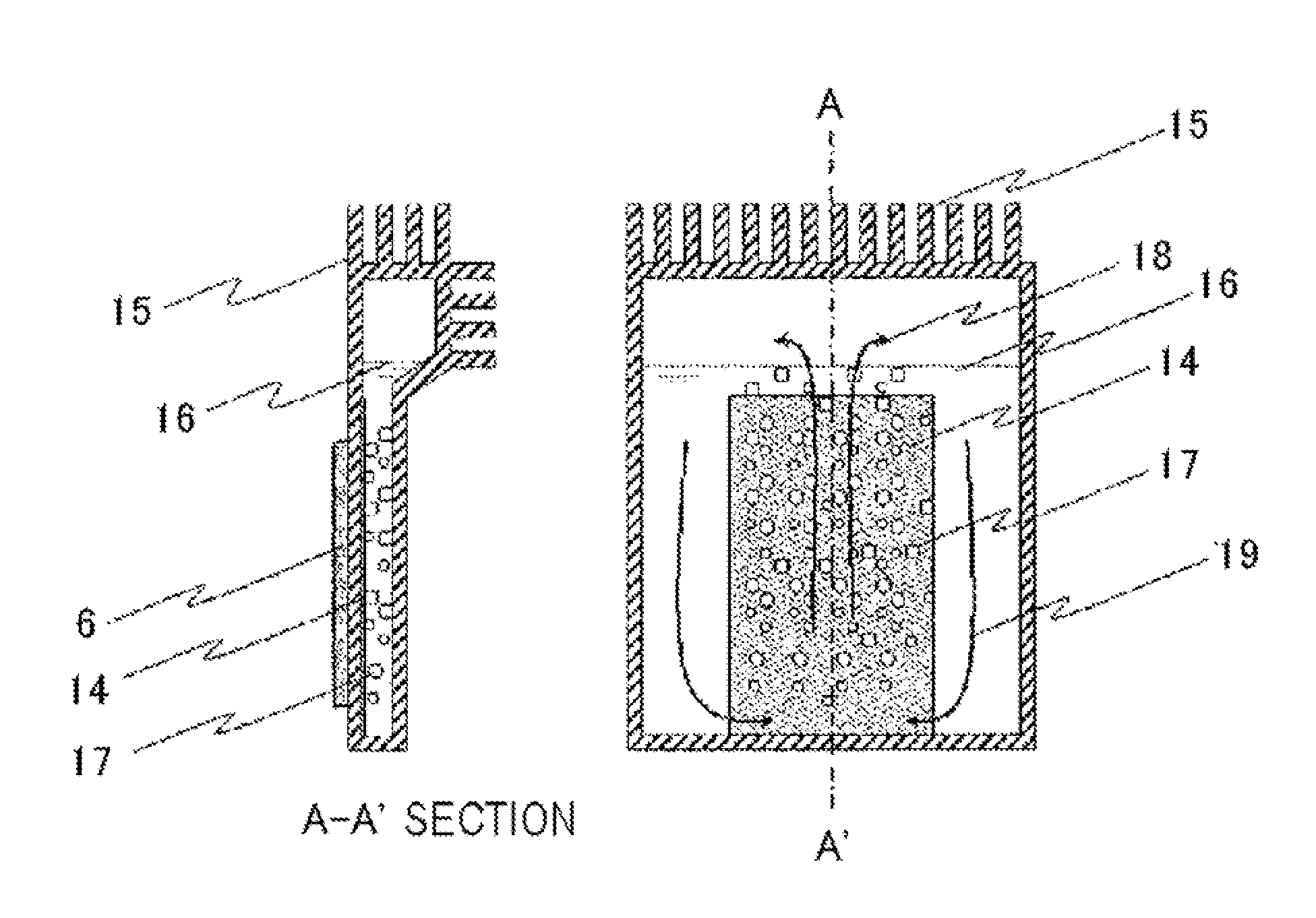

[0047]The heat conduction surface provided with the surface-modified portion may be used under pool boiling, while needing a mode capable of avoiding the dry-out. One possible method may be such as selectively providing a surface-modified portion 14, rather than providing it over the entire surface of the heat conduction surface 13. For example, as illustrated in FIG. 6, the surface-modified portion 14 may possibly be provided only at around the center of the heat conduction surface 13, so as to induce natural convection.

[0048]The number of convection cells on the flat plate is an issue of the Rayleigh-Benard Convection problem, and is determined by a function of the depth of refrigerant and the area of the bottom surface. In this Example, by selectively providing surface-modified portion 14 while making use of the convection cells, the boiling bubbles may effectively be taken apart from the heat conduction surface soon after dissociation, and thereby the liquid may be supplied to t...

example 3

[0049]The surface-modified portion of the present invention may be adoptable also to a heat conduction portion having a form generally called micro-channel, among forced-convection boiling refrigerant type cooling units, aimed at achieving a heat conduction effect by forming fine flow paths (FIG. 7). The micro-channel limits the width of the flow path to as small as the size of the boiling bubbles or below, in order to extremely expand the contact area between the heat conduction surface and a refrigerant. As a consequence, the bubbles may stagnate and the flow may accordingly be unbalanced among the flow paths, depending on refrigerant and conditions of flow.

[0050]By providing the surface modification of the present invention, the boiling bubbles may be allowed to generate uniformly in the flow paths, and may therefore be reduced in size when they dissociate from the heat conduction surface. Since small bubbles are unlikely to stagnate, so that the flow may more readily be balanced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com