Mono-silicon solar cells

a solar cell and monosilicon technology, applied in the field of photovoltaics (pv) technology, can solve the problems of shortening the lifetime of electrons, and limiting the energy conversion efficiency of mono-silicon solar cells made from b-doped p-type substrates in massive production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

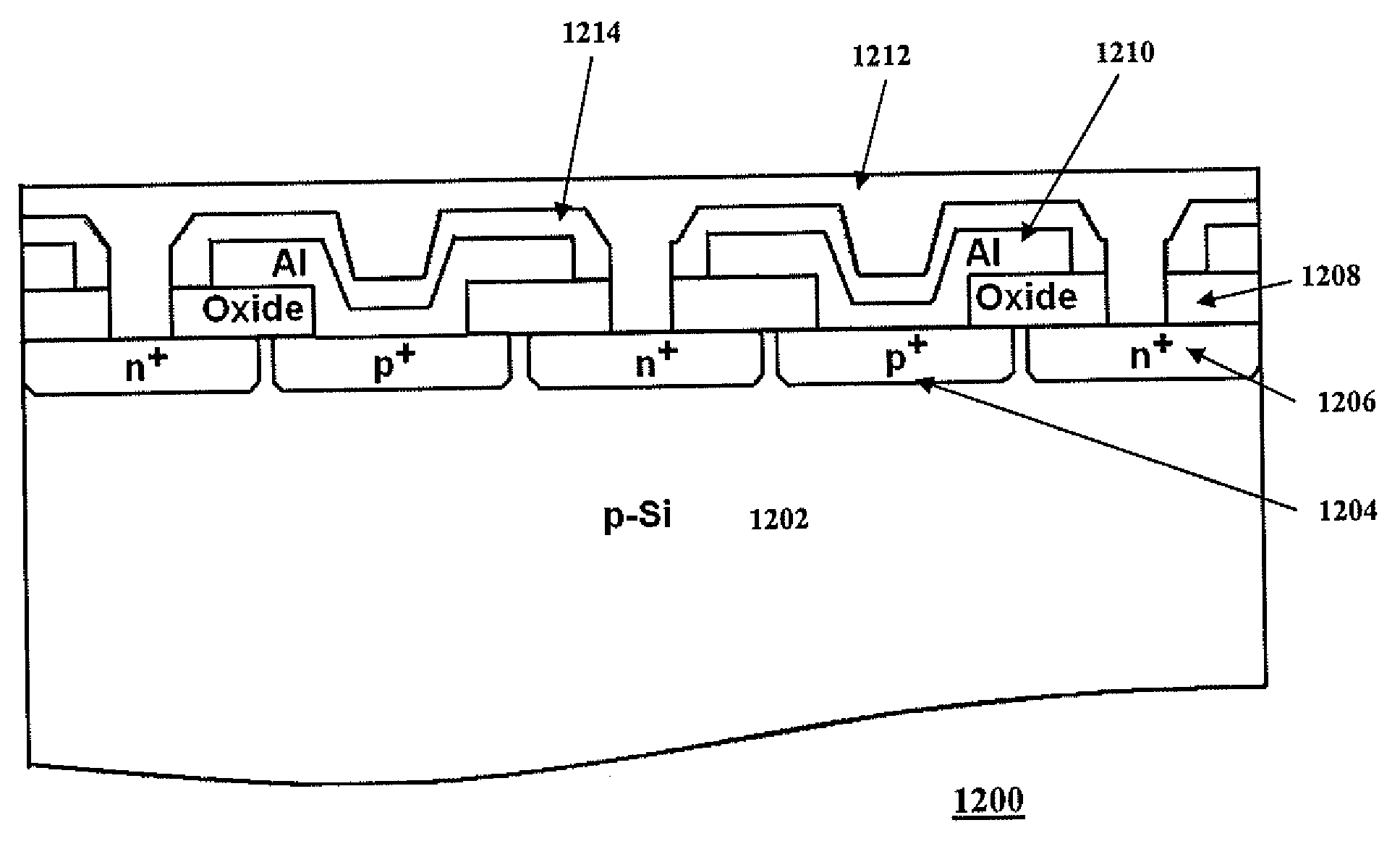

[0020]Disclosed herein are schemes designed to achieve maximum solar conversion efficiency for electricity power extraction from solar cells made from mono-Si substrates.

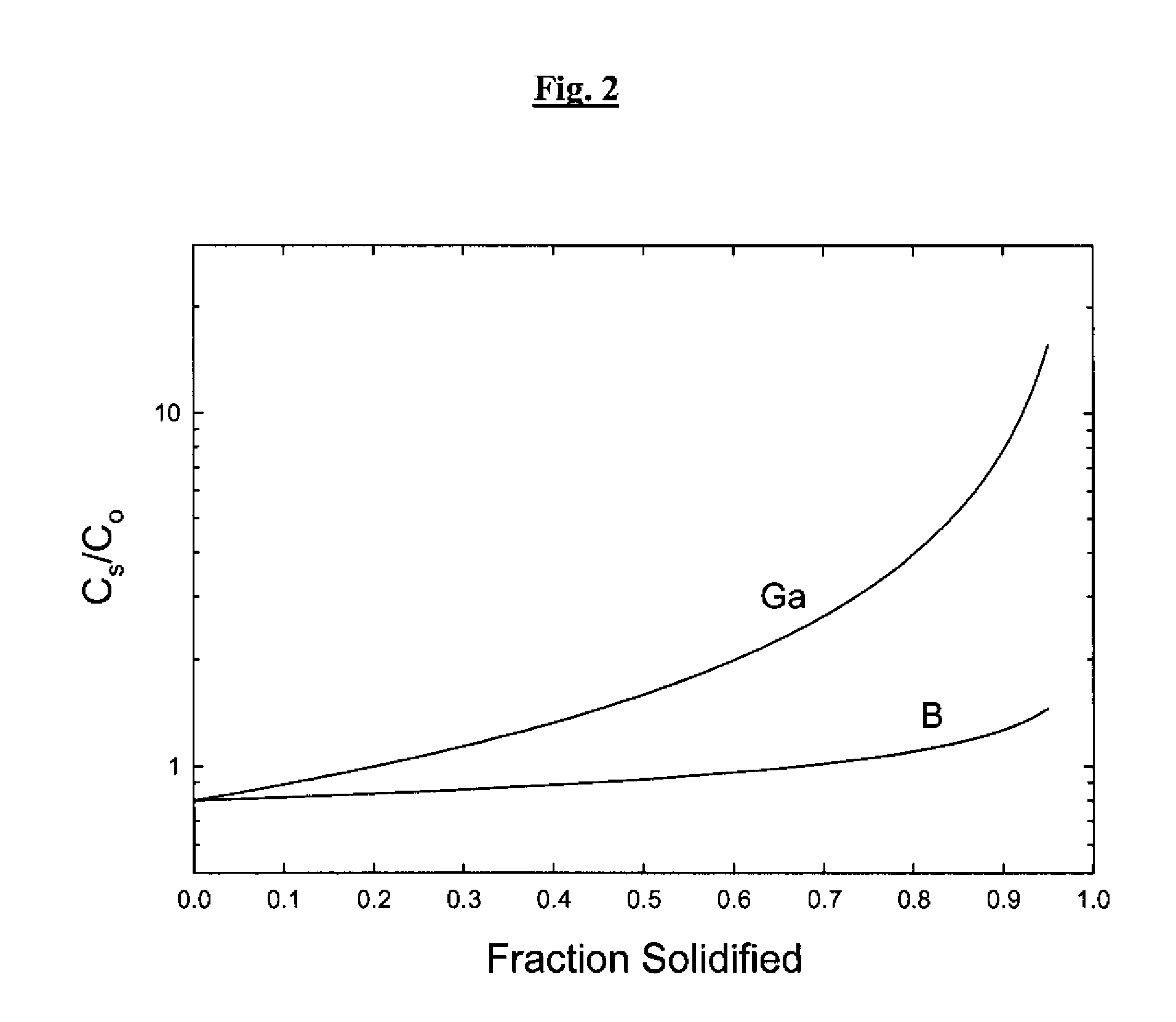

[0021]To improve conversion efficiency of mono-Si solar cells made from p-type substrates, Ga-doped rather than B-doped wafers are used in order to suppress the influence of high concentration oxygen impurity, which is ubiquitous in CZ grown single-crystal Si ingots, on the performance of the solar cells. To obtain p-type mono-Si wafers doped by Ga, it is necessary to grow p-type single-crystal Si ingots with resistivity ranging from 0.1 to 10 Ω-cm using Czochralski method. Ga-doped melt sources may be prepared by mixing Ga dopant at concentrations of approximately from 1×1017 to 2×1019 atoms / cm3 with Si. However, as previously mentioned, achieving uniform distributed doping concentration in Ga-doped Si ingots pulling by CZ method is very difficult. As a result, a small amount of B at a ratio less than one atomic pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com